Preparation method aluminum oxide coating tungsten powder

A technology of alumina and coating powder, which is applied in the field of preparation of composite nano-powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

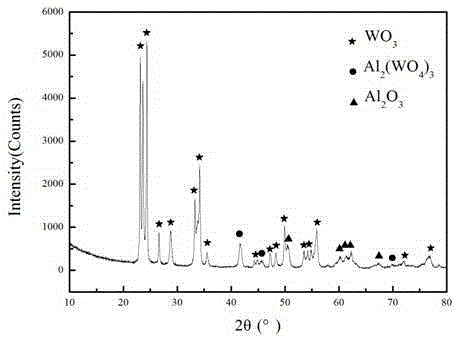

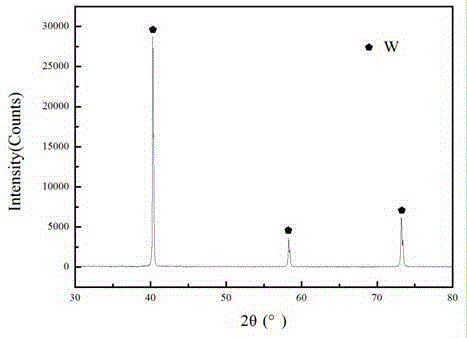

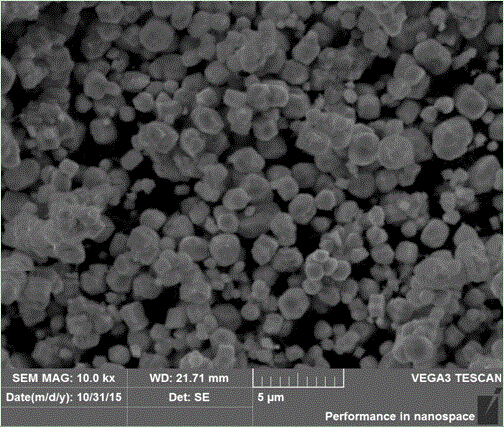

[0044] (1) According to the mass fraction of alumina hydrate in the target coating powder is 0.5%, weigh 30.3g (NH 4 ) 6 h 2 W 12 o 40 , 0.75gAl(NO 3 ) 3 9H 2 O, 40ml dilute HNO 3 , 0.18gCO(NH 2 ) 2 , 40ml of distilled water. Will (NH 4 ) 6 h 2 W 12 o 40 and HNO 3 Put into a hydrothermal kettle for hydrothermal reaction, the temperature of the hydrothermal reaction is 180°C, the time is 10h, and the reaction produces WO 3 and NH 4 NO 3 Mix the solution, and cool the mixed solution to room temperature;

[0045] (2) Al(NO 3 ) 3 , CO(NH 2 ) 2 Put it into another hydrothermal kettle with distilled water, the temperature of hydrothermal reaction is 180°C, the time is 10h, and the reaction generates AlO(OH) and NH 4 NO 3 Mix the solution, and cool the mixed solution to room temperature;

[0046] (3) will WO 3 and NH 4 NO 3 A mixed solution of AlO(OH) and NH 4 NO 3 Pour the mixed solution into a pure beaker and mix and stir in turn. The stirring speed is...

Embodiment 2

[0052] (1) According to the mass fraction of alumina hydrate in the target coating powder is 1.0%, weigh 30.3g (NH 4 ) 6 h 2 W 12 o 40 , 1.65gAl(NO 3 ) 3 9H 2 O, 40mlHNO 3 , 0.4gCO(NH 2 ) 2 , distilled water 40ml; will (NH 4 ) 6 h 2 W 12 o 40 and HNO 3 Put into a hydrothermal kettle for hydrothermal reaction, the temperature of the hydrothermal reaction is 180°C, the time is 10h, and the reaction produces WO 3 and NH 4 NO 3 Mix the solution, and cool the mixed solution to room temperature;

[0053] (2) Al(NO 3 ) 3 , CO(NH 2 ) 2 Put it into another hydrothermal kettle with distilled water for hydrothermal reaction. The temperature of the hydrothermal reaction is 180°C and the time is 10h. The reaction generates AlO(OH) and NH 4 NO 3 Mix the solution, and cool the mixed solution to room temperature;

[0054] (3) will WO 3 and NH 4 NO 3 A mixed solution of AlO(OH) and NH 4 NO 3Pour the mixed solution into a pure beaker and mix and stir in turn. The st...

Embodiment 3

[0060] (1) According to the mass fraction of alumina hydrate in the target coating powder is 3.0%, weigh 30.3g (NH 4 ) 6 h 2 W 12 o 40 , 5.38gAl(NO 3 ) 3 9H 2 O, 40mlHNO 3 , 0.54gCO(NH 2 ) 2 , will (NH 4 ) 6 h 2 W 12 o 40 and HNO 3 Put into a hydrothermal kettle for hydrothermal reaction, the temperature of the hydrothermal reaction is 180°C, the time is 10h, and the reaction produces WO 3 and NH 4 NO 3 Mix the solution, and cool the mixed solution to room temperature;

[0061] (2) Al(NO 3 ) 3 and CO(NH 2 ) 2 Put it into another hydrothermal kettle with distilled water for hydrothermal reaction. The temperature of the hydrothermal reaction is 180°C and the time is 10h. The reaction generates AlO(OH) and NH 4 NO 3 Mix the solution, and cool the mixed solution to room temperature;

[0062] (3) will WO 3 and NH 4 NO 3 A mixed solution of AlO(OH) and NH 4 NO 3 Pour the mixed solution into a pure beaker and mix and stir in turn. The stirring speed is 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com