NiO/WO3 photocatalyst with hierarchical nanostructure, and preparation method and application thereof

A nanostructure and photocatalyst technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, chemical instrument and method, etc., can solve the problem of limited improvement of catalytic efficiency and low photodegradation of organic matter Speed, unable to meet high-tech requirements and other issues, to achieve the effects of improved catalytic efficiency, low cost, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

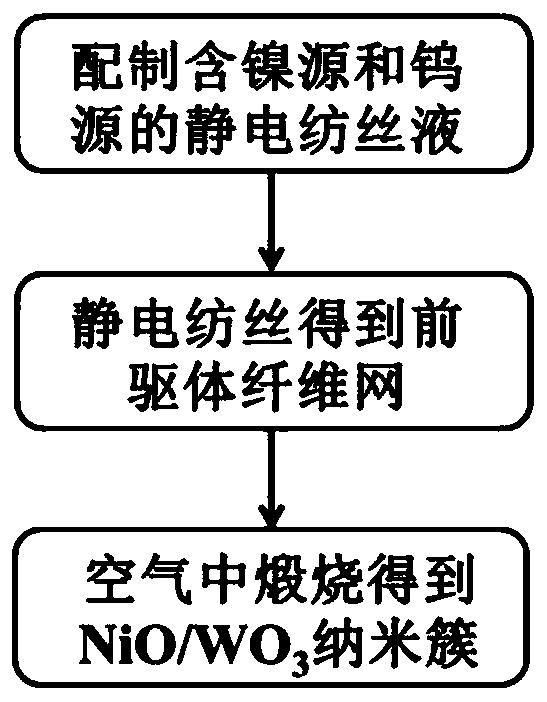

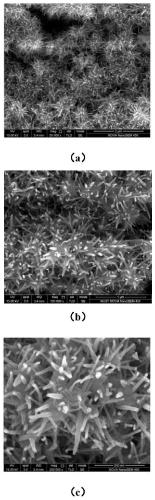

[0051] Such as process figure 1 As shown, first, dissolve 2.0g of nickel nitrate and 2.0g of ammonium metatungstate powder (Ni:W molar ratio is 0.85) in a mixed solvent of 5g of water and 5g of ethanol, stir until fully dissolved and add 2.0g of 1.3 million polyvinylpyrrolidone, continue to stir until clarified to obtain the electrospinning solution; then, transfer the above-mentioned electrospinning solution to the electrospinning machine, set the voltage to 15kV, and the spinning distance is 14cm, and the spinning solution is extruded At a rate of 5mL / h, the precursor nanofiber web containing nickel source and tungsten source can be obtained; finally, the precursor nanofibrous web containing nickel source and tungsten source is calcined in a muffle furnace, and the heating rate is set as 5°C / min, the holding time is 1h, and the holding temperature is 600°C. In situ growth of moss-like NiO / WO on the surface of primary backbone nanofibers after furnace annealing 3 Secondary ...

Embodiment 2

[0056] Such as process figure 1 As shown, first, dissolve 1.5g of nickel nitrate and 2.0g of ammonium metatungstate powder (Ni:W molar ratio is 0.635) in a mixed solvent of 5g of water and 5g of ethanol, stir until fully dissolved and then add 2g of polyvinylpyrrolidone , continue to stir until clarified to obtain the electrospinning solution; then, transfer the above-mentioned electrospinning solution to the electrospinning machine, set the voltage to 15kV, the spinning distance to 14cm, and the extrusion rate of the spinning solution to be 5mL / h, The precursor nanofiber web containing nickel source and tungsten source can be obtained; finally, the precursor nanofibrous web containing nickel source and tungsten source is calcined in a muffle furnace, and the heating rate is set at 5°C / min. The time is 1 h, and the holding temperature is 600°C. In situ growth of moss-like NiO / WO on the surface of primary backbone nanofibers after furnace annealing 3 Secondary nanofiber clust...

Embodiment 3

[0058] Such as process figure 1 As shown, first, dissolve 1.0g of nickel nitrate and 2.0g of ammonium metatungstate powder (Ni:W molar ratio is 0.42) in a mixed solvent of 5g of water and 5g of ethanol, stir until fully dissolved and then add 2g of polyvinylpyrrolidone , continue to stir until clarified to obtain the electrospinning solution; then, transfer the above-mentioned electrospinning solution to the electrospinning machine, set the voltage to 15kV, the spinning distance to 14cm, and the extrusion rate of the spinning solution to be 5mL / h, The precursor nanofiber web containing nickel source and tungsten source can be obtained; finally, the precursor nanofibrous web containing nickel source and tungsten source is calcined in a muffle furnace, and the heating rate is set at 5°C / min. The time is 1 h, and the holding temperature is 600°C. In situ growth of moss-like NiO / WO on the surface of primary backbone nanofibers after furnace annealing 3 Secondary nanofiber cluste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com