Method for sorting high-phosphorus iron ore by combining microwave reduction roasting and low intensity magnetic separation

A technology for iron ore, weak magnetic separation, applied in magnetic separation, chemical instruments and methods, solid separation, etc., can solve the problems of small changes in ore structure, large iron powder, high energy consumption, and improve the structure of difficult-to-separate ore , Reduce the energy consumption of grinding, and improve the effect of sorting indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

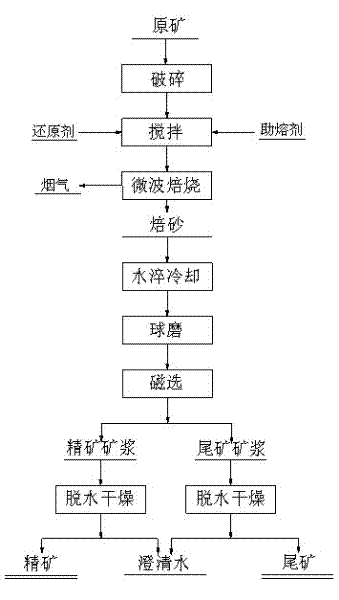

Image

Examples

Embodiment 1

[0031] Example 1: The grade TFe of the refractory high-phosphorus iron ore ore is 29.74%, and the phosphorus content is 1.07%, which is mainly disseminated. The process steps of microwave reduction roasting combined with weak magnetic separation are:

[0032] (1) Use an ordinary crusher to crush the ore to a particle size below 2mm;

[0033] (2) Take 500g of the crushed raw ore, add 100g of commercially available caustic soda with a purity of 98wt% and 40g of Yunnan anthracite powder with a fixed carbon content of 60wt%, and stir and mix well;

[0034] (3) Send the obtained mixture into the microwave reaction furnace, adjust the temperature control device to operate the microwave reaction furnace, control the heating rate to 100°C / min, and heat the mixture to 700°C (set the heating temperature to 700°C) , Keep the temperature for 3 minutes, and reduce and roast the mixture;

[0035] (4) Water-quench the mineral material obtained after roasting in step (3) to quickly cool it to room t...

Embodiment 2

[0039] Example 2: The grade TFe of the refractory high-phosphorus iron ore ore is 28.70%, and the phosphorus content is 1.05%. The process steps of microwave reduction roasting combined with weak magnetic separation are:

[0040] (1) Use an ordinary crusher to crush the ore to a particle size below 5mm;

[0041] (2) Take 100g of the crushed ore, add 15g of commercially available caustic soda with a purity of 95wt% and 10g of anthracite powder with a fixed carbon content of 61wt%, and mix them thoroughly;

[0042] (3) Send the obtained mixture into the microwave reaction furnace, adjust the temperature control device to operate the microwave reaction furnace, control the heating rate to 80°C / min, and heat the mixture to 800°C (set the heating temperature to 800°C) , Keep the temperature for another 2 minutes, and reduce and roast the mixture;

[0043] (4) Water quenching the mineral material obtained after roasting in step (3) to quickly cool it to room temperature;

[0044] (5) Send t...

Embodiment 3

[0046] Example 3: The grade TFe of the refractory high-phosphorus iron ore ore is 28.10%, and the phosphorus content is 1.2%. The process steps of microwave reduction roasting combined with weak magnetic separation are:

[0047] (1) Use an ordinary crusher to crush the raw ore to a particle size less than 5mm;

[0048] (2) Take 1000g of the crushed ore, add 30g of caustic soda with a purity of 85% by weight, 60g of anthracite powder with a fixed carbon content of 63% by weight, and mix them thoroughly;

[0049] (3) Send the obtained mixture into the microwave reaction furnace, adjust the temperature control device to operate the microwave reaction furnace, control the heating rate to 100°C / min, and heat the mixture to 600°C (set the heating temperature to 600°C) , Keep the temperature for another 2 minutes, and reduce and roast the mixture;

[0050] (4) Water quenching the mineral material obtained after roasting in step (3) to quickly cool it to room temperature;

[0051] (5) Feed th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com