Hybrid film coating method of neodymium iron boron rare earth permanent magnet device

A hybrid coating, rare earth permanent magnet technology, applied in magnetic materials, electrical components, sputtering and other directions, can solve the problems of poor adhesion between the film and the substrate, high energy consumption and pollution, and low magnetron sputtering efficiency. , to improve the magnetic energy product and coercive force, improve the corrosion resistance, and reduce the amount of rare earth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

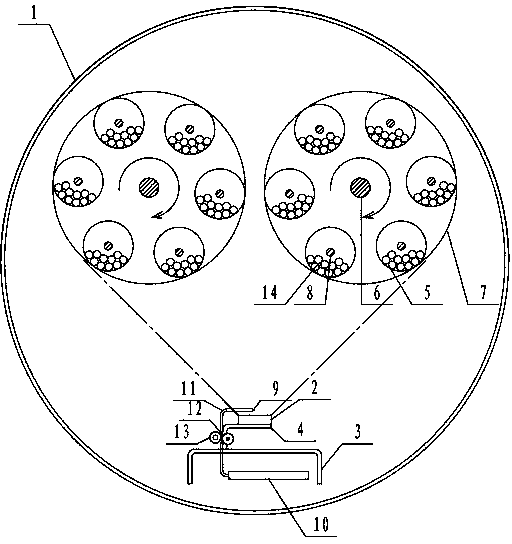

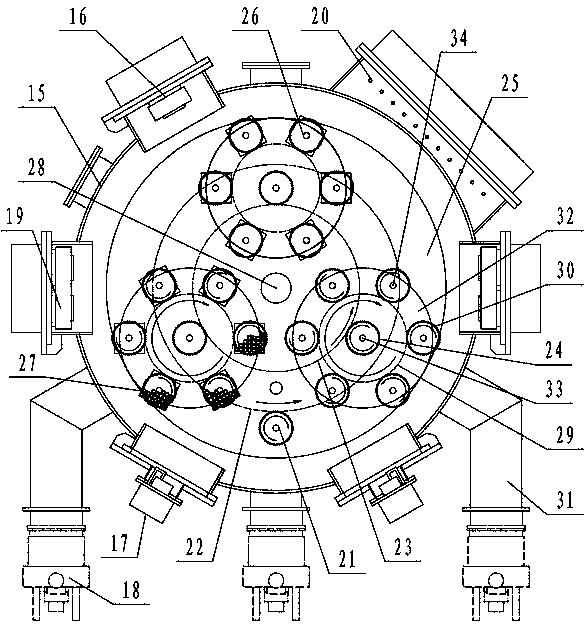

Image

Examples

Embodiment 1

[0048] Manufactured as follows:

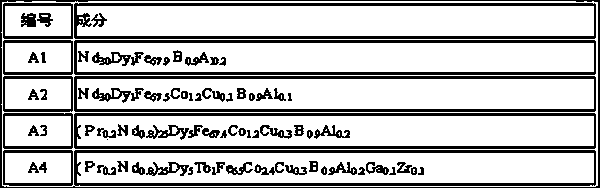

[0049] 1. Select 600Kg of alloys according to the composition of A1, A2, A3, and A4 in Table 1 for smelting. In the molten state, cast the alloy on a rotating copper roller with water cooling to cool to form alloy flakes, then carry out hydrogen crushing, and then carry out mixing after hydrogen crushing. After mixing the materials, jet milling is carried out, and then the materials are mixed with a mixer under the protection of nitrogen, and then sent to the nitrogen protection magnetic field orientation press for molding. The oxygen content in the protection box is 150ppm, the orientation magnetic field strength is 1.8T, and the temperature in the mold cavity is 2 ℃, the size of the magnetic block is 62×52×42mm, and the orientation direction is the 42-dimensional direction. After forming, it is packaged in a protective box, and then taken out for isostatic pressing. The isostatic pressing pressure is 200MPa, and then sent to the sintering equ...

Embodiment 2

[0061] Select the composition in embodiment 1 to make NdFeB rare earth permanent magnet device, the coating selects the first layer of Dy-Al alloy plating, the second layer of Al+Al plating, and the third layer of Al plating for temperature experiments, and the results are listed in Table 4 , No. 1 is the comparative example without heating or heat treatment during coating. It can be seen from Table 4 that the coating temperature and the heat treatment temperature after coating have an impact on the magnetic properties of the material, which significantly improves the coercive force of the magnet, that is, The use temperature of the magnet is increased, and at the same use temperature, the amount of heavy rare earths can be reduced, saving scarce resources.

[0062] Table 4. Effect of coating temperature and heat treatment temperature on magnetic properties and corrosion resistance

[0063]

[0064] Note: 1. Corrosion resistance (PCT test)

[0065] Experimental cond...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com