High rigidness saturated polarity rubber adhesive permanent magnet and preparation thereof

A technology for bonding permanent magnets and polar rubber, which is applied in the direction of magnetic objects, magnetic materials, inorganic materials, etc., to achieve the effects of improving product hardness, improving physical properties, and reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

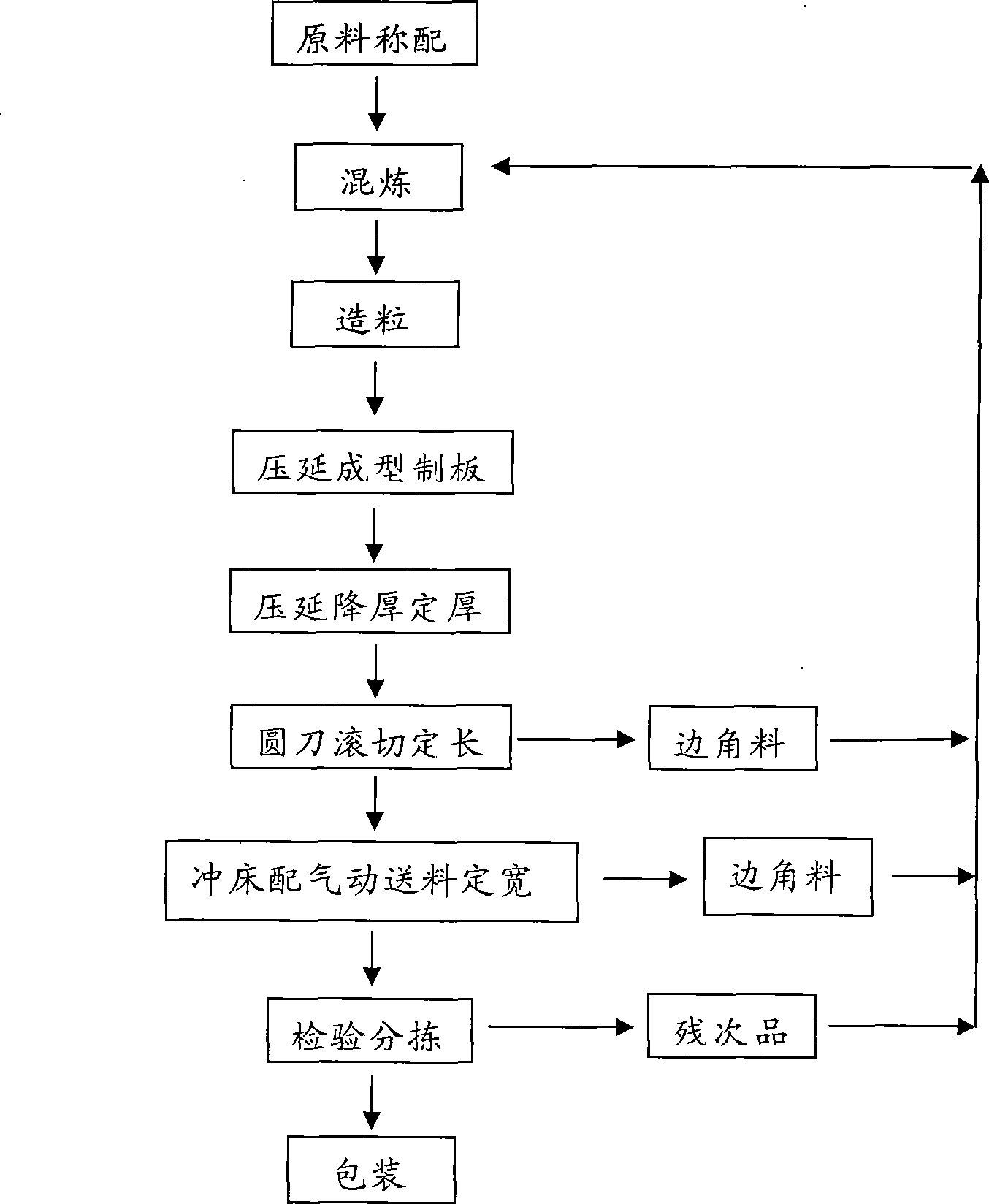

Image

Examples

Embodiment 1

[0047] Zhejiang Ante Magnetic Material Co., Ltd. magnetic powder ZMXF-4S strontium ferrite bonded magnetic powder 1200 parts, Nantong Hengrui Glass Plastic Co., Ltd. 130A type CPE 100 parts, plasticizer 25 parts, Rugao Shuangma Chemical Co., Ltd. 401820 type stearic acid 15 parts, 0.5 part of calcium stearate from Nantong Xinbang Chemical Co., Ltd., 0.3 part of KY405-L anti-aging agent, after mixing evenly, knead with an open mill for 5 minutes, and the hardness of the obtained film is Shore 53 Shore D.

Embodiment 2

[0049] Beikuang Magnetic Materials Co., Ltd. BMXF-4B strontium ferrite bonded magnetic powder 140Kg, Nantong Hengrui Glass Plastic Co., Ltd. 130A type CPE 10.8Kg, plasticizer 2.8Kg, stearic acid 1.5Kg, calcium stearate 0.5Kg , anti-aging agent 0.3Kg, through 55 liters of pressurized kneader with top bolt, mixed according to the above method, and discharged, the film hardness 53 Shore D was obtained.

Embodiment 3

[0051] Zhejiang Ante Magnetic Materials Co., Ltd. BMXF-4S magnetic powder 1350 parts, Nantong Hengrui Glass Plastic Manufacturing Co., Ltd. 130A type CPE 100 parts, plasticizer 28 parts, 401820 type stearic acid 15 parts, calcium stearate 0.5 parts, KY- 0.3 part of 405 anti-aging agent was mixed with a 55-liter internal mixer, and the film hardness of 54 Shore D was obtained after discharging.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com