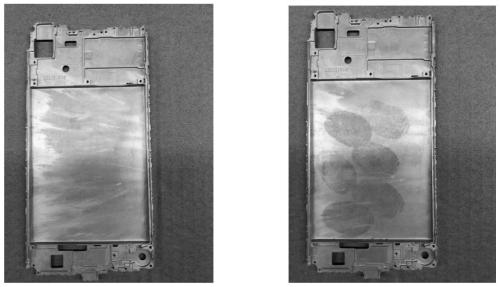

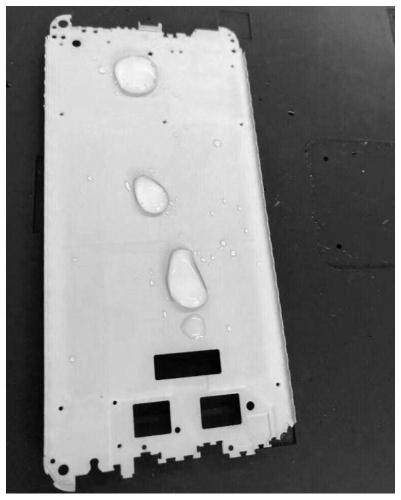

High-hardness scratch-proof and fingerprint-resistant sealant on metal surface

A metal surface and sealing agent technology, which is applied in the direction of anti-corrosion coatings, fire-proof coatings, paints containing biocides, etc., can solve problems that affect the application and development of magnesium alloys, reduce product qualification rate, product corrosion and scrapping, etc., to achieve film and The effect of strong paint bonding, improved pass rate, and improved product hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] A high-hardness, scratch-resistant and fingerprint-resistant sealant for metal surfaces. The raw materials include water-based resin, water-based silicone oil, fatty alcohol polyether, alkaline reagent, and solvent;

[0060] The preparation method of the sealing agent comprises the following steps: weighing each component, adding a solvent into a container, adding an alkali reagent and stirring to dissolve evenly, then adding water-based resin and water-based silicone oil, stirring and dissolving evenly, and finally adding fatty alcohol polyether, The temperature is raised to 50°C, and the sealing agent is obtained by stirring evenly;

[0061] The weight ratio of the water-based resin and fatty alcohol polyether is 1:0.05; the added mass of the solvent is 94.9% of the total mass of raw materials; the water-based resin is an anionic water-based polyurethane resin with a viscosity of 300mPa.s, purchased from Anhui Anda Huatai New Material Co., Ltd., the model is AH-1605B;...

Embodiment 2

[0063] A high-hardness, scratch-resistant and fingerprint-resistant sealant for metal surfaces. The raw materials include water-based resin, water-based silicone oil, fatty alcohol polyether, alkaline reagent, and solvent;

[0064] The preparation method of the sealing agent comprises the following steps: weighing each component, adding a solvent into a container, adding an alkali reagent and stirring to dissolve evenly, then adding water-based resin and water-based silicone oil, stirring and dissolving evenly, and finally adding fatty alcohol polyether, The temperature is raised to 30°C, and the sealing agent is obtained by stirring evenly;

[0065] The weight ratio of the water-based resin and fatty alcohol polyether is 1:0.01; the added mass of the solvent is 80% of the total mass of raw materials; the water-based resin is an anionic water-based polyurethane resin with a viscosity of 100mPa.s, purchased from Anhui Anda Huatai New Material Co., Ltd., the model is AH-1605B; t...

Embodiment 3

[0067] A high-hardness, scratch-resistant and fingerprint-resistant sealant for metal surfaces. The raw materials include water-based resin, water-based silicone oil, fatty alcohol polyether, alkaline reagent, and solvent;

[0068] The preparation method of the sealing agent comprises the following steps: weighing each component, adding a solvent into a container, adding an alkali reagent and stirring to dissolve evenly, then adding water-based resin and water-based silicone oil, stirring and dissolving evenly, and finally adding fatty alcohol polyether, The temperature is raised to 70°C, and the sealing agent is obtained by stirring evenly;

[0069] The weight ratio of the water-based resin and fatty alcohol polyether is 1:0.1; the added mass of the solvent is 98% of the total mass of raw materials; the water-based resin is an anionic water-based polyurethane resin with a viscosity of 500mPa.s, purchased from Anhui Anda Huatai New Material Co., Ltd., the model is AH-0201D; th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com