Multilayer-coated soft magnetic composite material and preparation method thereof

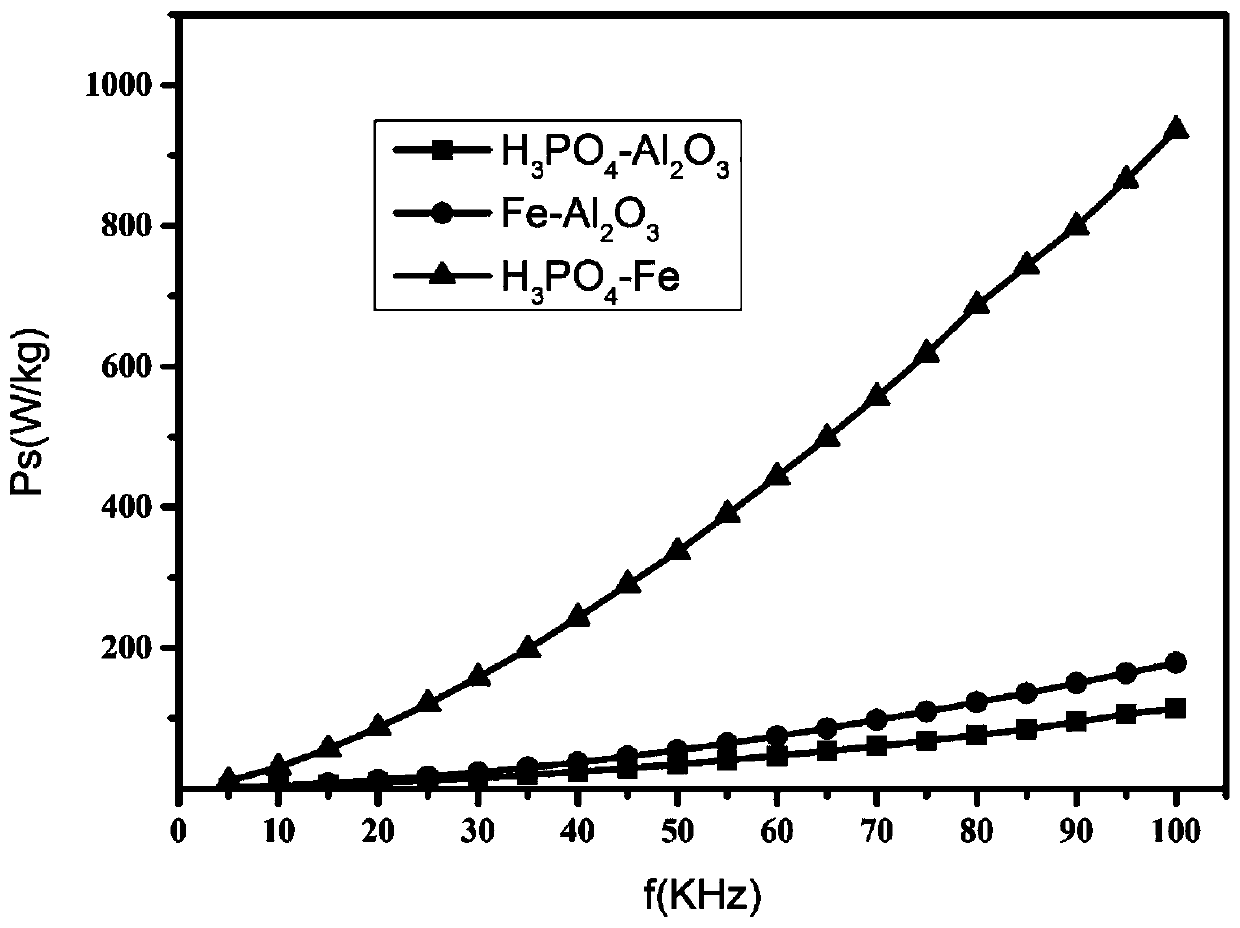

A soft magnetic composite material and multi-layer coating technology, which is applied in the direction of inorganic material magnetism, inductance/transformer/magnet manufacturing, electrical components, etc., can solve the problems of reducing the magnetic properties of composite materials and large eddy current losses, and achieve the improvement of heat treatment temperature , The effect of low eddy current loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

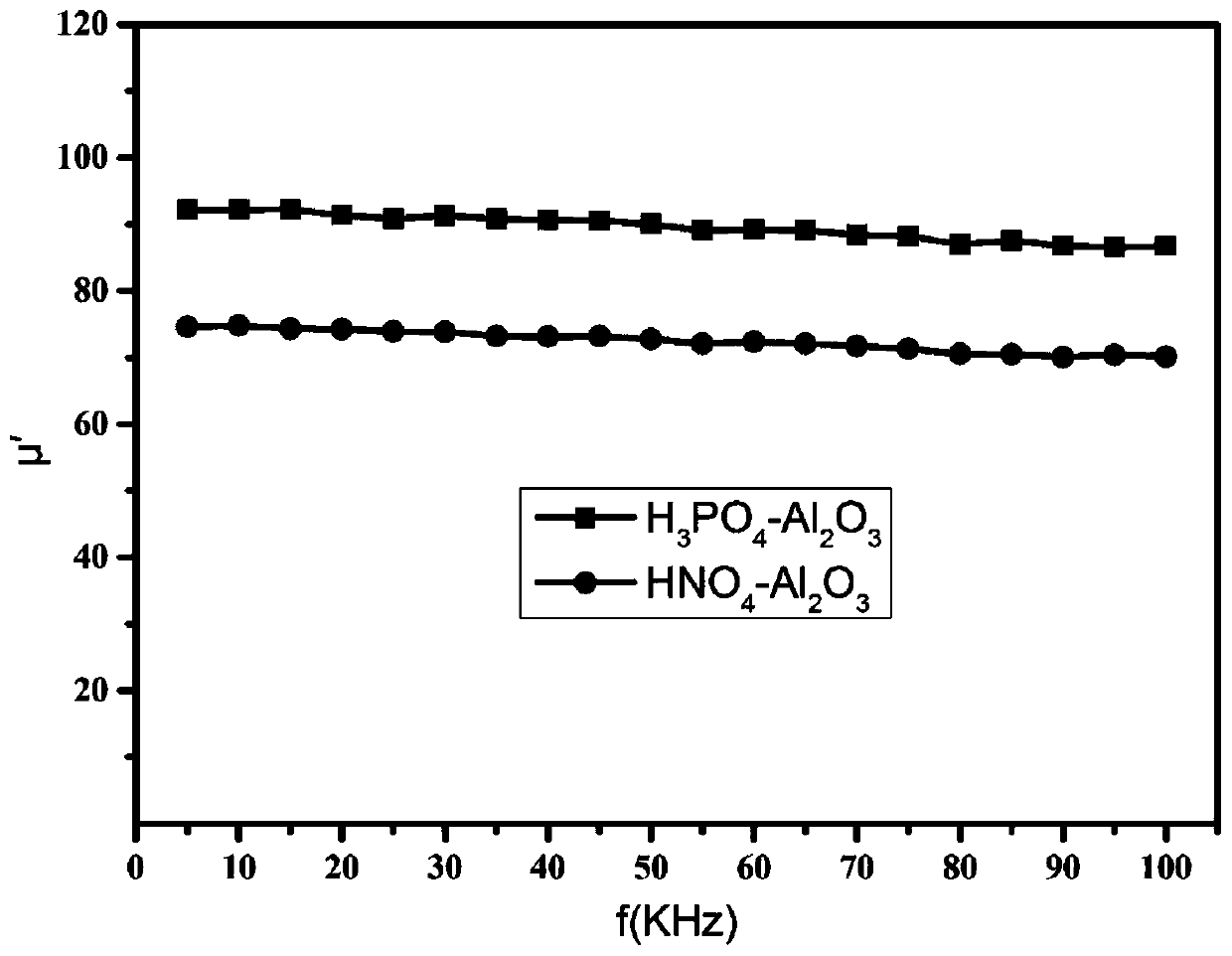

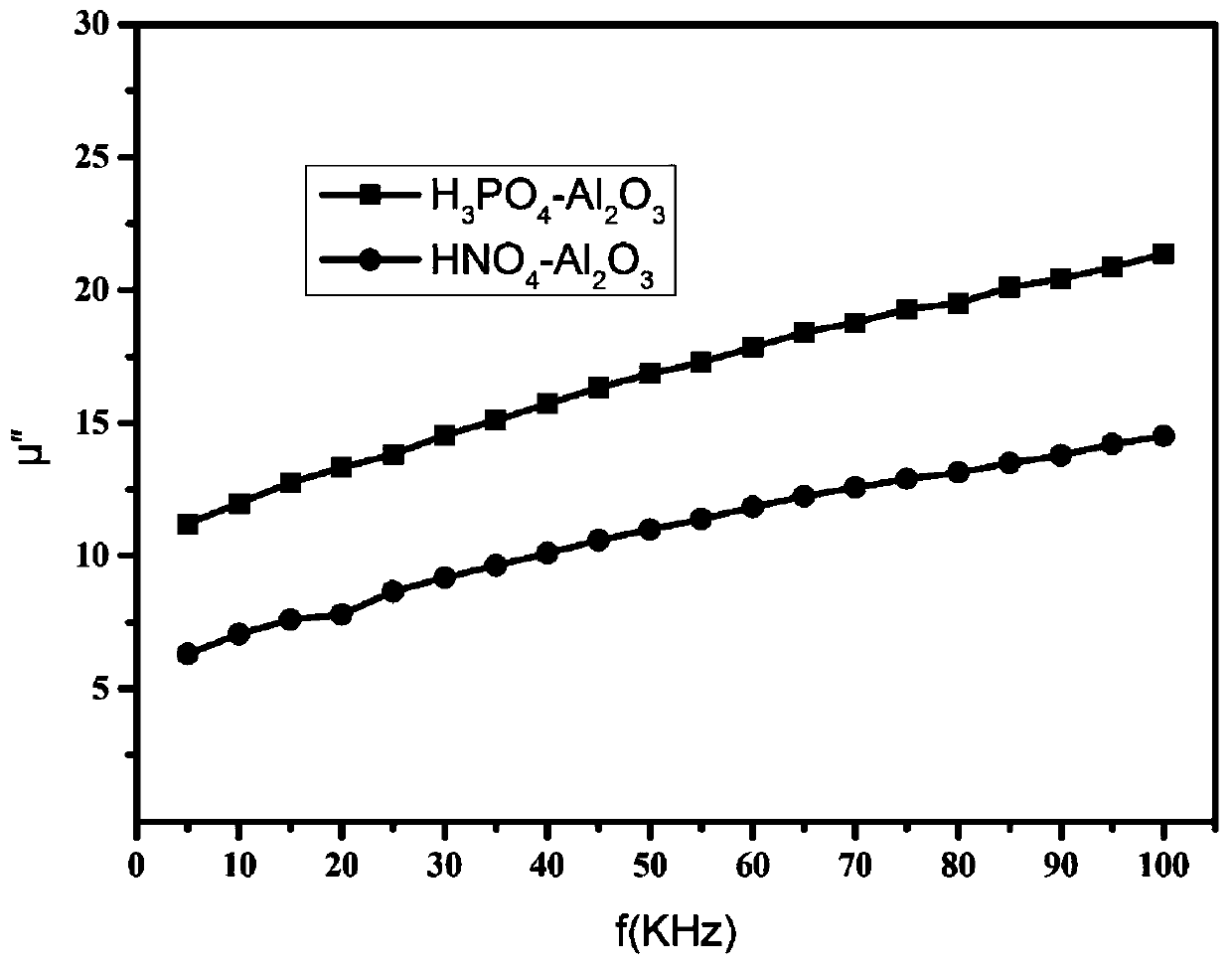

Embodiment 1

[0060] A method for preparing a multilayer coated soft magnetic composite material, comprising the following steps:

[0061] (1) take by weighing the Fe powder of 50g, put into beaker;

[0062] (2) Measure 0.7ml of phosphoric acid and 99.3ml of alcohol respectively, and slowly add the passivating agent into the alcohol to make a passivating solution of 0.012g / ml;

[0063] (3) Measure 15ml of the phosphoric acid passivation solution, add it into a beaker, put it into a constant temperature water bath at 65°C, stir until the solution is completely evaporated to dryness, and obtain powder A;

[0064] The Al 2 o 3 The preparation of colloid comprises the steps:

[0065] (4) Take by weighing 4.0048g aluminum isopropoxide (grinding), put into beaker A after weighing;

[0066] (5) Measure 50ml of ethylene glycol ether in a graduated cylinder, add it to beaker A, and stir magnetically at 60°C for 30 minutes;

[0067] (6) Weigh 2.0024g of acetylacetone, slowly add it into beaker A...

Embodiment 2

[0079] A method for preparing a multilayer coated soft magnetic composite material, comprising the following steps:

[0080] (1) take by weighing the Fe powder of 50g, put into beaker;

[0081] (2) Measure 0.7ml of nitric acid and 99.3ml of alcohol respectively, and slowly add the passivating agent into the alcohol to make a passivating solution of 0.012g / ml;

[0082] (3) Measure 15ml of nitric acid passivation solution, add it into a beaker, put it into a constant temperature water bath at 65°C, stir until the solution is completely evaporated to dryness, and obtain powder A;

[0083] The Al 2 o 3 The preparation of colloid comprises the steps:

[0084] (4) Take by weighing 4.0048g aluminum isopropoxide (grinding), put into beaker A after weighing;

[0085] (5) Measure 50ml of ethylene glycol ether in a graduated cylinder, add it to beaker A, and stir magnetically at 60°C for 30 minutes;

[0086] (6) Weigh 2.0024g of acetylacetone, slowly add it into beaker A, and stir m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com