Ni-base alloy composite base band prepared by hot isostatic pressing method

A technology of hot isostatic pressing and composite base tape, applied in the direction of rolling force/roll gap control, etc., which can solve the problems of low magnetic properties, easy cracking of the surface layer and core layer, and difficulty in obtaining composite base tape.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

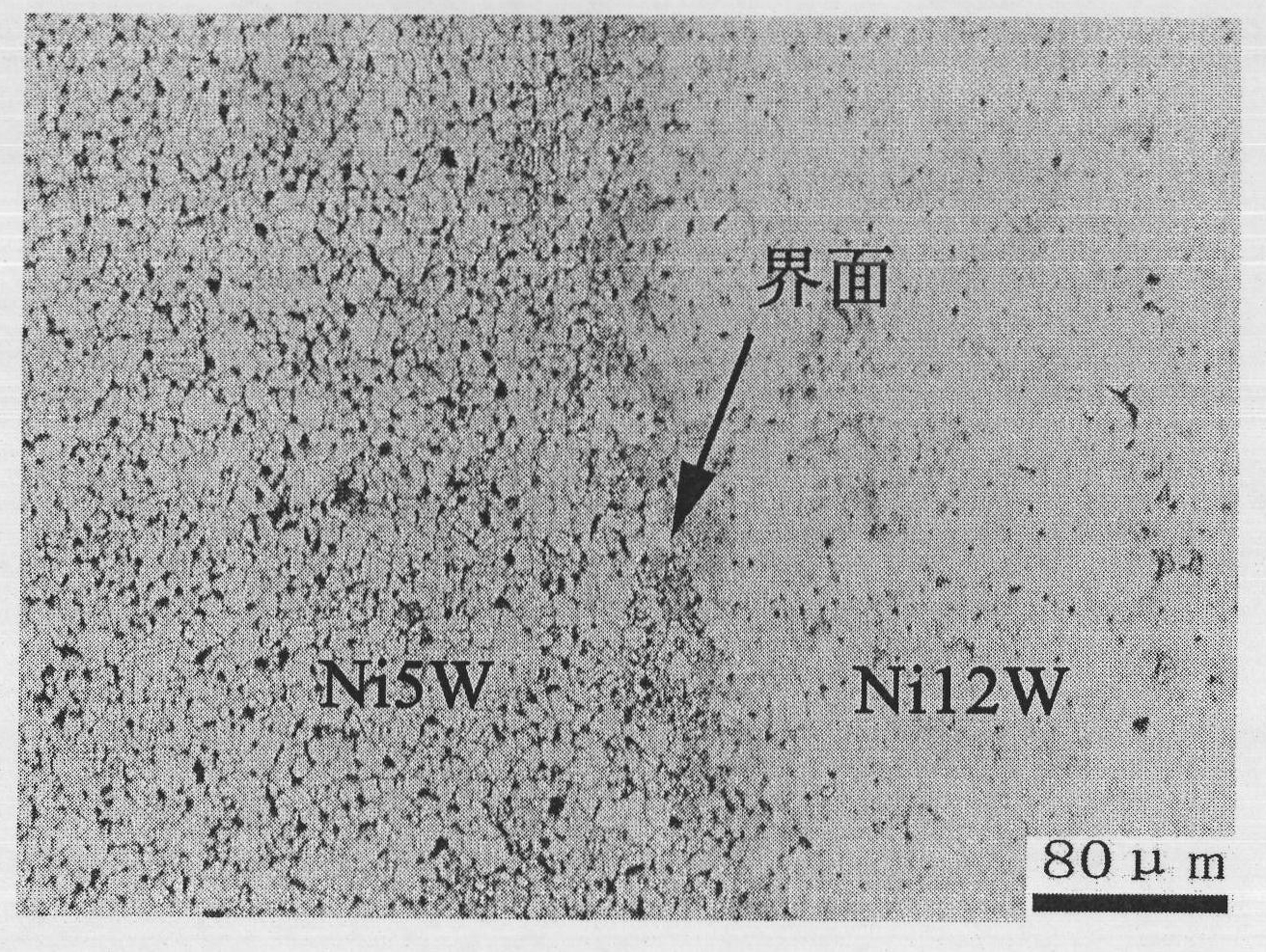

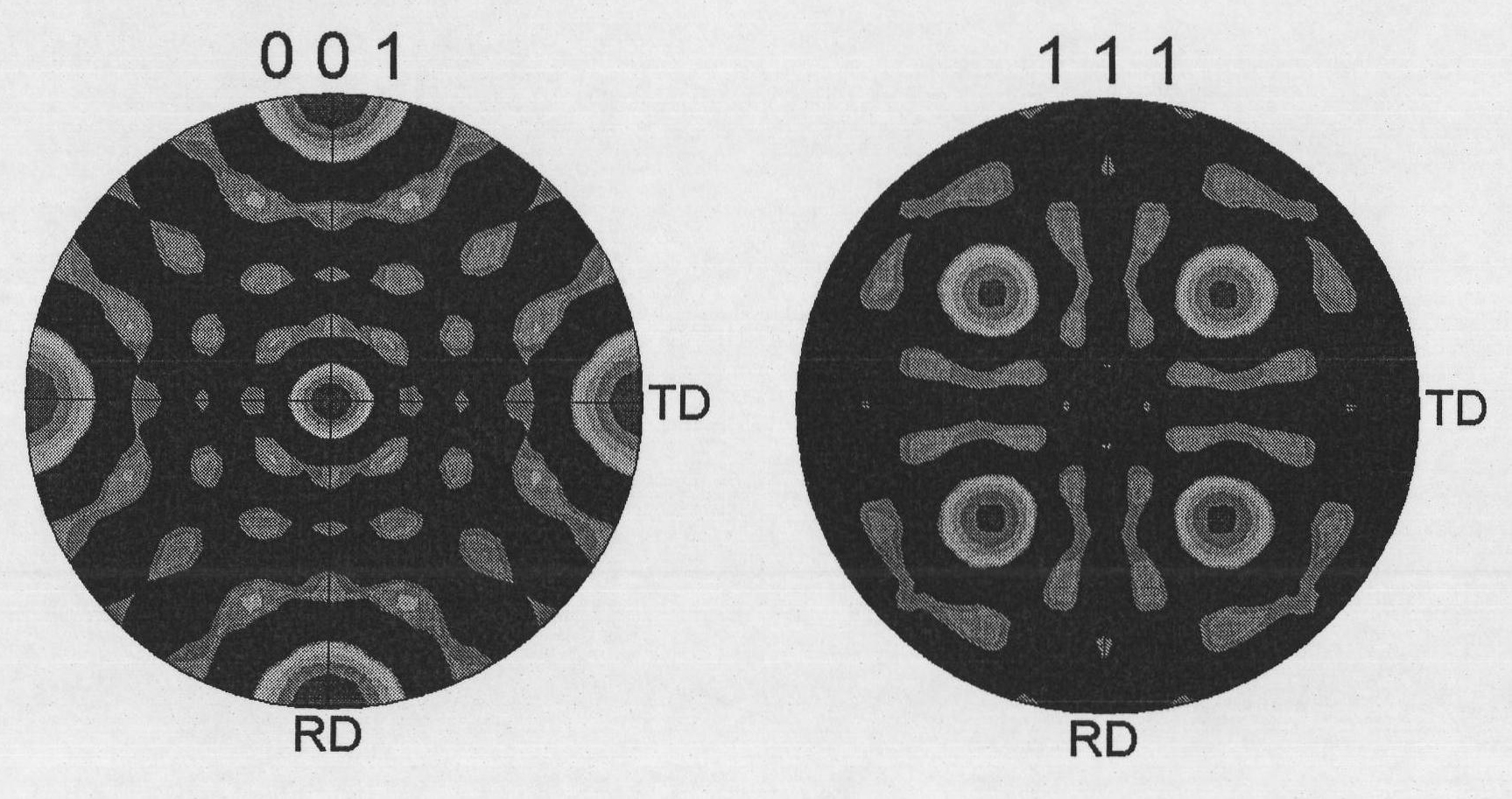

[0024] Grind the NiW powder (code named A powder) with 5 atomic percent of W and the NiW powder (code named B powder) with 12 atomic percent of W respectively, and grind the powder according to A-B-A Sequential layering is placed in the mold; then the above-mentioned layered powder is placed in the mold by traditional powder metallurgy cold isostatic pressing, wherein the pressure is 250MPa, and the pressure is kept for 5 minutes; then the billet is put into the mold according to its size In the designed sheath, after vacuum sealing and welding; then put the sheath into the hot isostatic pressing sintering equipment for homogenization treatment, the sintering temperature is 1200 ℃, the pressure is 130MPa (the working medium is pure Ar), heat preservation Holding time is 10 hours, obtains initial composite ingot, and the metallographic diagram of this composite ingot is as follows figure 1 Shown; The composite billet that is fired is carried out cold-rolling, and the pass defor...

Embodiment 2

[0026] Grind the NiW powder (code named A powder) with 5 atomic percent of W and the NiW powder (code named B powder) with 12 atomic percent of W respectively, and grind the powder according to A-B-A Sequential layering is placed in the mold; then the powder that has been layered in the mold is formed by traditional powder metallurgy cold isostatic pressing, wherein the pressure is 250MPa, and the pressure is maintained for 5min; subsequently, the formed compact is placed in Ar / h 2 Sinter at 1000°C for 5 hours in a protective atmosphere, then put the ingot into a sheath designed according to its size, vacuum seal and weld, then put the sheath into a hot isostatic pressing sintering equipment for homogenization treatment, The sintering temperature is 1200°C, the pressure is 150MPa (the working medium is pure Ar), and the heat preservation and pressure holding time is 6 hours; the sintered composite billet is cold-rolled, and the deformation of each pass is 3-15%, and the total...

Embodiment 3

[0028] Grind the NiW powder (code named A powder) with 5 atomic percent of W and the NiW powder (code named B powder) with 12 atomic percent of W respectively, and grind the powder according to A-B-A Sequential layering is placed in the mold; then the powder that has been layered in the mold is formed by traditional powder metallurgy cold isostatic pressing, wherein the pressure is 250MPa, and the pressure is maintained for 5min; subsequently, the formed compact is placed in Ar / h 2 Sinter at 1000°C for 5 hours in a protective atmosphere, and then put the ingot into a hot isostatic pressing sintering equipment for homogenization treatment. The sintering temperature is 1200°C, the pressure is 80MPa (the working medium is pure Ar), and the holding time is 3 hours; the fired composite ingot is cold-rolled, the pass deformation is 3-15%, and the total deformation is greater than 95%, and the thickness is 100um cold-rolled base strip; the cold-rolled base strip is in Ar / H 2Anneali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com