Blank formulation for generating tile decorative building materials by carbon black coloring and manufacturing method

A technology of carbon black and bricks and tiles, which is applied in the firing field of building ceramics and decorative tiles, and can solve problems such as increased production costs, low production output, and restricted output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

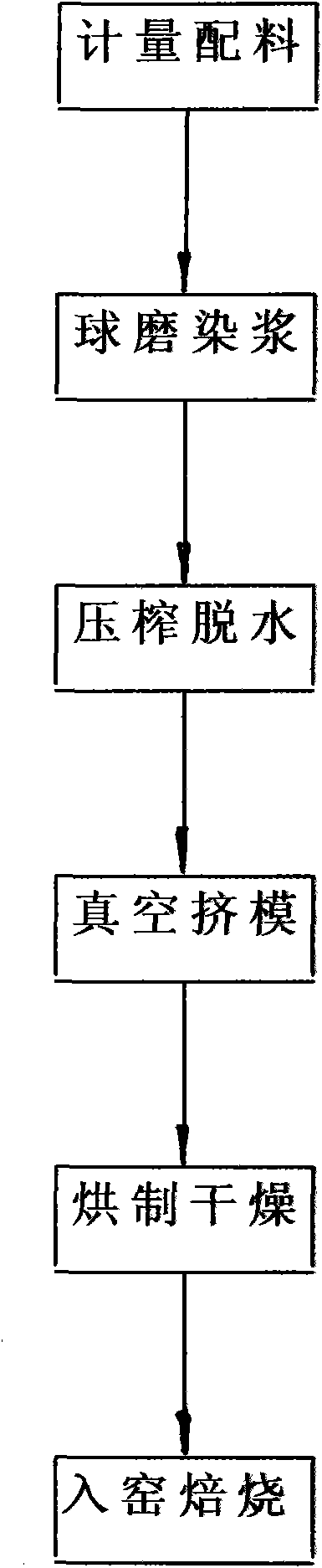

Method used

Image

Examples

Embodiment 1

[0075] A blank formula for producing green roof tile series products, which is composed of the following raw materials in weight ratio:

[0076] Carbon black 1 part,

[0077] 42 parts of vanadium titanium slag,

[0078] Soft shale 42 parts.

[0079] The above-mentioned carbon black is a commercially available chemical product as a coloring agent.

[0080] The vanadium-titanium slag mentioned above refers to the slag waste discharged from the smelting of vanadium-titanium alloy by Panzhihua Iron and Steel Company.

[0081] The aforementioned soft shale refers to soft carbonaceous shale and / or black shale containing a large amount of carbonized organic matter and finely dispersed iron sulfide.

Embodiment 2

[0083] A billet formula for producing green roof tile series products, characterized in that it consists of the following raw materials in weight ratio:

[0084] Carbon black 1 part,

[0085] 45 parts of vanadium-titanium slag,

[0086] Soft clay 50 parts.

[0087] The soft clay mentioned above refers to the muddy soil of weak cohesive soil.

Embodiment 3

[0089] A raw material formula for producing series of black wall tiles and black floor tiles, characterized in that it is made of the following raw materials in weight ratio:

[0090] Carbon black 1 part,

[0091] Iron powder 25 parts,

[0092] 30 parts of soft shale,

[0093] 30 parts of soft clay.

[0094] The above-mentioned iron powder refers to the black powdery waste material discharged in the process of smelting iron products.

[0095] The aforementioned soft shale refers to soft carbonaceous shale and / or black shale.

[0096] The soft clay mentioned above refers to the muddy soil of weak cohesive soil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com