Continuous casting and rolling method and device for producing glass ceramics by utilizing blast-furnace slag

A technology of blast furnace slag and glass ceramics, applied in the fields of metallurgy and inorganic non-metallic materials, to reduce excessive consumption, increase economic profits, and reduce waste water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

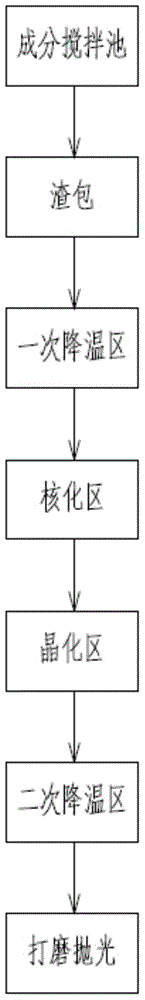

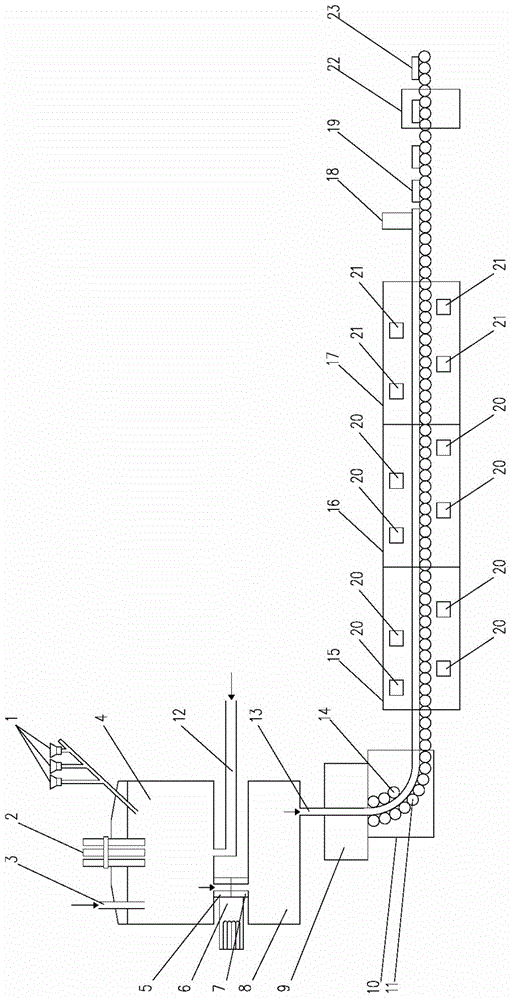

[0079] The blast furnace slag provided by the present embodiment prepares glass-ceramic comprising the following steps:

[0080] (1) The 1500°C molten slag flowing out of the blast furnace is transferred to the composition stirring pool through the iron mixing furnace for heating and heat preservation;

[0081] (2) Add the component modifier into the component stirring tank, blow inert gas and coal powder from the top and bottom to mix the components evenly and keep the temperature at 1450-1500°C for 1 hour;

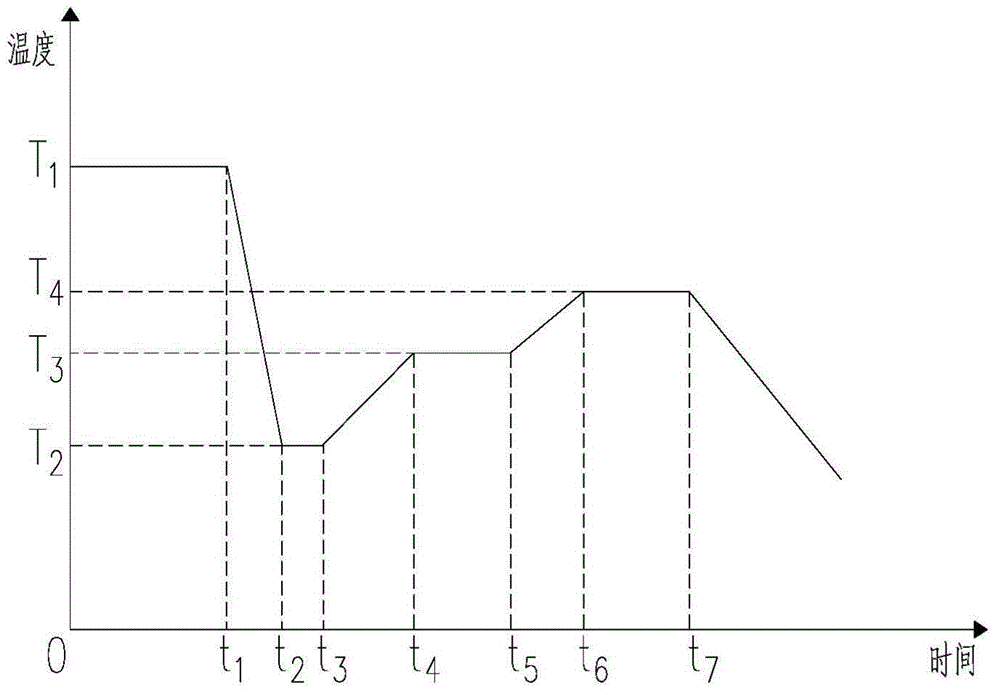

[0082] (3) The slag enters the primary cooling zone, spraying high-pressure cooling water on both sides of the roller table to quickly cool the shell to below 900°C for vitrification, and enter the nucleation zone before the surface of the shell is not lower than 500°C;

[0083] (4) Raise the temperature of the product to 800°C at a heating rate of 10°C / min, and keep it warm for 2.5 hours before entering the crystallization zone;

[0084] (5) Raise the temperature of th...

Embodiment 2

[0089] The blast furnace slag provided by the present embodiment prepares glass-ceramic comprising the following steps:

[0090] (1) The 1500°C molten slag flowing out of the blast furnace is transferred to the composition stirring pool through the iron mixing furnace for heating and heat preservation;

[0091] (2) Add component modifiers, nucleating agents, etc. into the component stirring tank, blow inert gas and coal powder from the top and bottom to mix the components evenly and keep the temperature at 1450-1500°C for 1 hour;

[0092] (3) The slag enters the primary cooling zone, spraying high-pressure cooling water on both sides of the roller table to quickly cool the shell to below 900°C for vitrification, and enter the nucleation zone before the surface of the shell is not lower than 500°C;

[0093] (4) Raise the temperature of the product to 780°C at a heating rate of 10°C / min, and keep it warm for 2 hours before entering the crystallization zone;

[0094] (5) Raise t...

Embodiment 3

[0099] The blast furnace slag provided by the present embodiment prepares glass-ceramic comprising the following steps:

[0100] (1) The 1500°C molten slag flowing out of the blast furnace is transferred to the composition stirring pool through the iron mixing furnace for heating and heat preservation;

[0101] (2) Add component modifiers, nucleating agents, etc. into the component stirring tank, blow inert gas and coal powder from the top and bottom to mix the components evenly and keep the temperature at 1450-1500°C for 1 hour;

[0102] (3) The slag enters the primary cooling zone, spraying high-pressure cooling water on both sides of the roller table to quickly cool the shell to below 900°C for vitrification, and enter the nucleation zone before the surface of the shell is not lower than 500°C;

[0103] (4) Raise the temperature of the product to 740°C at a heating rate of 10°C / min, and keep it warm for 1.5 hours before entering the crystallization zone;

[0104] (5) Raise...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com