Patents

Literature

90results about How to "Reduce excessive consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

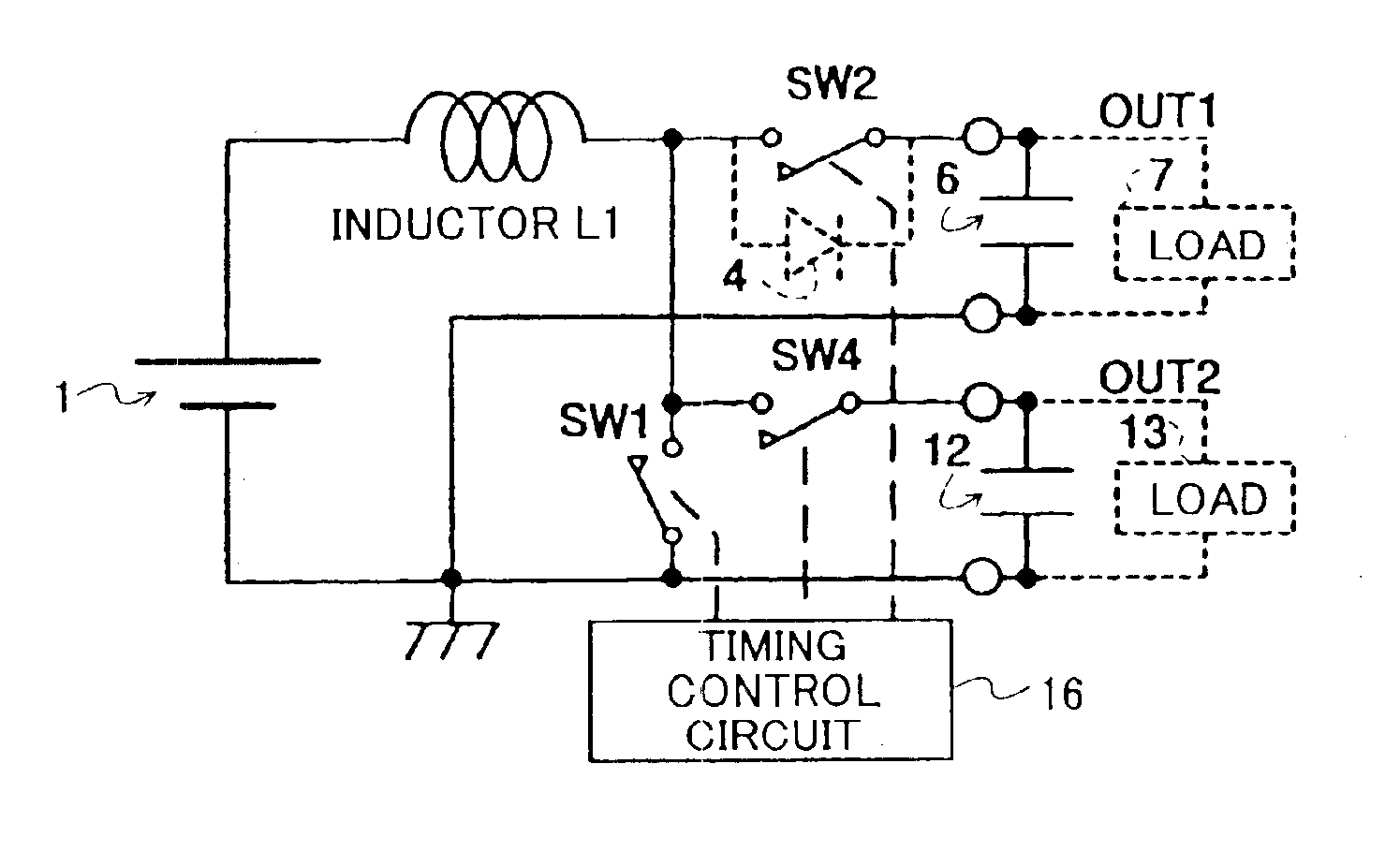

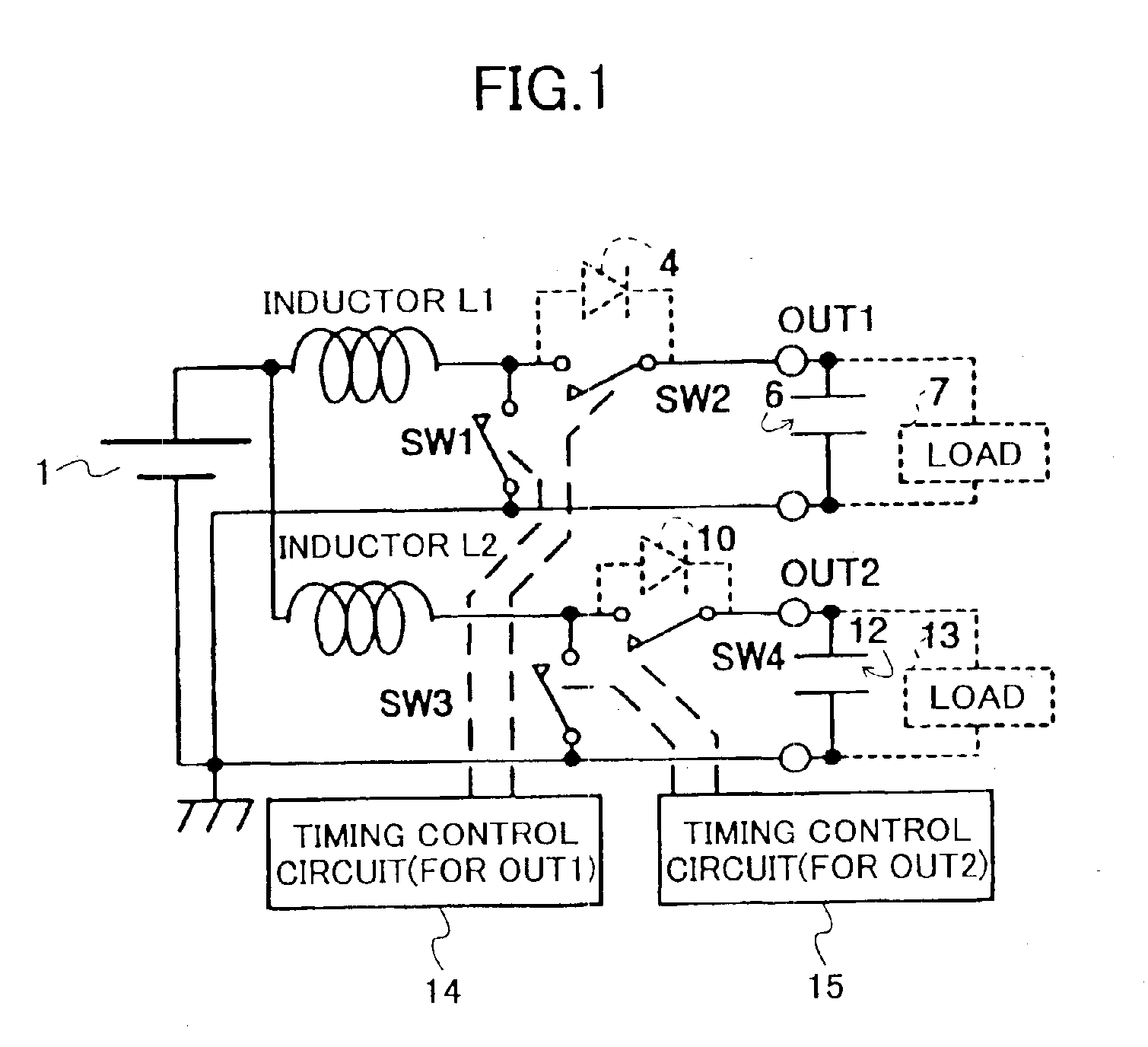

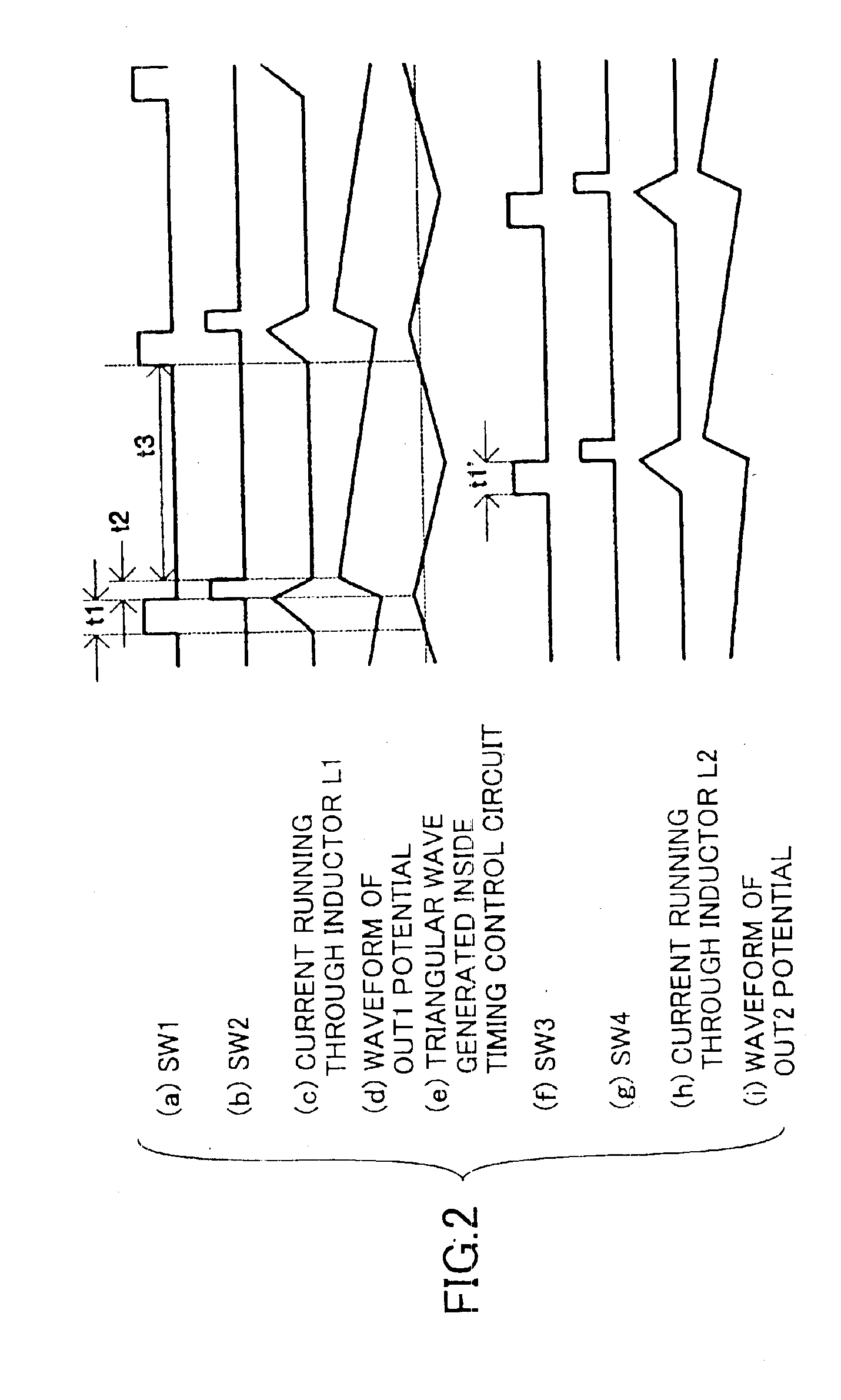

Switching regulator having two or more outputs

InactiveUS6900620B2Reduce excessive consumptionLow costApparatus without intermediate ac conversionElectric variable regulationInductorCapacitor

A switching regulator circuit includes an inductor, a first condenser which provides a potential stored therein as a first output of the switching regulator circuit, a second condenser which provides a potential stored therein as a second output of the switching regulator circuit, and a switch set including a plurality of switches, the switch set establishing a first path, a second path, and a third path, the first path supplying energy from a DC power supply to the inductor for accumulation of the energy therein, the second path supplying the energy accumulated in the inductor to the first condenser, and the third path supplying the energy accumulated in the inductor to the second condenser.

Owner:SOCIONEXT INC

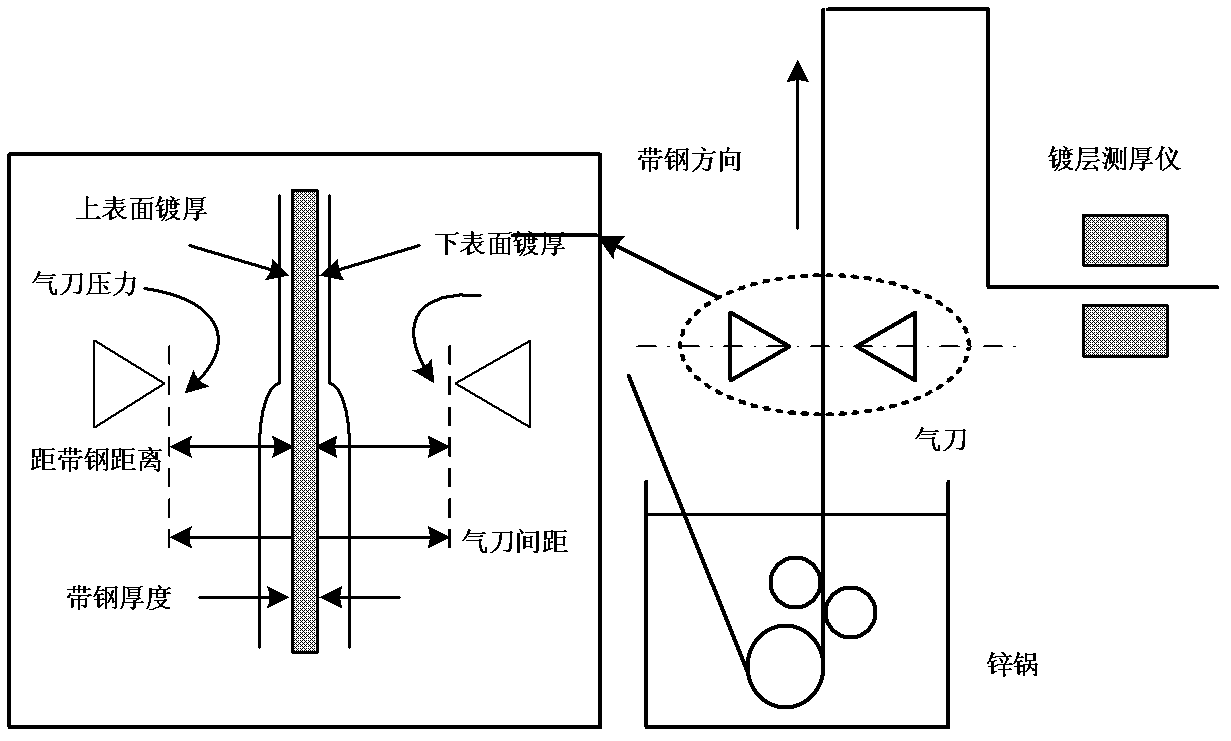

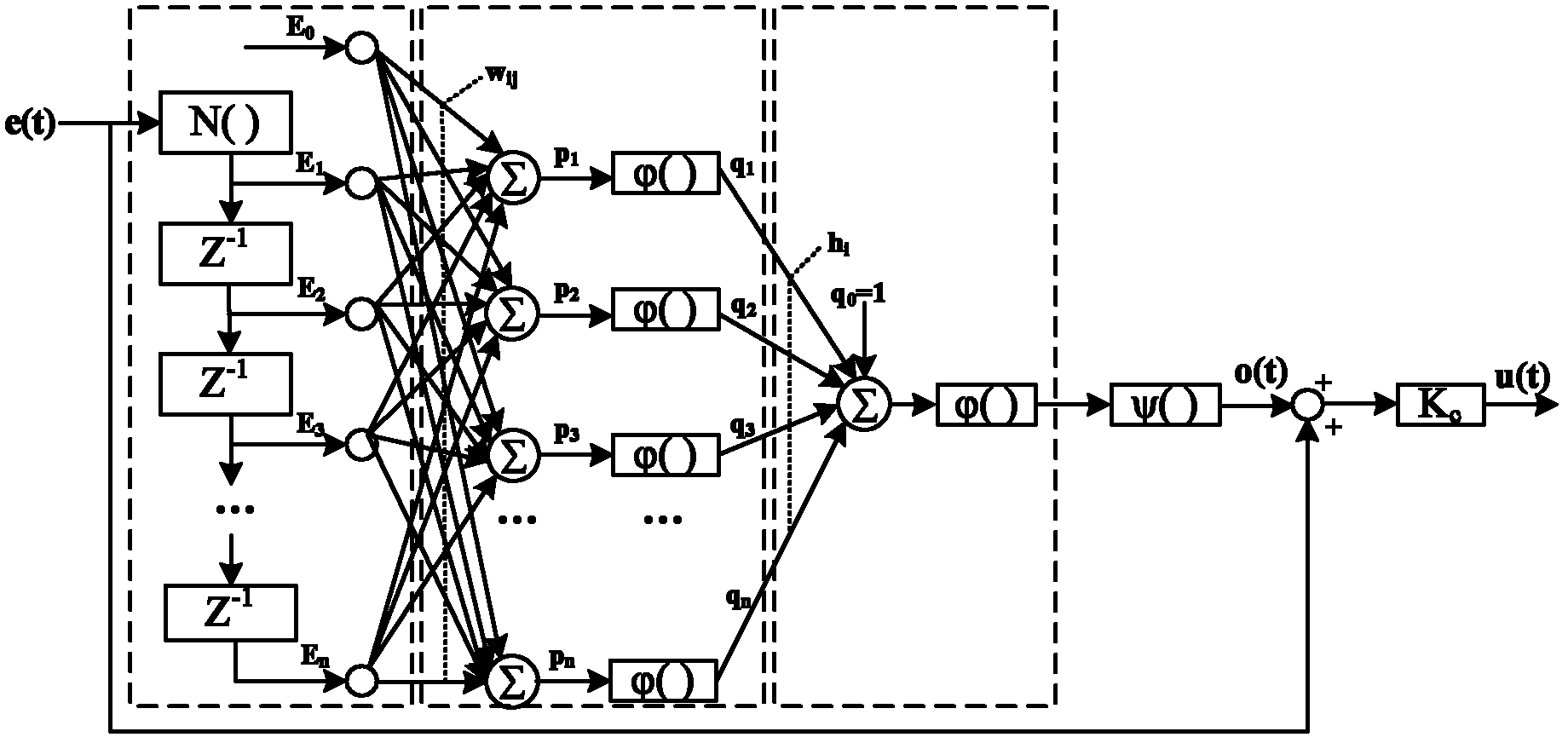

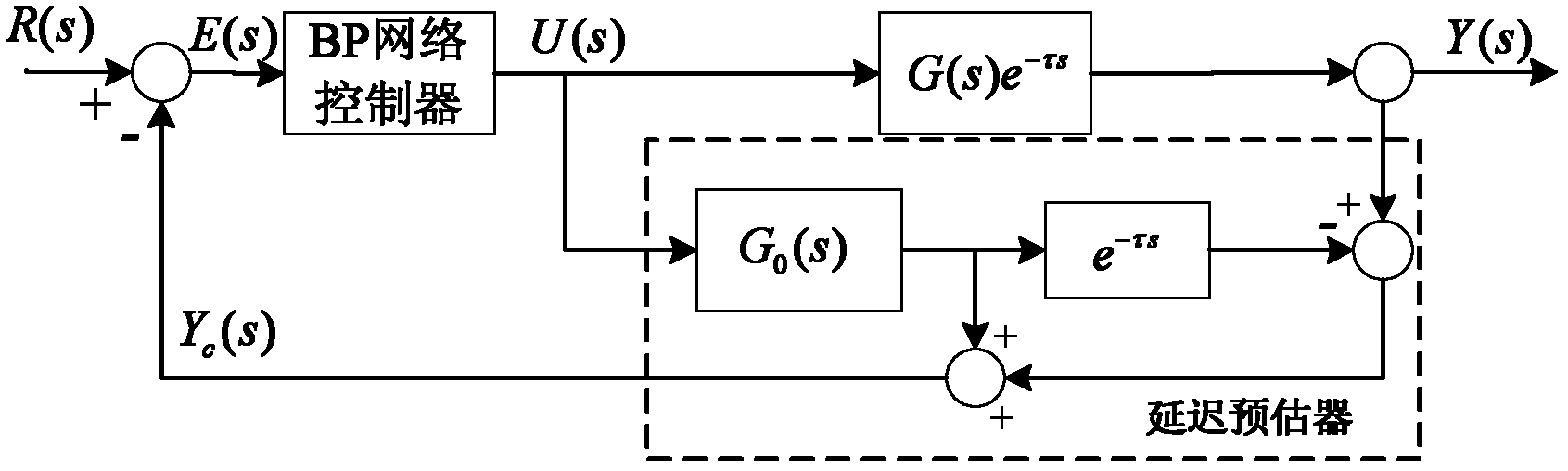

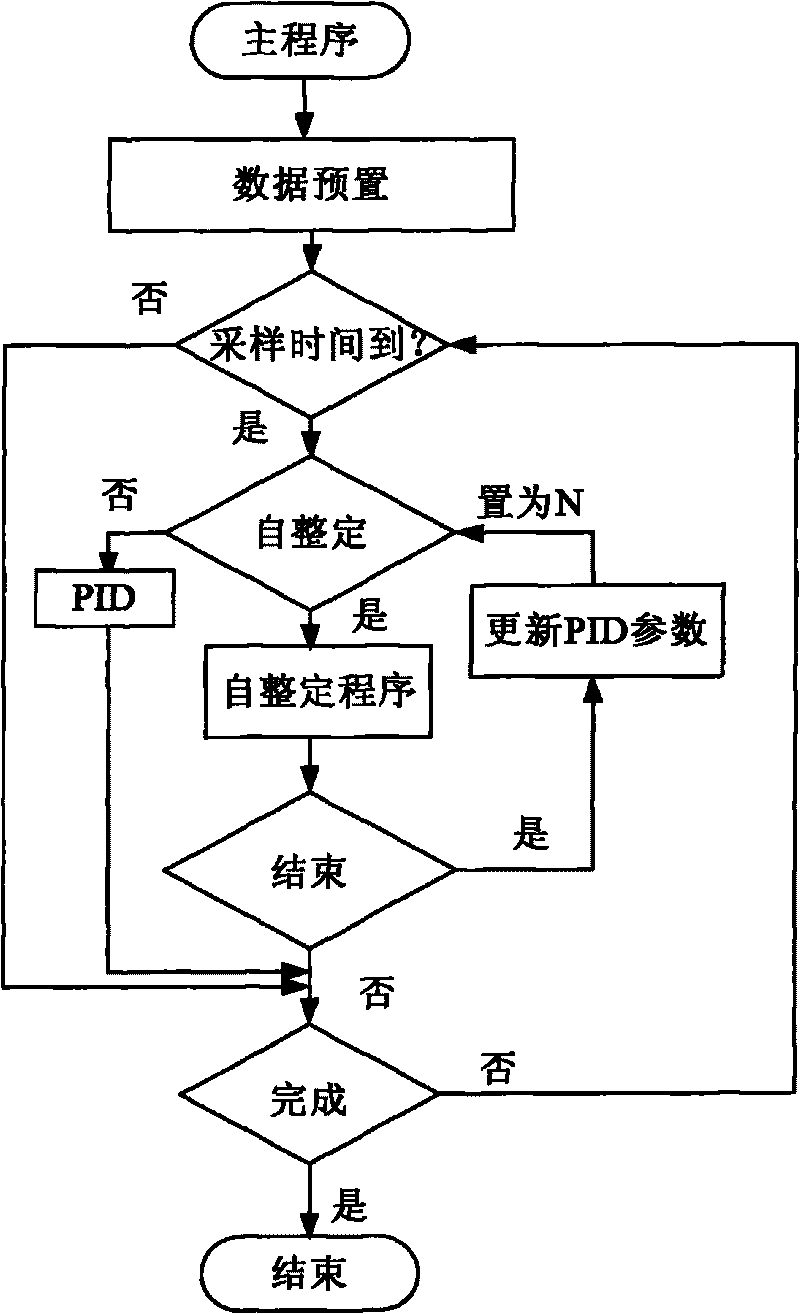

An automatic control method for zinc layer thickness in a continuous hot galvanizing zinc line

ActiveCN103205665AReduce excessive consumptionImprove surface qualityHot-dipping/immersion processesAutomatic controlClosed loop

The invention provides an automatic control method for zinc layer thickness in a continuous hot galvanizing zinc line. According to the method, a self-adaptive controller of a BP neural network structure and a delay estimation strategy are adopted to realize closed-loop precise control of a plating layer; a sampling thickness deviation of the plating layer is adopted as inputs of a self-adaptive control model of the BP neural network structure; and finally reasonable outputs are generated through data treatment of two groups of weighting factors [Delta]wij(n) and [Delta]hj(n) in the self-adaptive control model, so that air-knife pressure can be adjusted in time; and finally, the deviation between a preset value of the thickness of the plating layer and an actual sampling value becomes smaller and smaller. A learning algorithm of the weighting factors refreshes the weighting factors continuously by the smallest deviation between the preset value of the thickness of the plating layer and a measured value as a principle, and finally the results of self-adaptive adjustment of the two groups of the weighting factors make deviation between the preset value of the thickness of the plating layer and the actual sampling value tend to zero. The method can greatly reduce excessive consumption of zinc, improves surface quality of the hot galvanizing zinc plating layer, and increases added value of products.

Owner:ANGANG STEEL CO LTD

The processing technology of fragrant tempeh

InactiveCN102273597AProduction process fermentation time is shortenedShorten fermentation timeFood preparationFlavorFermentation

The invention relates to a processing technique of concentrated fragrant fermented black bean, belonging to the technical field of condiment. The technological flow is as follows: preparing purple whins, screening, washing, soaking, draining, cooking, cooling, moulding, cleaning moulded purple whins, soaking with decoction of raw materials and auxiliary material, fermenting, airing, braising and steaming with a steamer, drying by the air, and obtaining the finished product (dry fermented black bean). Compared with the prior art, the processing technique provided by the invention has the advantages that production period is shortened and yield is improved; and materials are developed and improved, thus product has good flavour and taste and has health care effect.

Owner:彭虎德

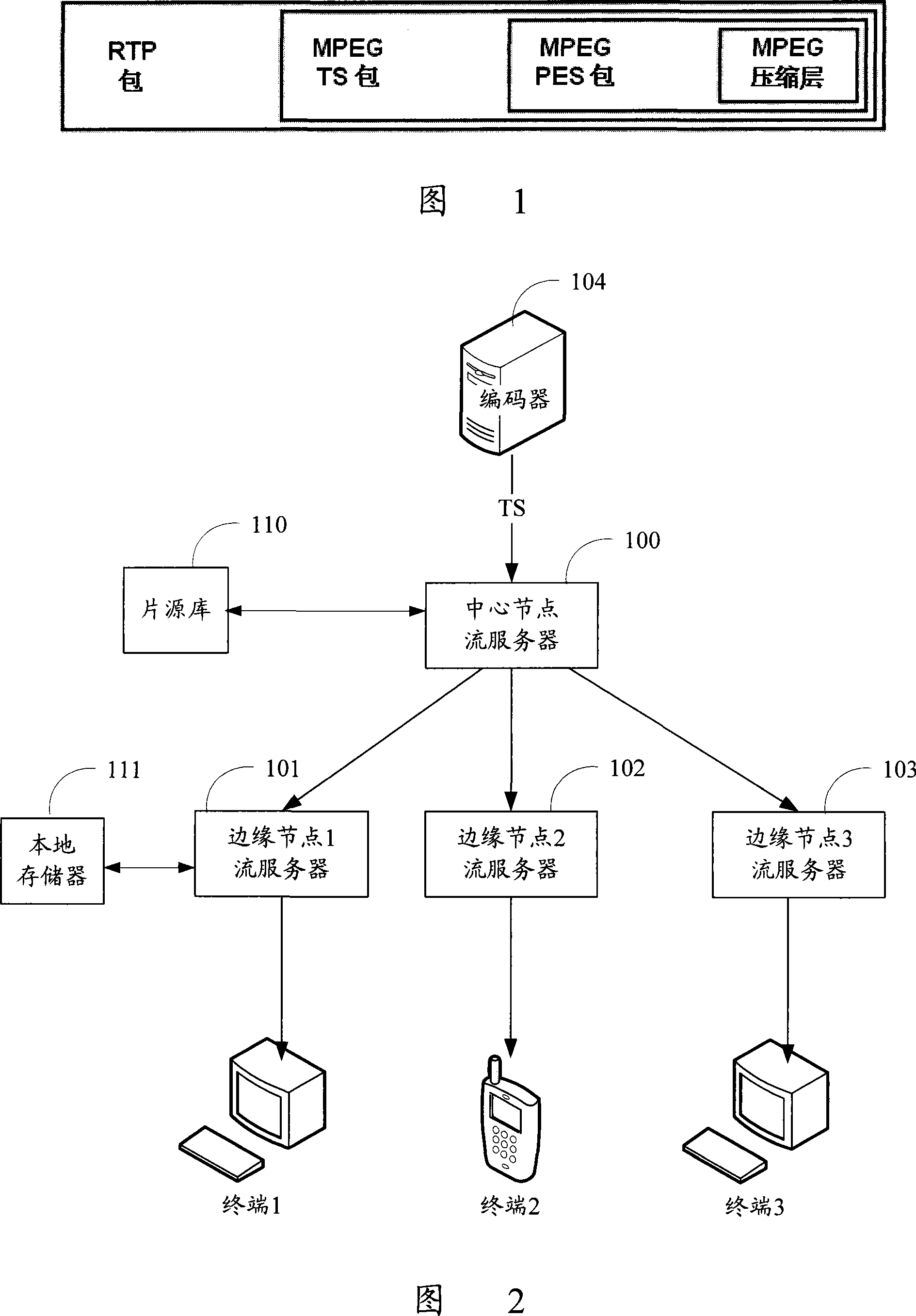

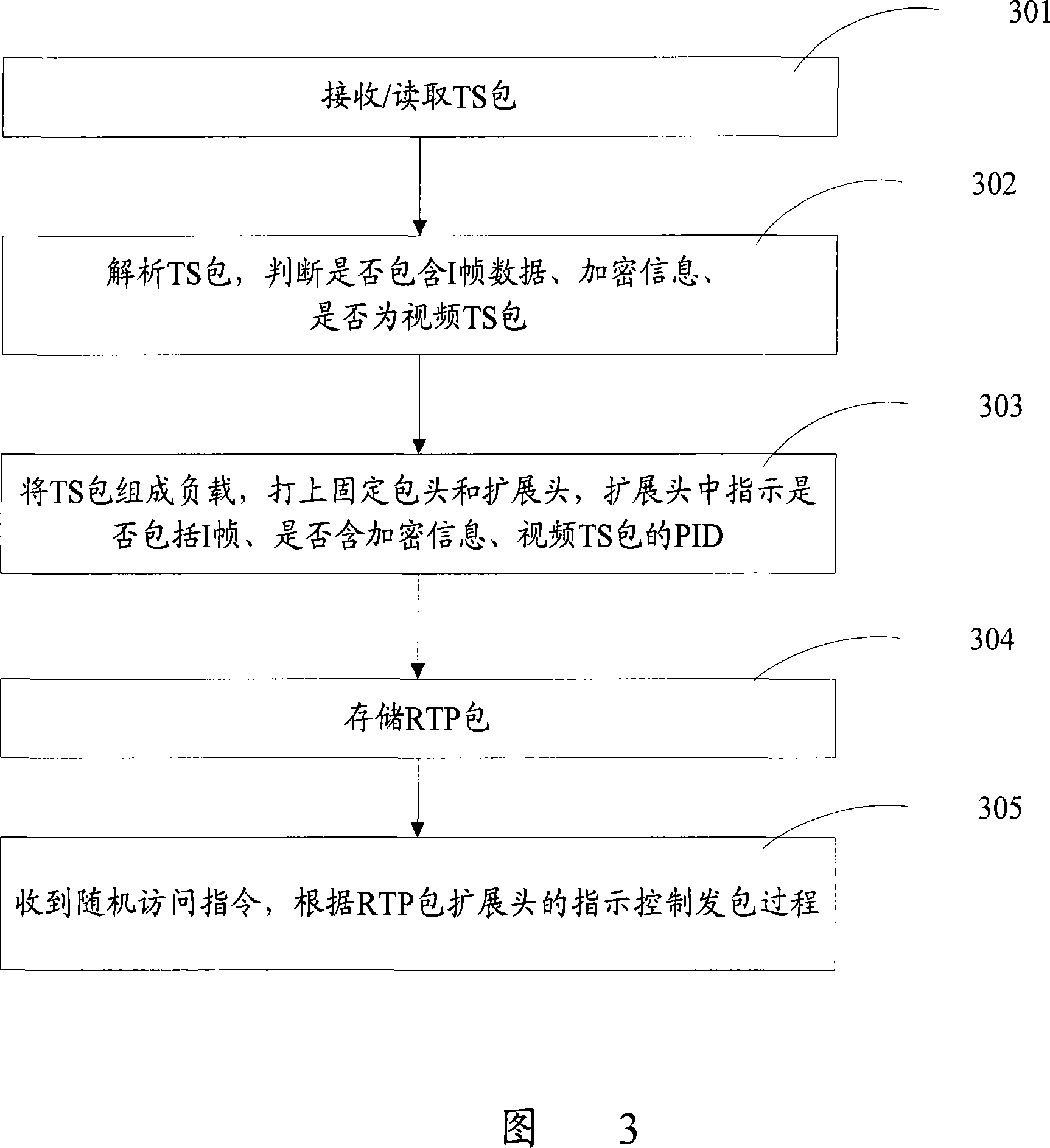

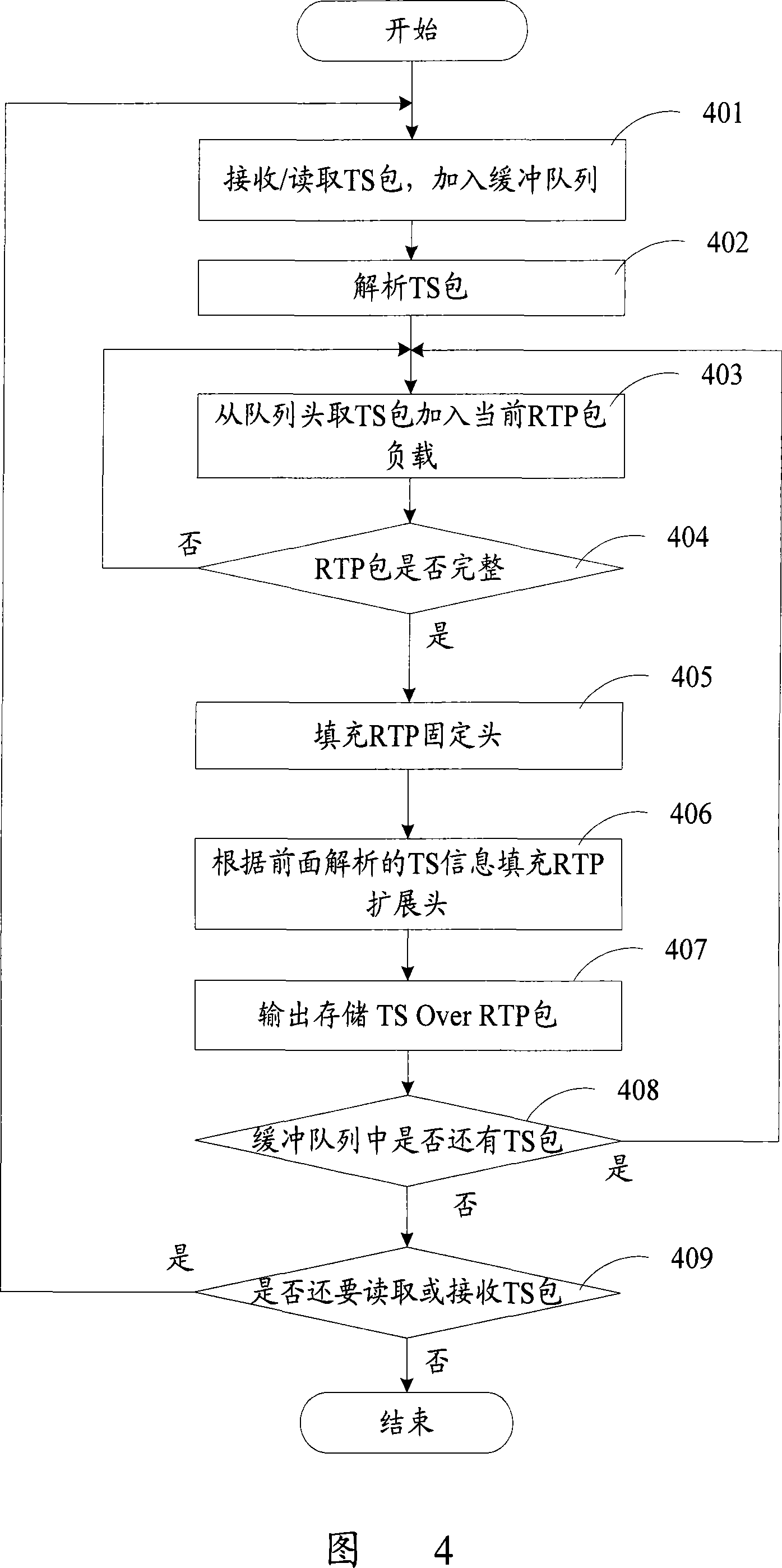

Transmission processing method for MPEG conveying stream in video-on-demand service

InactiveCN101222616AHigh speedReduce consumptionPulse modulation television signal transmissionTwo-way working systemsMPEG transport streamReal-time Transport Protocol

The invention discloses a transport processing method of MPEG transport stream TS in a request service, which is applicable to a stream server. The method comprises that: A. analyzing and inquiring whether key frame data is included in a coded TS packet or not; B. combining the TS packets into loading data of a real-time transport protocol RTP packet which is packed through filling with RTP headers comprising an extension header with indication information which is used to indicate that whether the key frame data is included in the RTP packet; C. storing the RTP packet; D. searching a RTP packet required by a random access after receiving a random access command, and determining whether to send the packet or not according to the indication of the extension head. The invention can avoid using a complicated search algorithm to determine whether a media packet is a random access point or not during each random access, thereby reducing consumption for system resources, improving the efficiency of the random access, and reducing the cost.

Owner:ZTE CORP

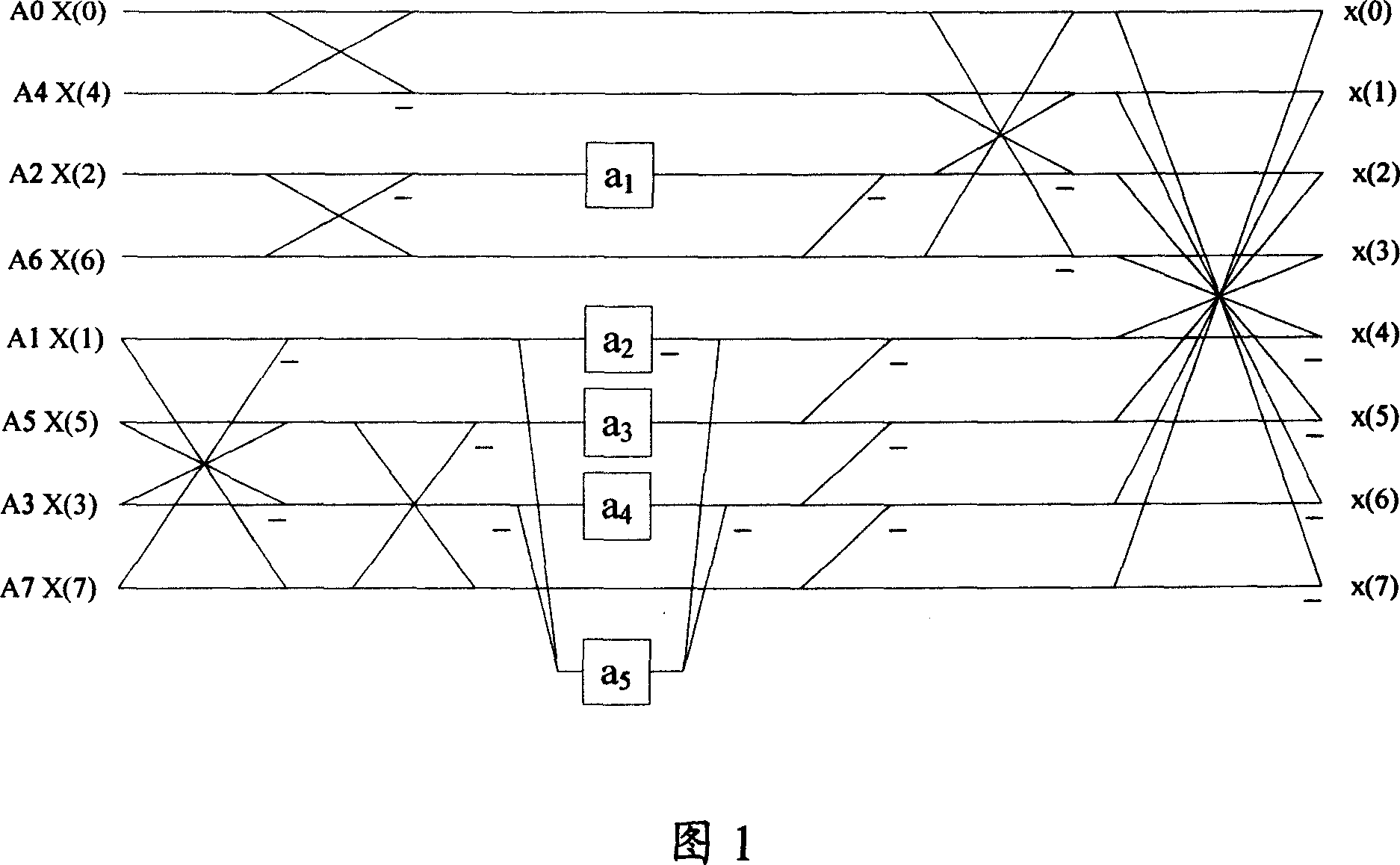

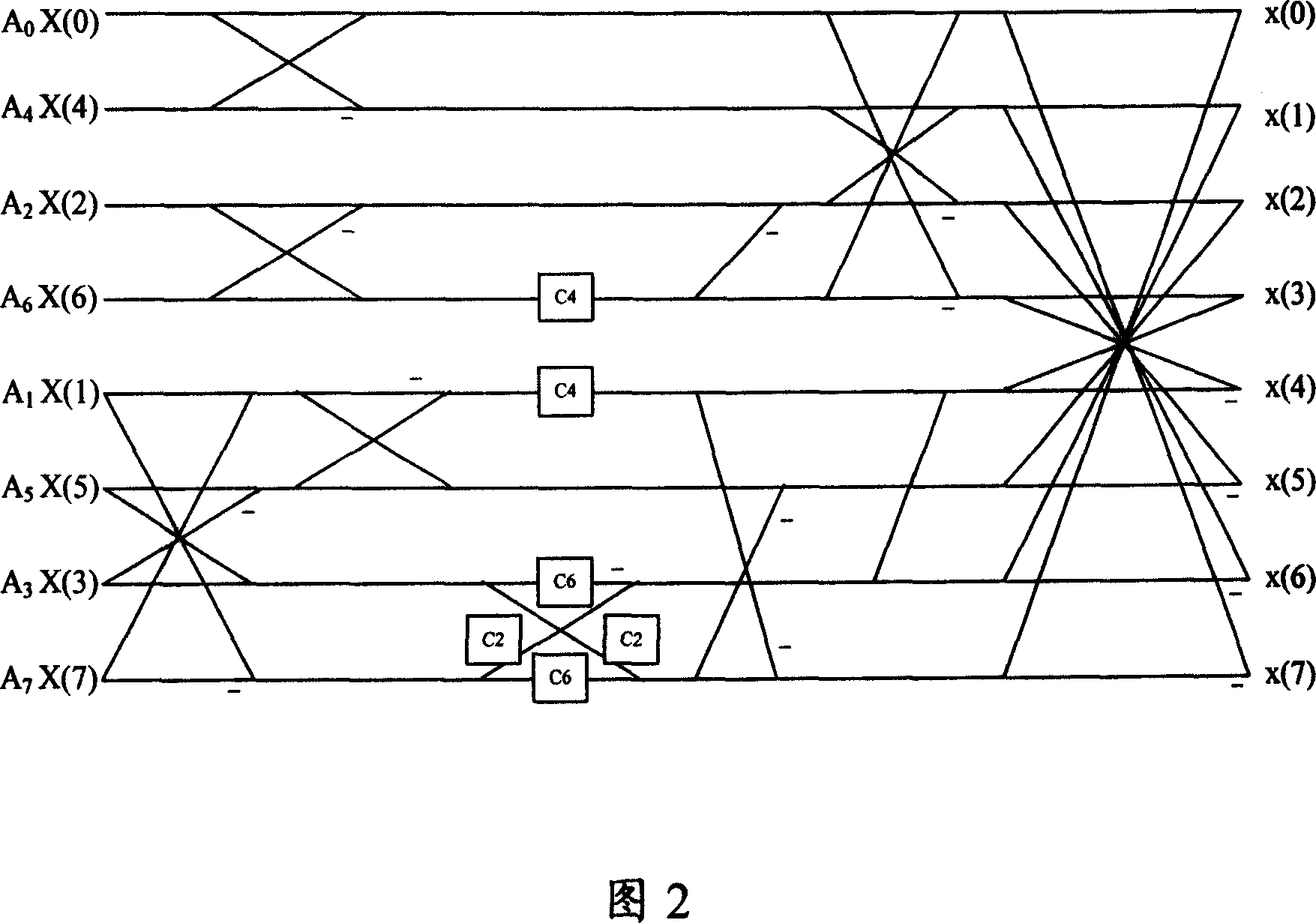

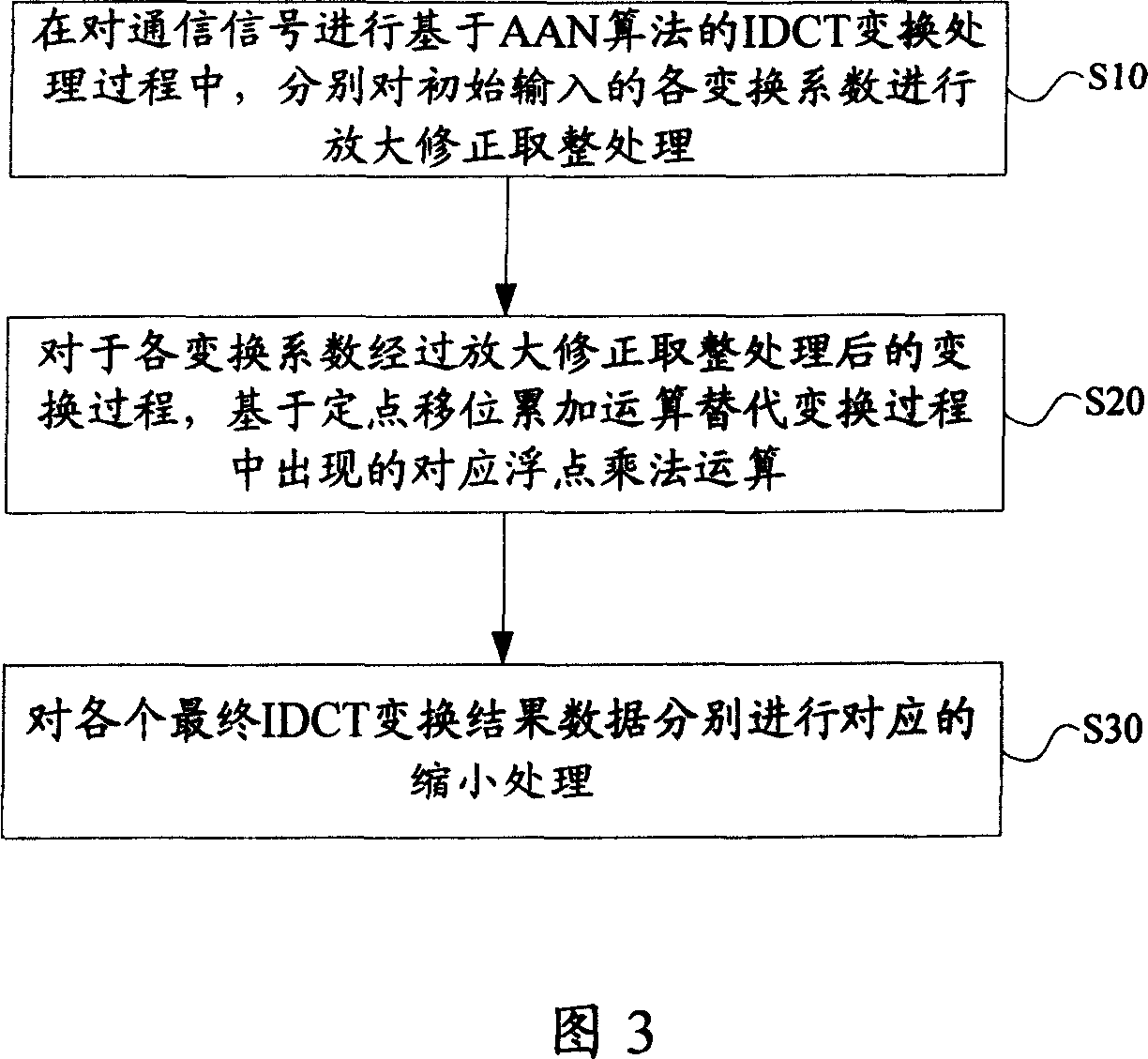

Discrete cosine inverse transformation method and its device

InactiveCN101047849AGuarantee the accuracy of the transformation resultSpeed up transform processingPulse modulation television signal transmissionDigital video signal modificationFloating point multiplicationComputer science

This invention discloses a scattered cosine inverse transformation method including: carrying out amplifying, correcting and rounding process to the transformed coefficients input initially in the process of scattered cosine inverse transformation to digital signals based on AAN algorithm to substitute corresponded floating-point multiplication operation appearing in the transforming process based on a fixed-point shift accumulation operation and carrying out corresponding reduction process to the final inverse transformation results. This invention also discloses a device.

Owner:HUAWEI TECH CO LTD

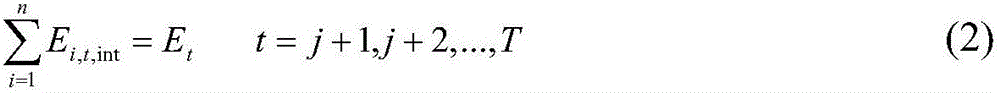

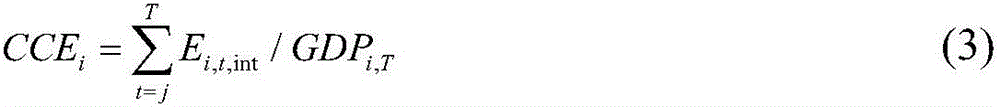

Method for constructing power generation carbon emission quota distribution model under inter-provincial carbon trading mechanism

InactiveCN105975770AEmission reductionReduce excessive consumptionSpecial data processing applicationsInformaticsElectricityCarbon emission trading

The invention relates to a method for constructing a power generation carbon emission quota distribution model under an inter-provincial carbon trading mechanism, belonging to the technical field of low-carbon electricity of power systems. The method comprises the following steps of: constructing a first-stage distribution model for inter-provincial quota distribution, wherein the first-stage distribution model is composed of two links including an initial distribution model and a re-adjusted model for the result of the initial distribution model, and, by taking the result of the first-stage distribution model as the boundary condition, constructing a second-stage distribution model for distributing carbon emission quota distribution results of various provinces obtained by the first-stage distribution model among various power plants in the province; and, according to the two-stage distribution models, obtaining an inter-provincial distribution scheme for power generation carbon emission quota distribution and the power generation carbon emission quota of various power plants in the province under the inter-provincial carbon trading mechanism. According to the method disclosed by the invention, on the basis of the existing carbon trading experimental unit in the province, power generation carbon emission quota distribution under the inter-provincial carbon emission trading mechanism is researched in combination with characteristics of the power industry; due to the method disclosed by the invention, low-carbon development can be realized; excessive consumption of fossil energy can be reduced; and the purpose of effectively reducing carbon emission can be achieved.

Owner:POWER GRID TECH RES CENT CHINA SOUTHERN POWER GRID +2

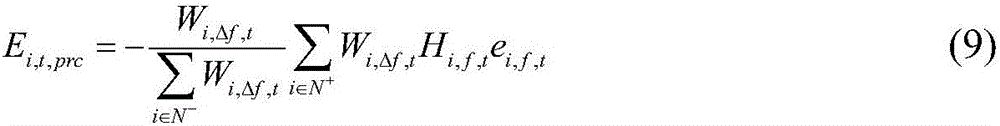

Relocation method and device of terminal location, terminal and storage medium

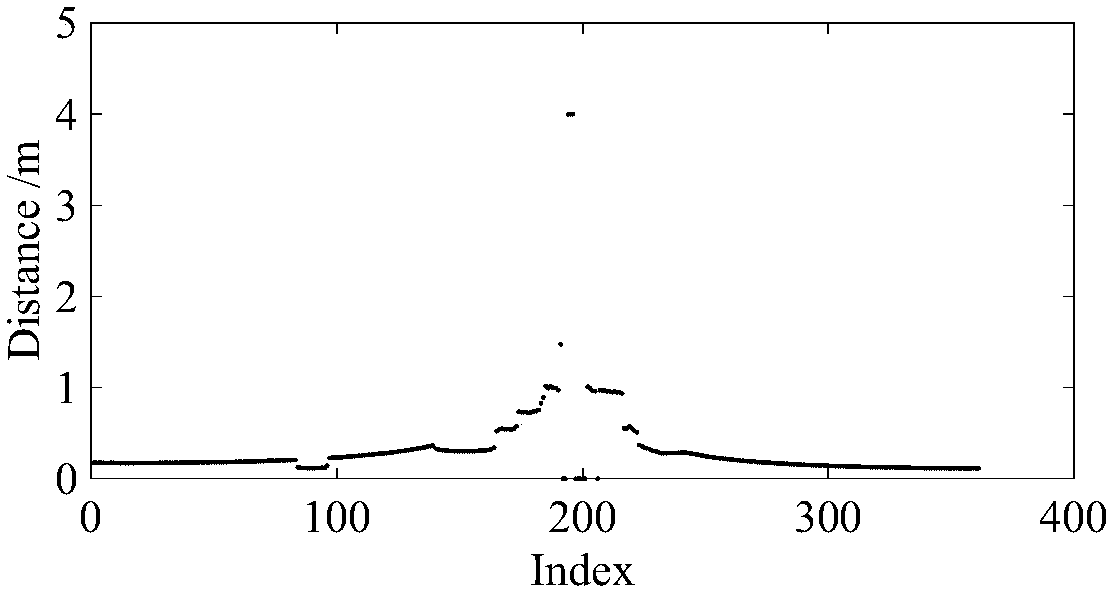

ActiveCN107561549AGuaranteed accuracyReduce excessive consumptionCharacter and pattern recognitionElectromagnetic wave reradiationCurrent timeLidar data

The invention discloses a relocation method and device of a terminal location, a terminal and a storage medium. The method comprises: laser radar data currently captured by a laser data in a terminalare obtained; according to the laser radar data and a preset laser radar classifier, a target classification tag corresponding to the laser radar data is obtained; according to the target classification tag, an initial candidate position set of the terminal in a global map is determined; and on the basis of the initial candidate position set and a set relocation strategy, a re-localized target position of the terminal in the global map at a current time is determined. With the method disclosed by the invention, effective selection of the relocation candidate area is realized, so that the highaccuracy of the relocation result during relocation of the terminal in the relocation candidate area is guaranteed; excessive consumption of computing resources and time is reduced and the limitationcaused by manual determination of a feature point is avoided. The relocation method and device can be applied to a complicated external environment.

Owner:GUANGZHOU SHIYUAN ELECTRONICS CO LTD

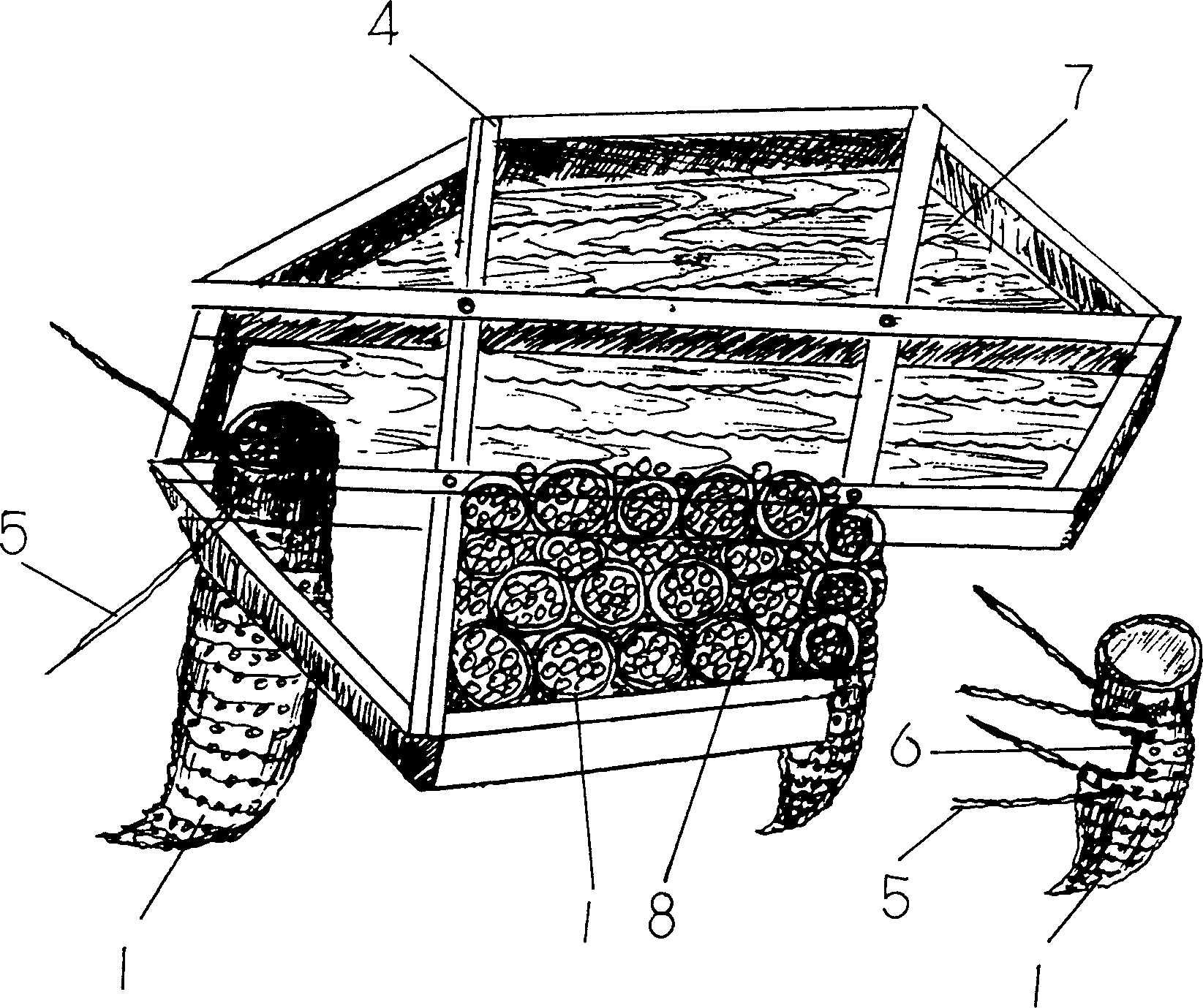

Method for processing compound oat nutritious food with liquid fermentation tricholoma matsutake mycelium polysaccharide

The invention relates to a method for processing a nutritious health food, in particular to a method for processing a compound oat nutritious food added with liquid fermentation tricholoma matsutake mycelium polysaccharide. The method comprises the following steps of: performing liquid fermentation on tricholoma matsutake to culture tricholoma matsutake mycelium; extracting tricholoma matsutake polysaccharide from the tricholoma matsutake mycelium; and combining the tricholoma matsutake polysaccharide with oats to produce the oat nutritious food. The compound oat nutritious food with the liquid fermentation tricholoma matsutake mycelium polysaccharide has the advantages of rich nutrition and low price, and ensures that common people can enjoy the daintiness, the nutrition and an anti-cancer effect of the tricholoma matsutake whle eating the oat instant product; and the method not only reduce the price of the tricholoma matsutake product, but also improves the nutrient components of the conventional oat product and combines the two aspects to provide a convenient, quick and nutritious good food for the consumers in general, and simultaneously promote the industrialized development of edible fungi, so the method can inevitably create huge economic benefit and social benefit.

Owner:冯磊

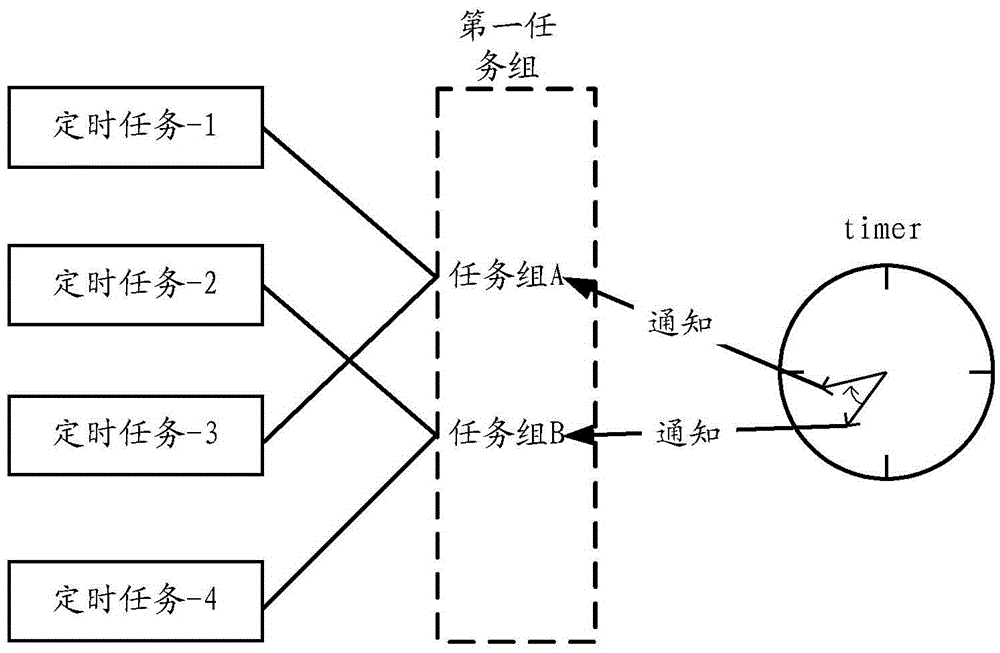

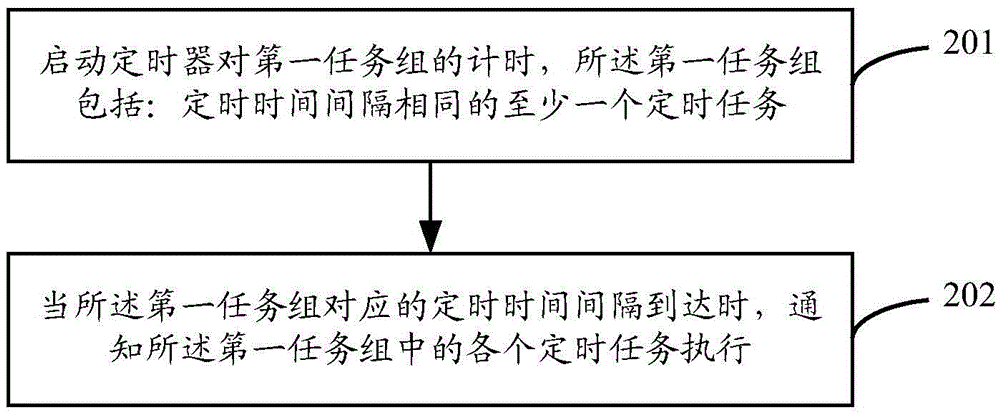

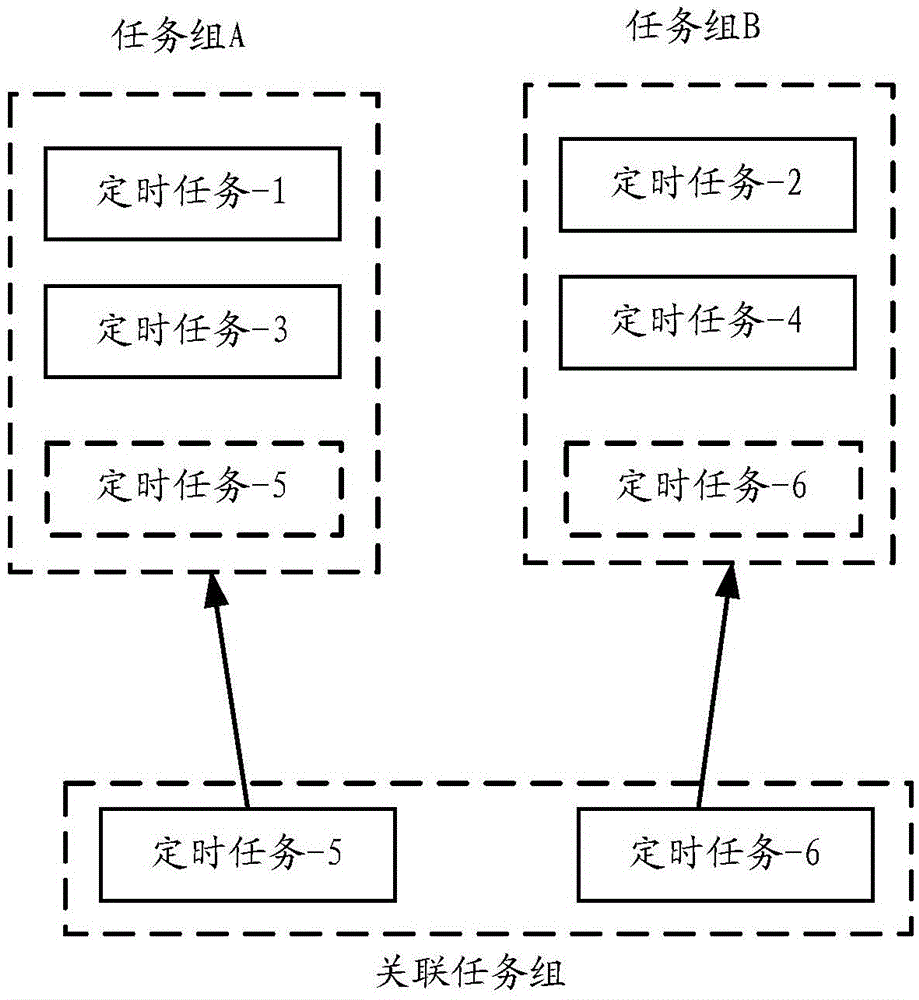

Task scheduling method and system

InactiveCN106886450AReduce excessive consumptionProgram initiation/switchingResource consumptionTimer

The invention relates to a task scheduling method and system. The method comprises the steps of starting timing of a timer to a first task group, wherein the first task group comprises at least one timing task same in timing time interval; and when the timing time interval corresponding to the first task group is up, notifying each timing task in the first task group to be executed. According to the method and the system, excessive system resource consumption of relatively numerous timing tasks is reduced.

Owner:ALIBABA GRP HLDG LTD

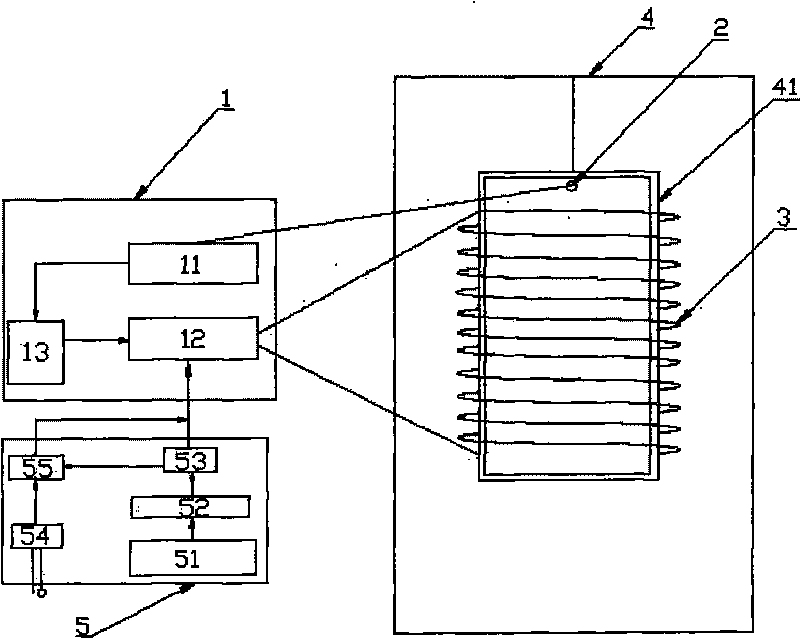

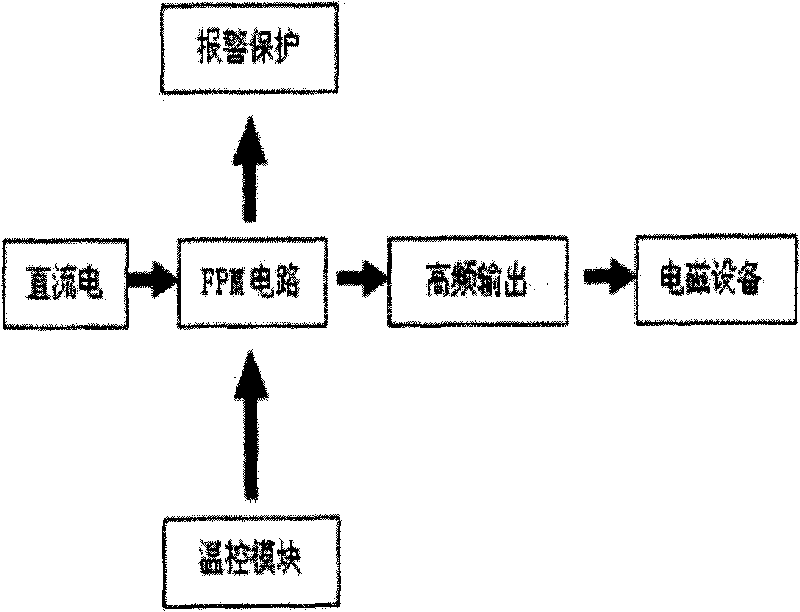

Solar electromagnetic boiler

InactiveCN101709904AReduce excessive consumptionEliminate potential safety hazardsWater heatersElectromagnetic inductionTemperature measurement

The invention discloses a solar electromagnetic boiler, comprising a boiler body, an electromagnetic heating temperature control system and a solar power supply device; the boiler body comprises a heat receiver, the electromagnetic heating temperature control system comprises an electromagnetic heating temperature control device, an electromagnetic coil and a temperature measuring sensor; the solar power supply device comprises a solar cell panel and a storage cell. The solar cell panel utilizes solar to supply power for the storage cell; direct current is output to an alternative current high-frequency output module, is converted to alternative current high-frequency current under the control of a microprogrammed control unit (MCU) and is output to the electromagnetic coil; and the heat receiver is heated through electromagnetic induction. A temperature detecting module is connected with the temperature measuring sensor in the heat receiver to obtain the value of the temperature and then feeds back the temperature value to the MCU, and the MCU regulates the size of the high-frequency current or control on and off according to the received temperature data. The solar electromagnetic boiler can fully utilize solar to carry out electromagnetic heating, realizes automatic temperature measurement and temperature control, and has the characteristics of energy saving, environment protection and high safety factor.

Owner:青岛福润德自动化技术有限公司

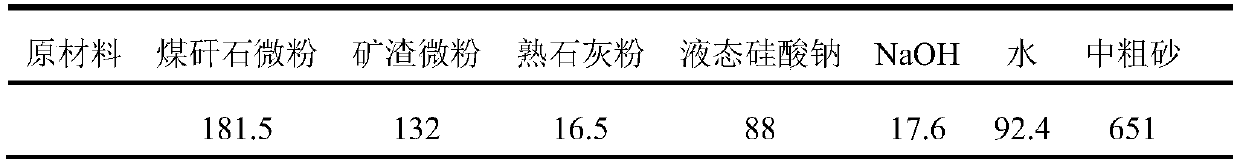

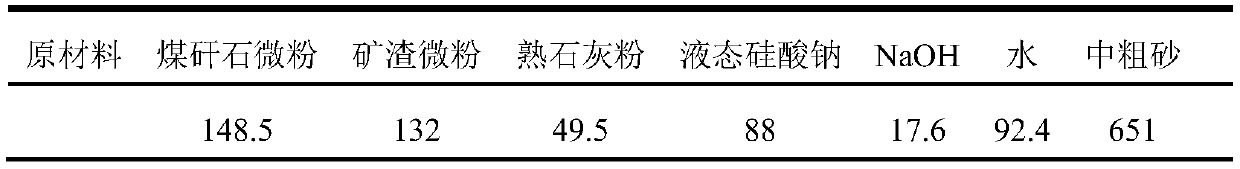

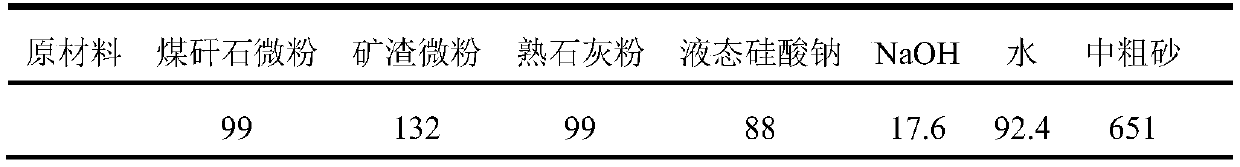

Preparation method of quick setting and rapid hardening gangue alkali-activated rapid repairing material

The invention relates to a preparation method of a quick setting and rapid hardening gangue alkali-activated rapid repairing material. The content of active calcium is increased by doping an appropriate amount of hydrated lime powder, the process of a polymerization reaction and formation of polymer products are promoted, the setting time of the coal gangue alkali-activated material is obviously shortened, the early strength is greatly improved, and finally application of the coal gangue alkali-activated material in serving as a rapid repairing material in engineering. The coal gangue alkali-activated rapid repairing material can adjust the setting time by itself, the excellent cohesiveness, early strength and high strength characteristics are achieved, and the material is very suitable for serving as the rapid repairing material for use. The coal gangue alkali-activated rapid repairing material can replace a cement repairing material for use, not only can the environmental pollution problem caused by large accumulation of waste coal gaugue can be eliminated, but also excessive dependence on cement can be relieved, and excessive consumption of non-renewable resources is reduced, and the method has great significance to countries such as China serious in energy shortage and environmental pollution.

Owner:ANHUI UNIV OF SCI & TECH

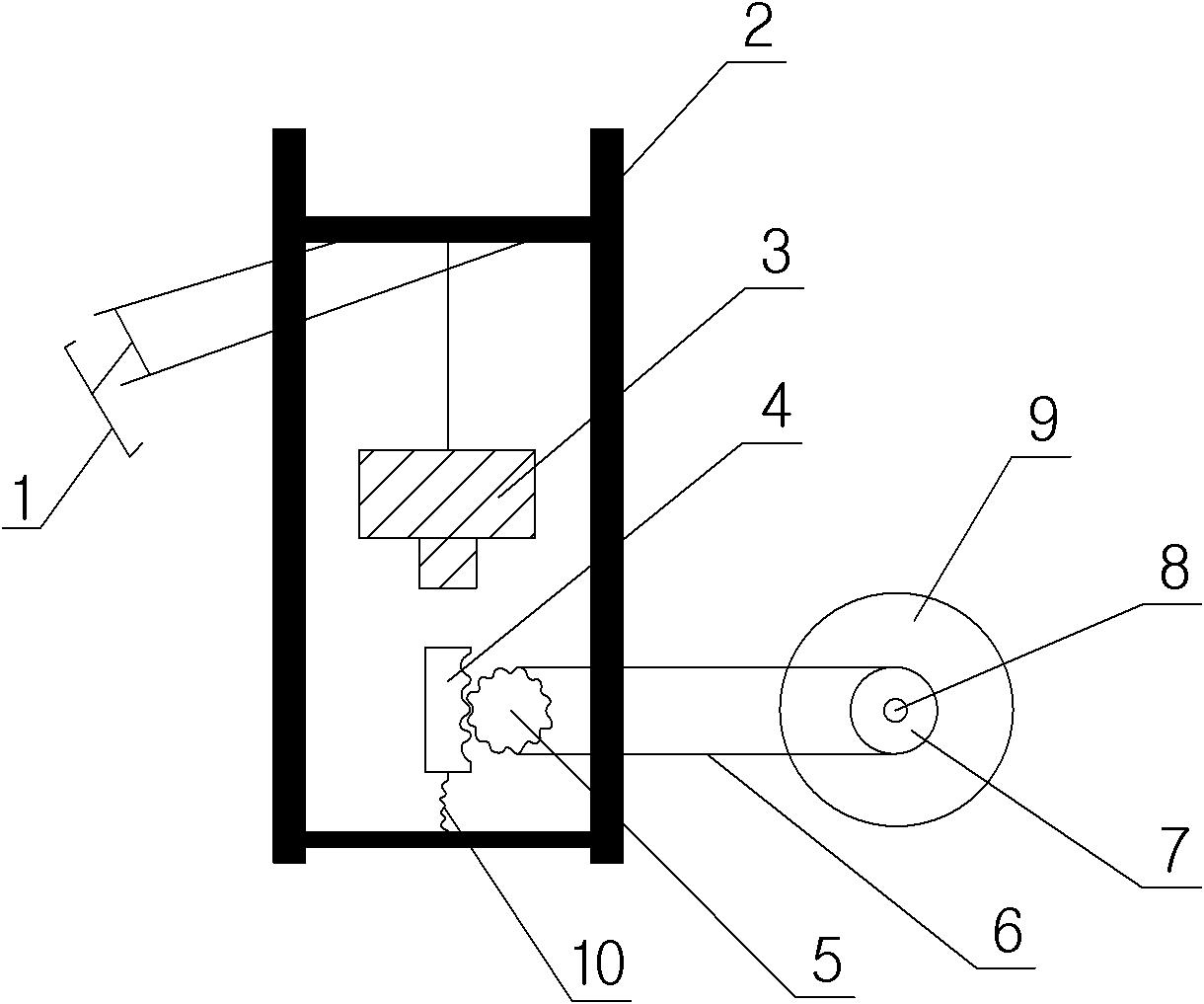

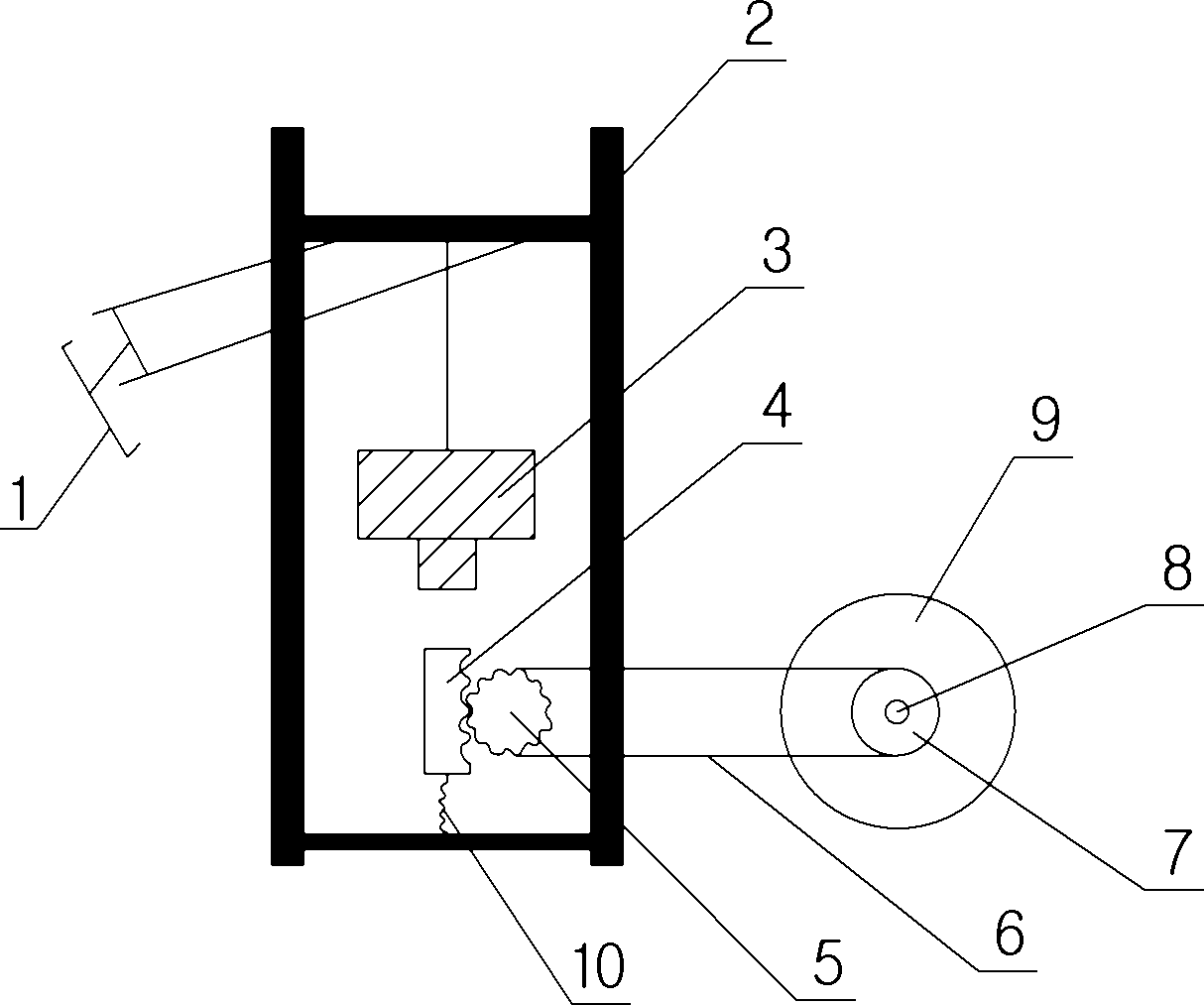

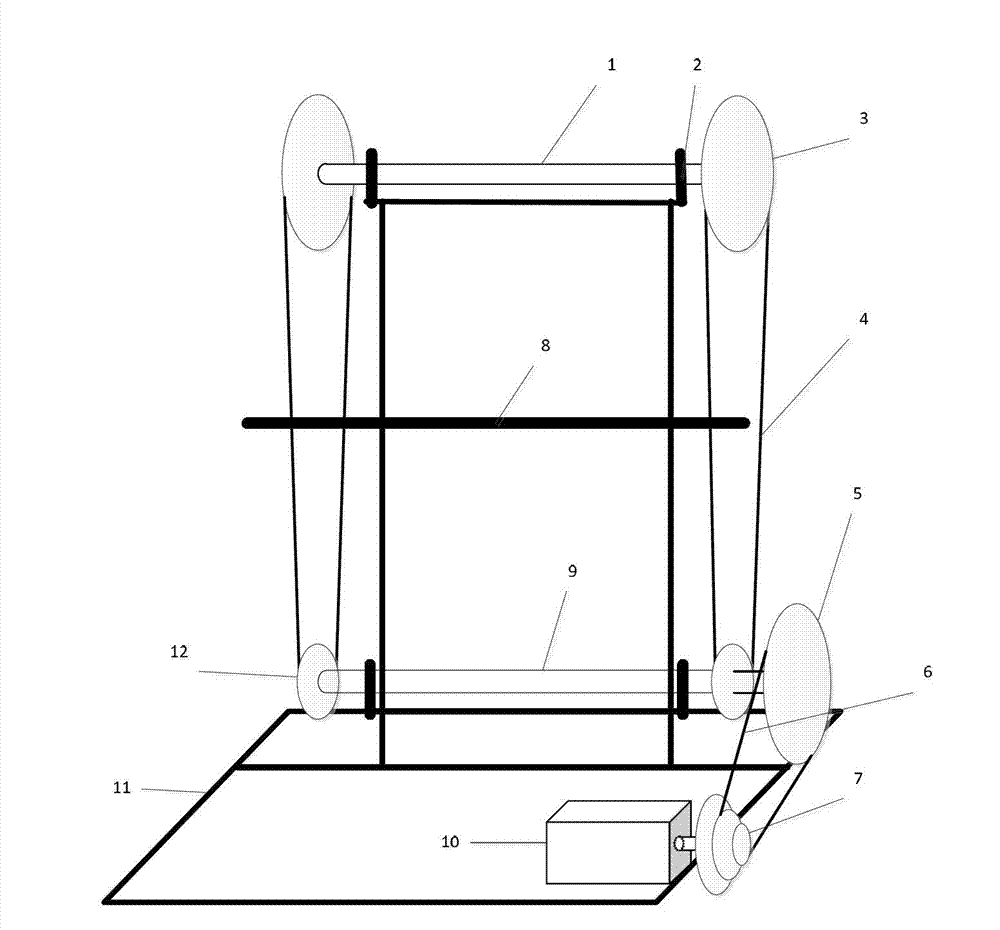

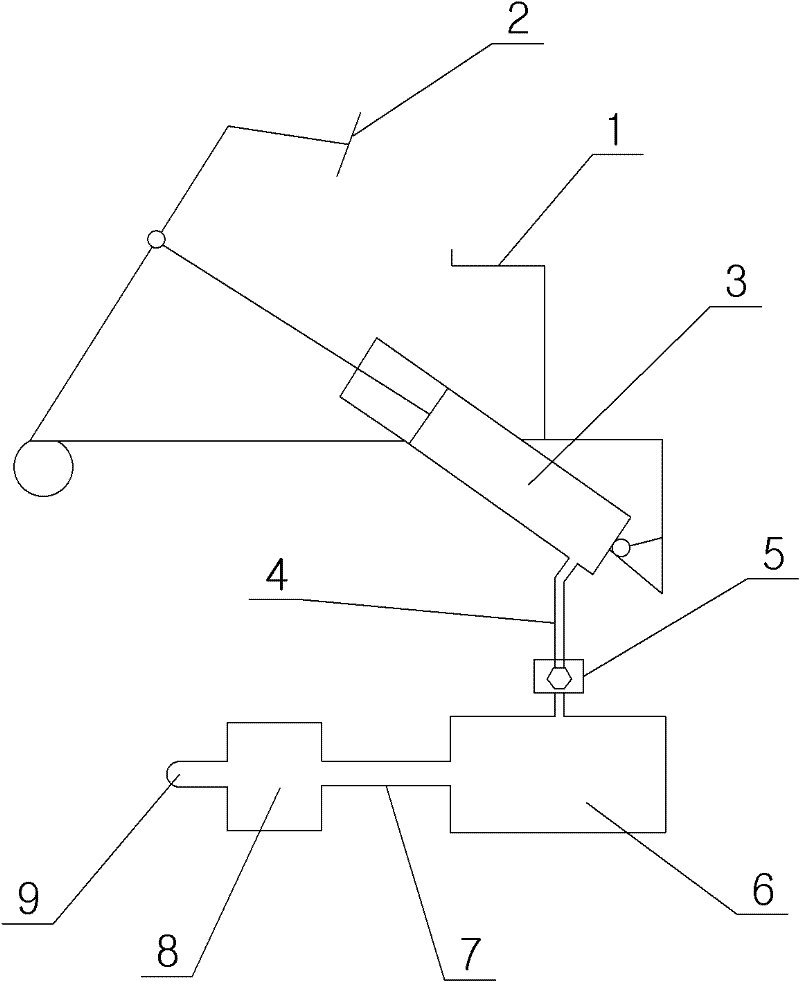

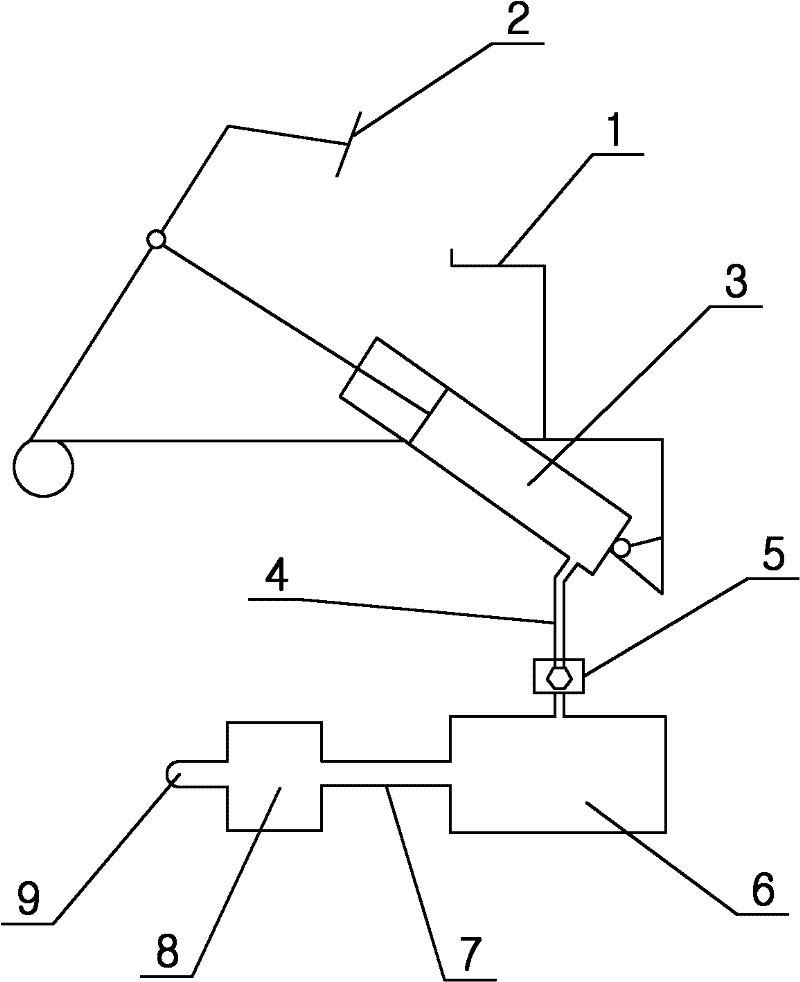

Strength training instrument power generation device

InactiveCN102486166AAlleviate excessive consumptionEnvironmental protection and energy savingFrom muscle energyMachines/enginesElectricityEngineering

The invention discloses a strength training instrument power generation device which comprises a gear, a rack, a flywheel and a generator. Both the rack and the gear are arranged inside a strength training instrument bracket. The rack is positioned below a strength training instrument counter weight. The bottom of the rack is connected with the bottom of the strength training instrument bracket through a pressure spring. The gear is meshed with the rack. The gear is connected with the flywheel arranged outside the strength training instrument bracket. The generator is connected with the flywheel and the generator can be driven by the flywheel to generate electricity. An inertial wheel is also arranged on the flywheel. According to the invention, physical energy consumed when people exercise is converted into electric energy; and the strength training instrument power generation device has a simple structure, is convenient to use and is convenient to popularize and use.

Owner:XIAN DAYU PHOTOELECTRIC TECH

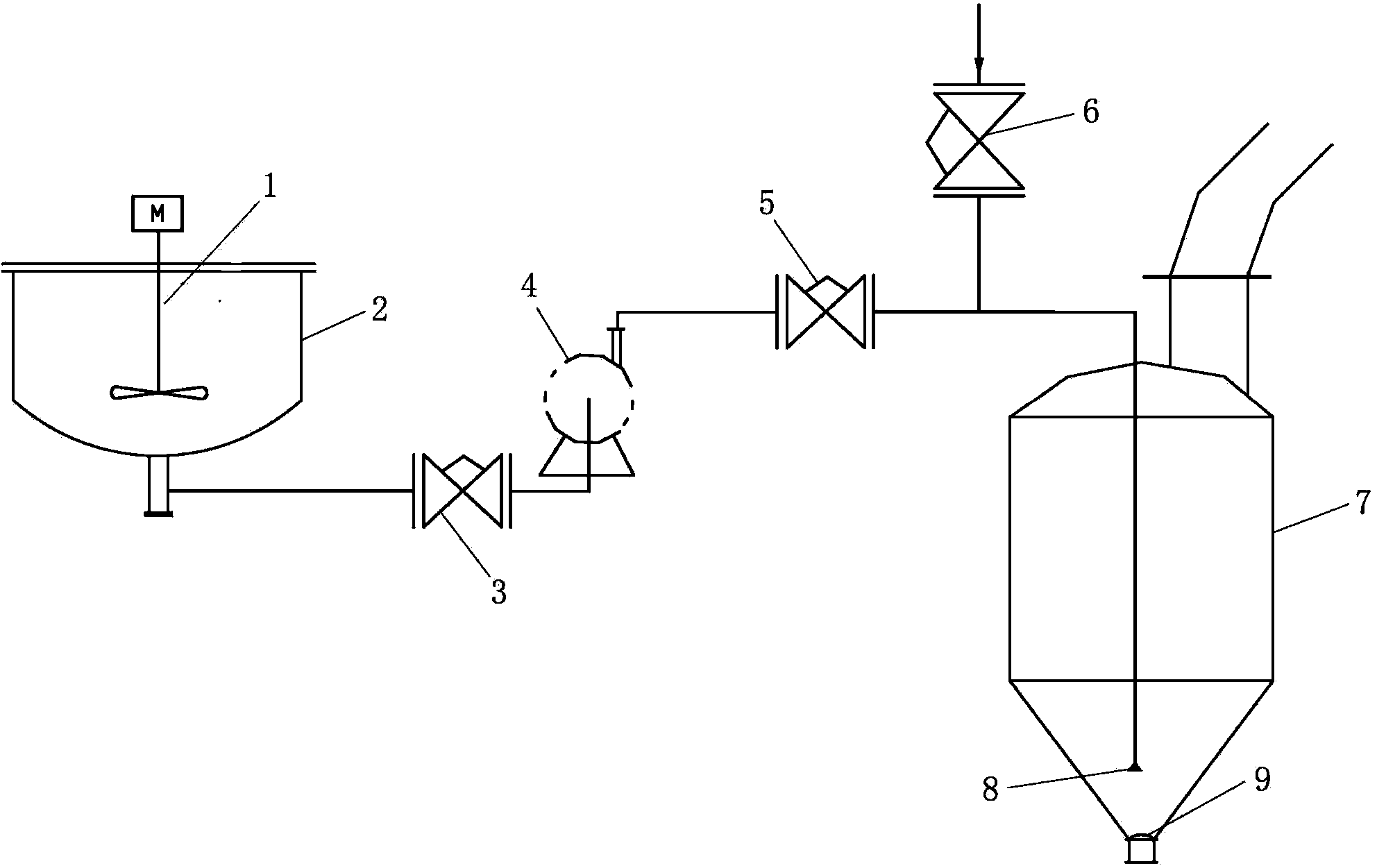

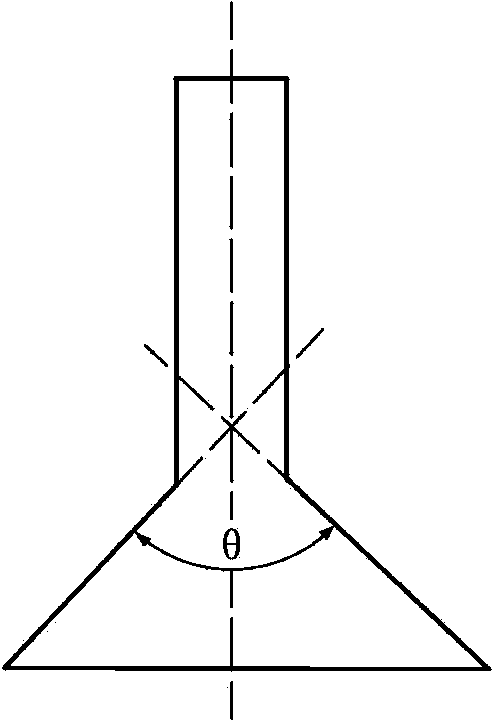

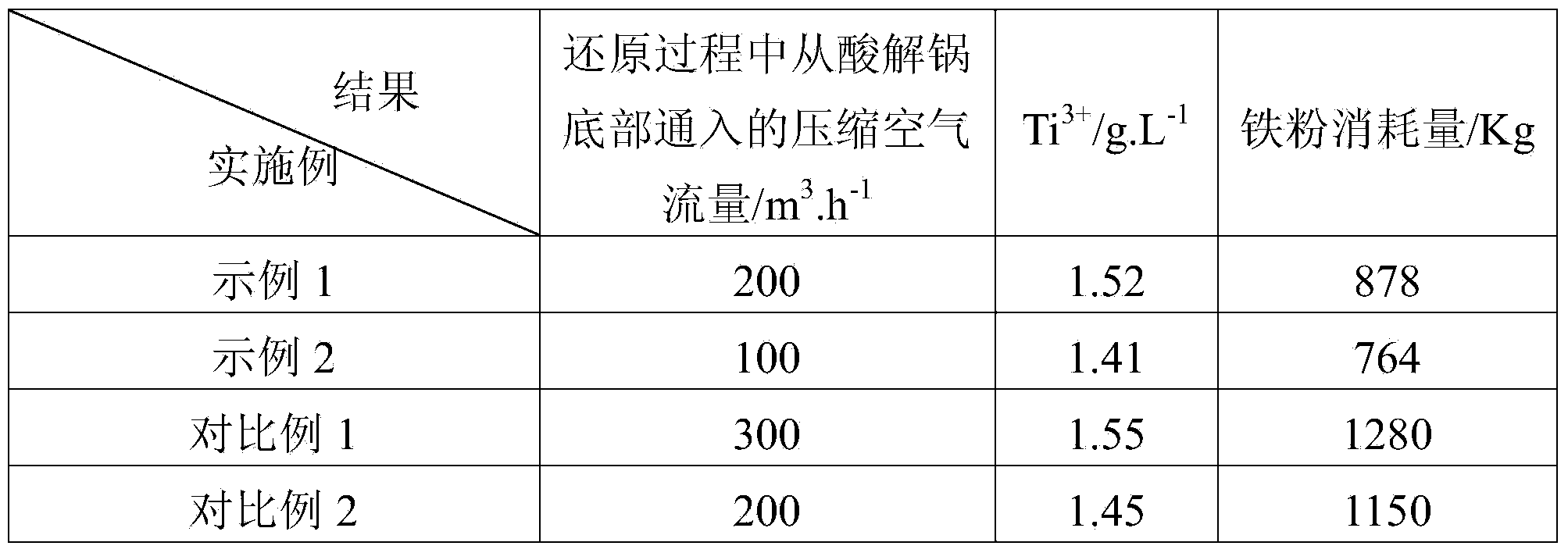

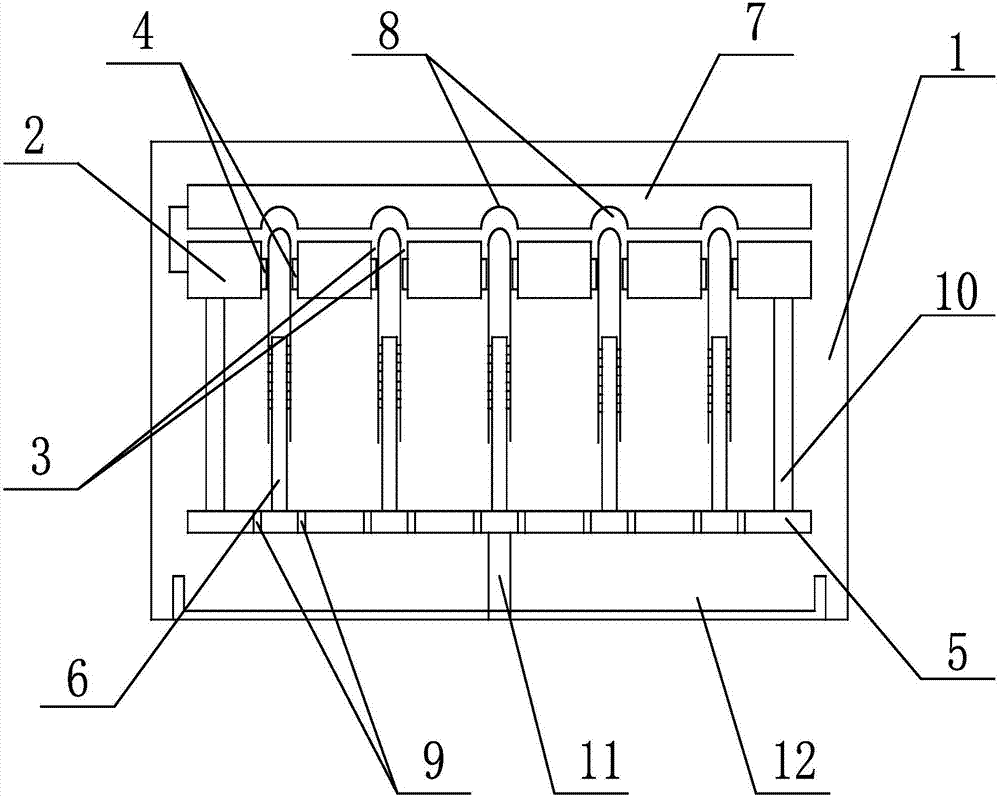

Process for producing titanium dioxide through sulfuric acid method as well as titanyl sulfate solution reduction device and method

ActiveCN103641164AReduce excessive consumptionReduce the amount of oxygenTitanium dioxideSulfateProcess engineering

The invention provides a process for producing titanium dioxide through a sulfuric acid method as well as a titanyl sulfate solution reduction device and method. The device comprises a compressed air supply pipe, a first valve, a second valve, a compressed air valve and a mixing kettle, a delivery pump and a reactor which are connected in order through a pipeline, the mixing kettle is used for preparing an iron reducing agent and water into suspension by mixing, the first valve is arranged on a first part between the mixing kettle and the delivery pump, the second valve is arranged on a second part between the delivery pump and the reactor; the compressed air supply pipe is connected with a third part between the second part of the pipeline and the reactor so as to supply the compressed air to the reactor through the pipeline; the compressed air valve is arranged on the compressed air supply pipe, the reactor is filled with a to-be-reduced titanyl sulfate solution, and the bottom thereof is provided with a compressed air distribution plate; and one end of the pipeline connected with the reactor extends to the bottom of the reactor and is higher than the compressed air distribution plate and below the liquid level of the titanyl sulfate solution.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD +1

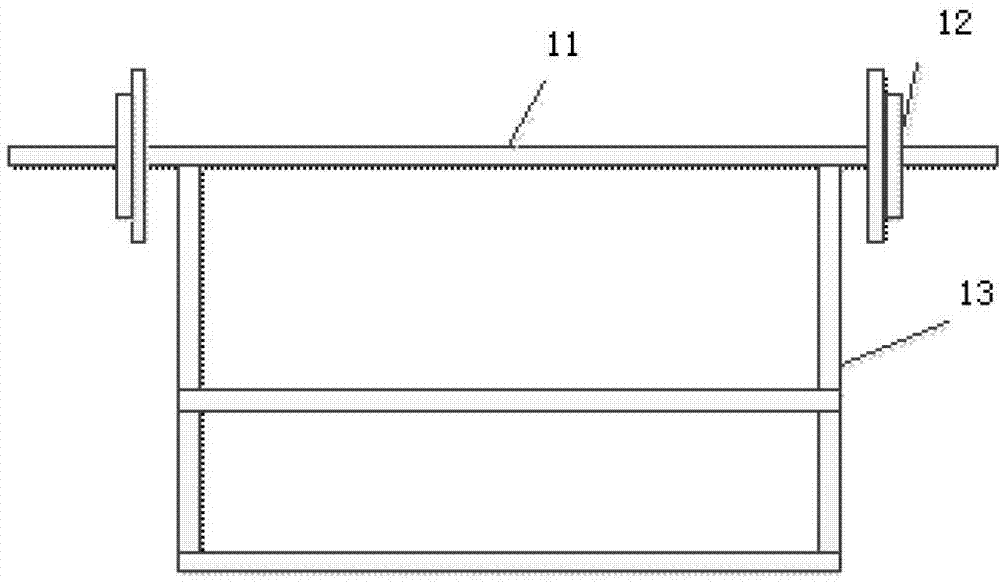

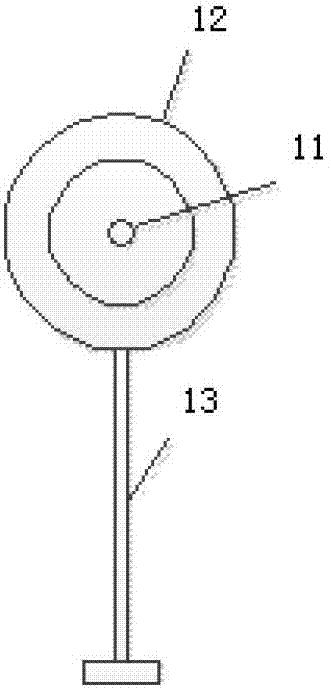

Power generation device for bench press trainer

InactiveCN103195673AReduce weight requirementsLower quality requirementsDumb-bellsFrom muscle energyBall bearingBench pressing

The invention relates to a power generation device for a bench press trainer and belongs to the technical field of power generation devices. The power generation device comprises transmission cranksets, a variable-speed crankset, transmission chains, a variable-speed chain, spindles and the like. The transmission cranksets comprise a large transmission crankset and a small transmission crankset and is driven by the transmission chains to form a transmission mechanism. A pushing rod is fixed on the transmission chains on two sides of a support, the spindles are supported by ball bearings and divided into an upper spindle and a lower spindle which are disposed above and below the support respectively, the variable-speed crankset is fixed at the tail end of the lower spindle, a tower flywheel is fixed at the shaft end of a power generator, the variable-speed crankset and the tower flywheel are connected through the variable-speed chain, and the power generator is fixed on the support. By means of the power generation device, the purpose of body building during exercise is achieved, the strength of the bench press training can be adjusted by adjusting the wheel disc radius of the tower flywheel connected into the variable-speed chain, and electric energy can be generated for users. The power generation device is novel and simple in structure, convenient to use, low in production cost and convenient to popularize and apply.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Bamboo tea table, desk, stool and its manufacturing method

InactiveCN1768647APromote sustained high yieldPromote stable productionWood working apparatusServing tablesEngineeringDesk

Owner:徐战

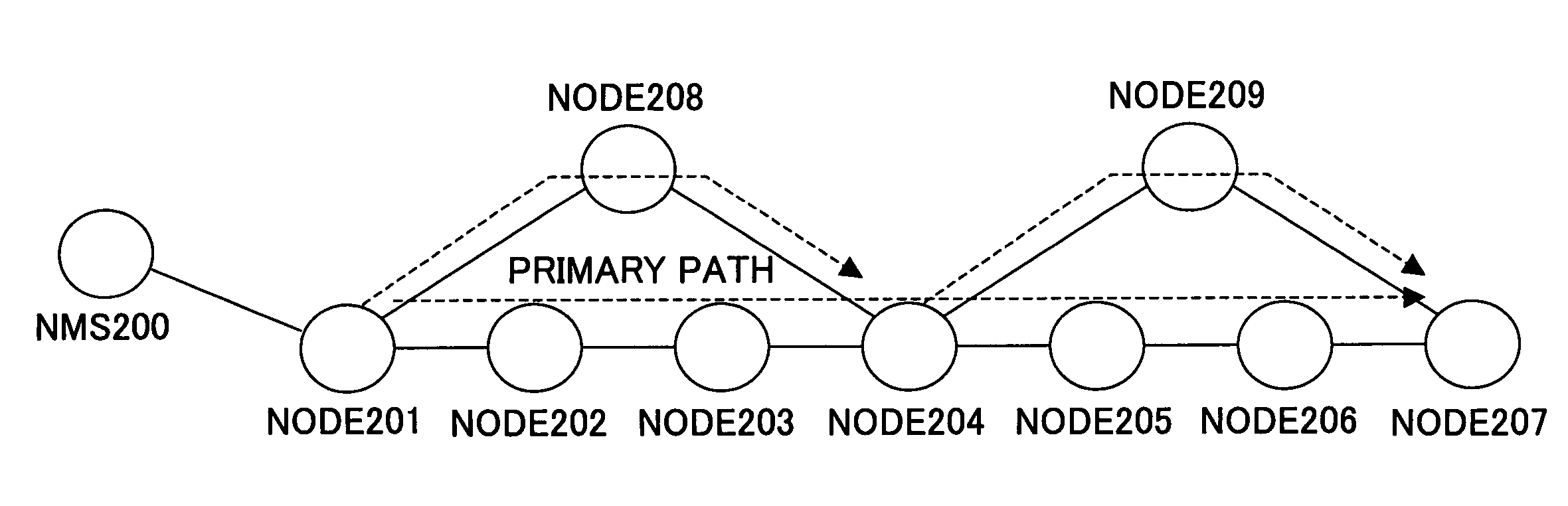

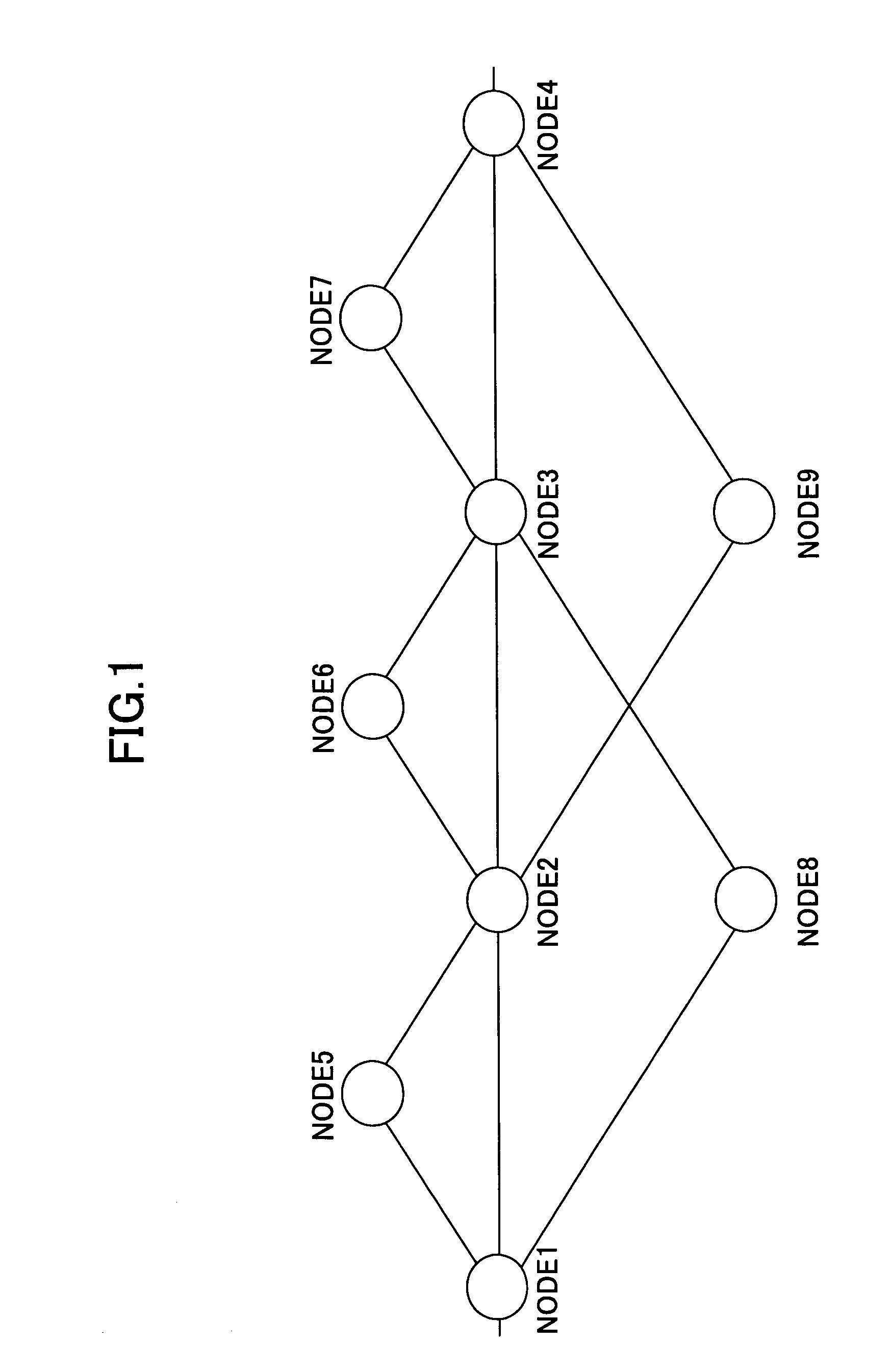

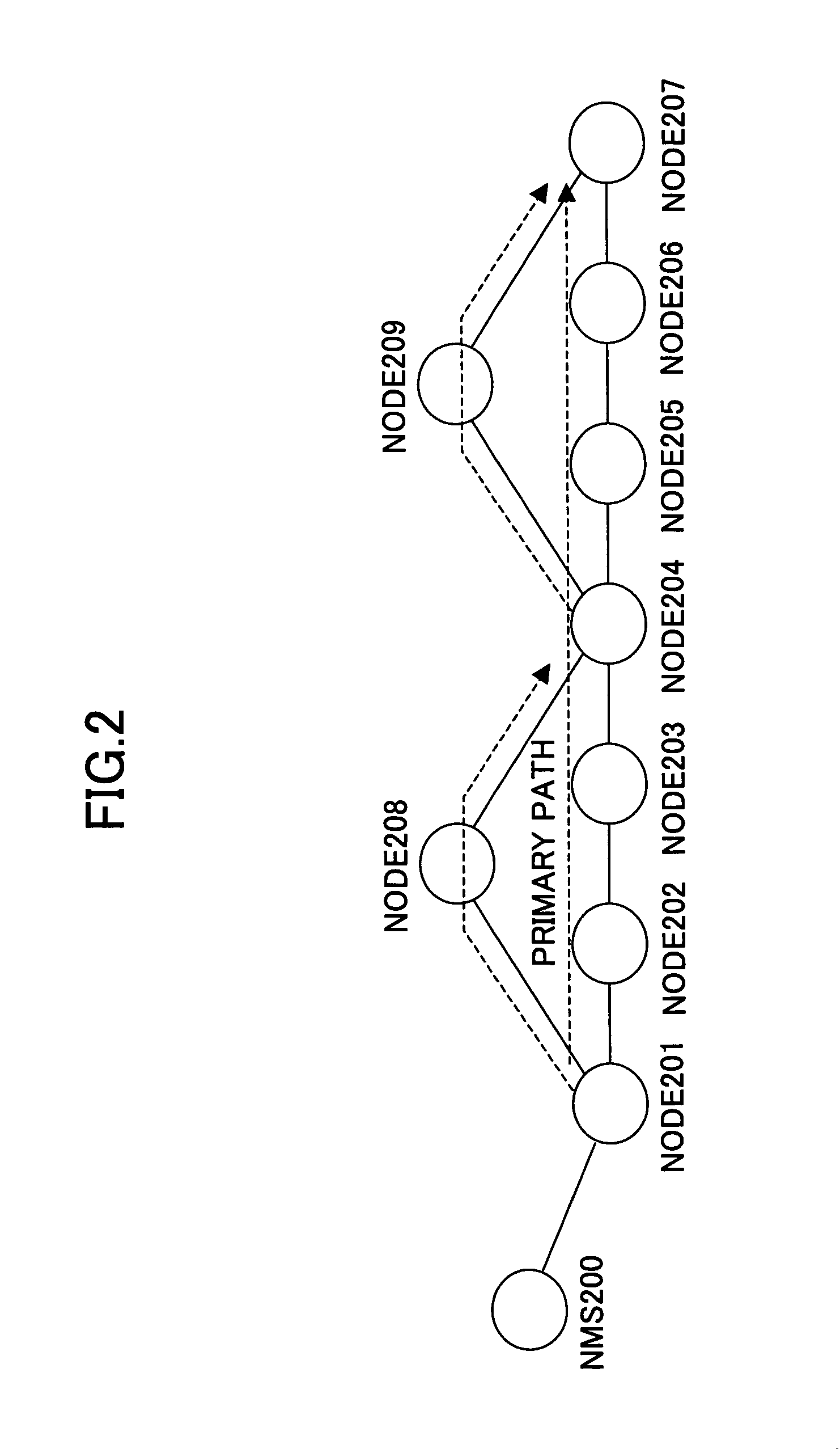

Method and apparatus for setting up backup path

InactiveUS7639603B2Reduce excessive consumptionHigh trafficError preventionTransmission systemsBackup pathDistributed computing

Owner:FUJITSU LTD

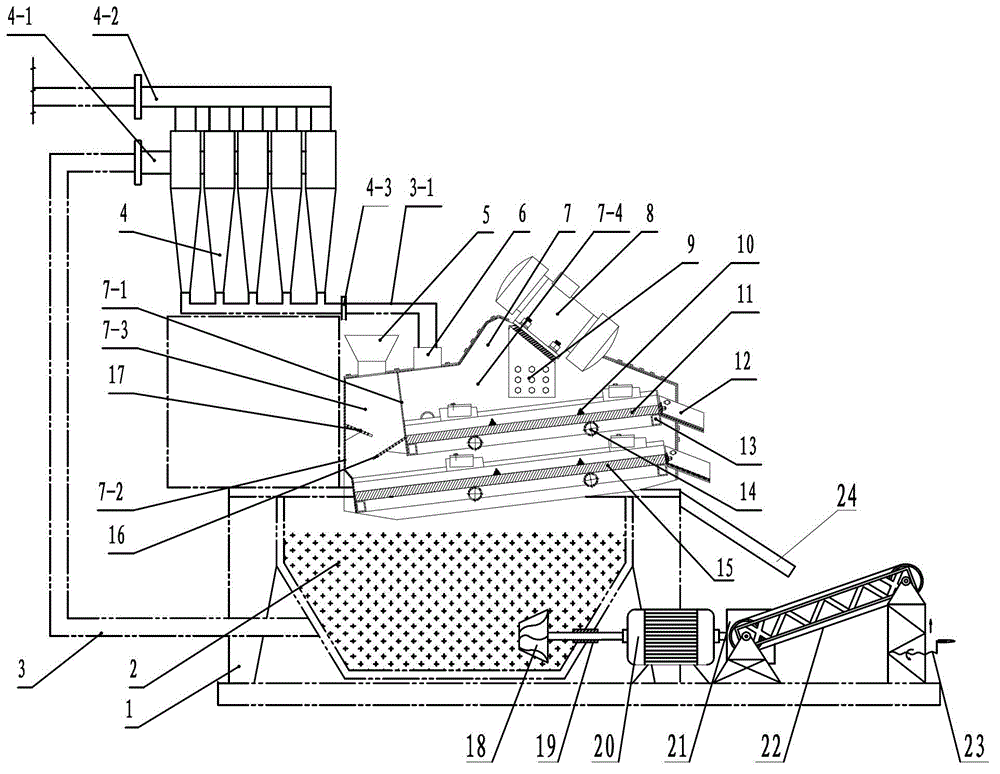

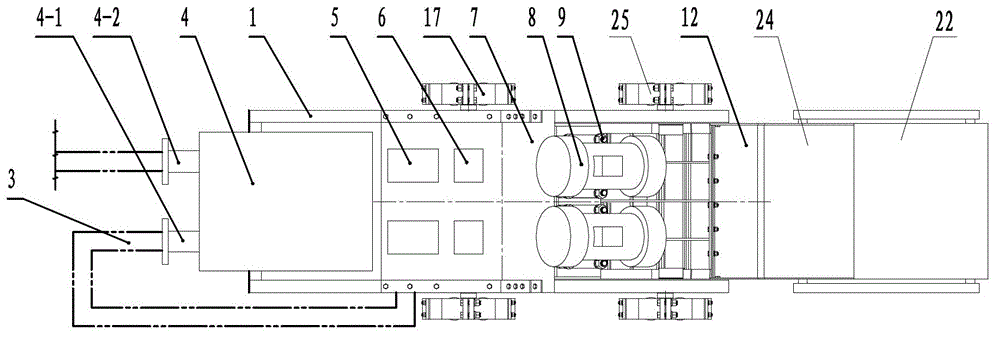

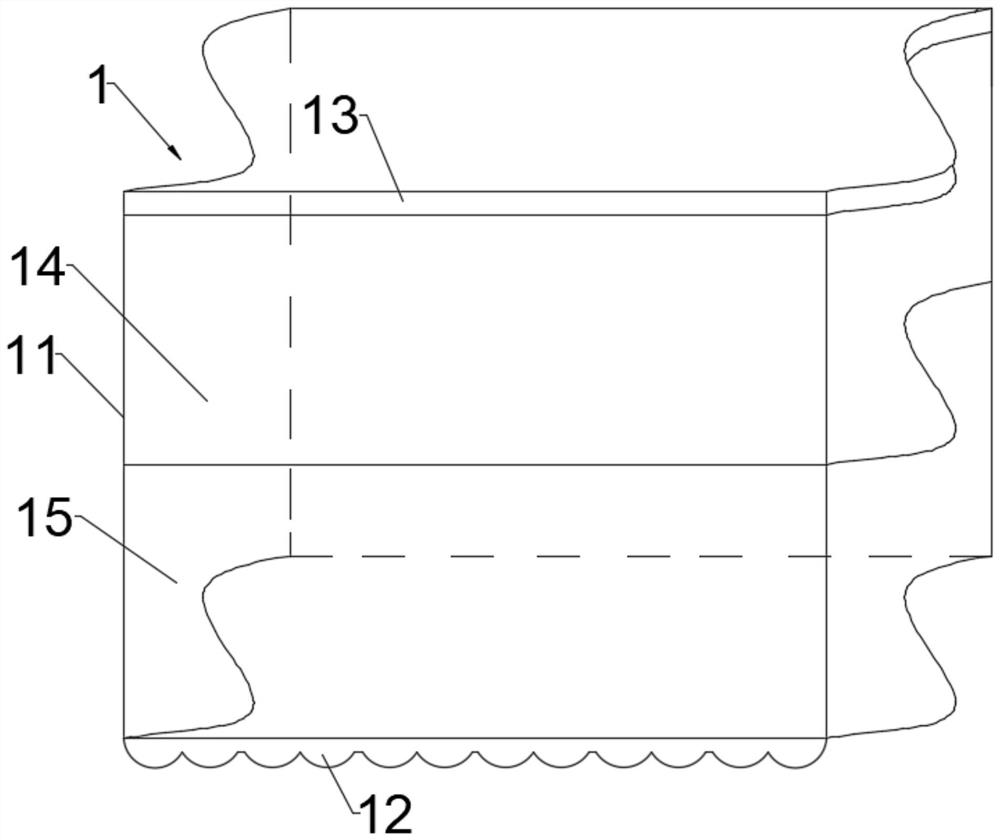

Cast-in-place pile sludge treatment equipment with sludge making and long-distance deslagging functions

InactiveCN103147705ARealize the delivery of pulping materialsRealize functionFlushingDrive wheelSlag

The invention discloses cast-in-place pile sludge treatment equipment with sludge making and long-distance deslagging functions, and belongs to the technical field. The cast-in-place pile sludge treatment equipment comprises a rack, a wedged screen box, vibration motors, a fine sieve plate, a coarse sieve plate, a slurry tank and a swirler unit, wherein discharge ends of the fine sieve plate and the coarse sieve plate are connected with discharge chutes; a discharge plate is mounted at the lower parts of the discharge chutes; a double-shaft motor is mounted at the bottom of the rack; one end of the double-shaft motor stretches into the slurry tank by a mechanical seal; a stirring head is mounted in the slurry tank; the other end of the double-shaft motor is connected with a gear box; a belt conveyor is mounted below the discharge plate; and a driving wheel of the belt conveyor is connected with an output end of the gear box. The cast-in-place pile sludge treatment equipment achieves functions of putting, stirring slurry making, and long-distance slag conveying, which are possessed by sludge treatment equipment.

Owner:徐州格雷安环保设备有限公司

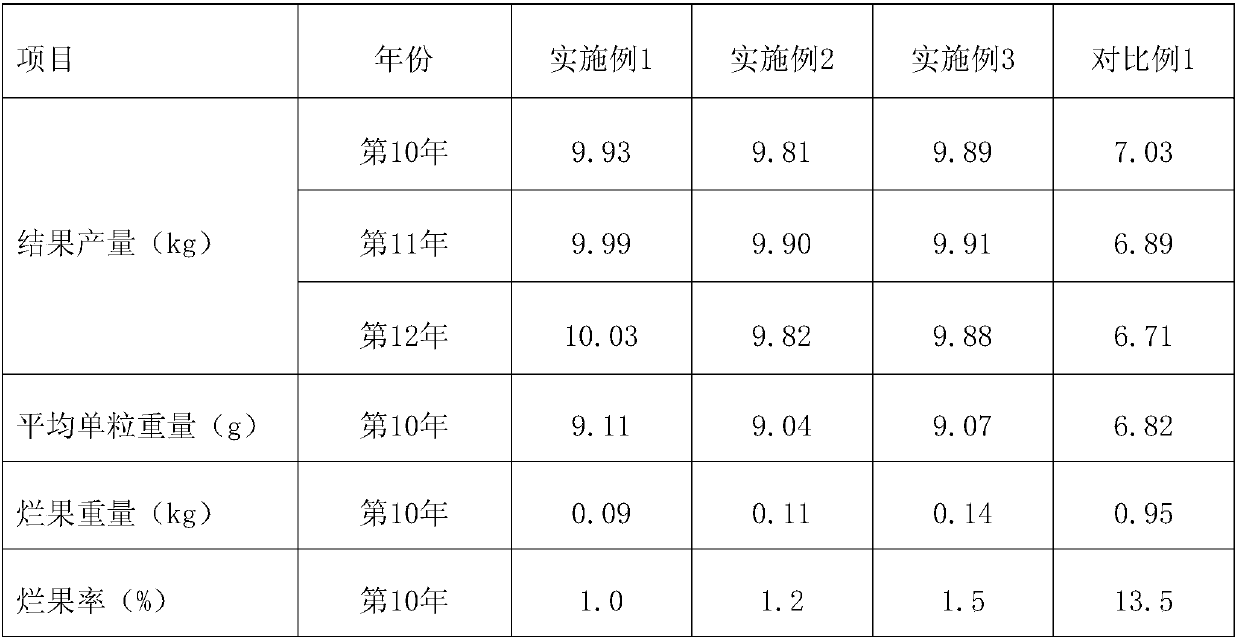

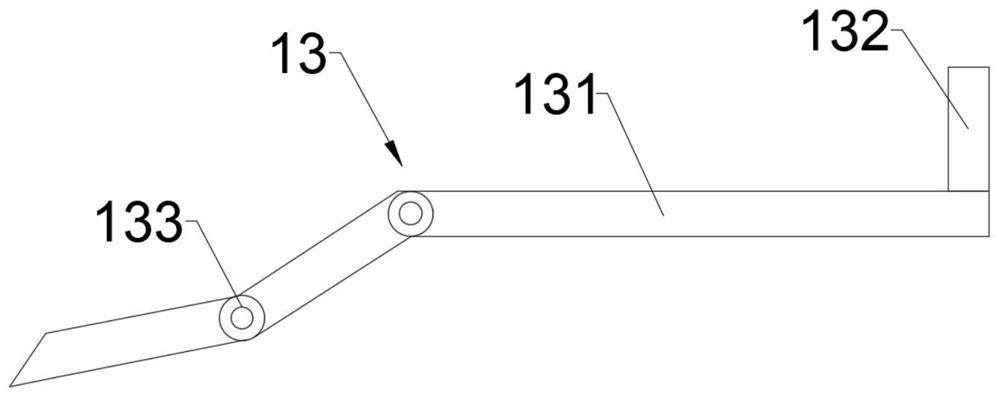

Pruning method of castanea mollissima bearing trees

InactiveCN107691011AReasonable branch distributionTake advantage ofBiocidePlant growth regulatorsInsect pestCastanopsis sclerophylla

The invention discloses a pruning method of castanea mollissima bearing trees and belongs to the technical field of pruning of castanea mollissima trees. According to the pruning method, pruning is conducted after leaves of the castanea mollissima trees completely fall each year. The pruning method comprises the following steps of pruning of the castanea mollissima trees in the early fruiting stage; pruning of the castanea mollissima trees in the full bearing stage, wherein pruning of strong bearing branch groups, treatment of reserved mother branches and thinning of nutrient branches are conducted. According to the growth characteristics of the castanea mollissima trees, the pruning method of the castanea mollissima bearing trees is provided. The pruning method is simple in technology andeasy to operate, reasonable distribution of the shapes and branches of the castanea mollissima trees can be guaranteed, thinning and reservation of the castanea mollissima trees are abstinent, the ventilation and air permeability are good, so that crowns are kept balanced, and leaf areas are increased; meanwhile, plant diseases and insect pests can be reduced, the tree potentials are restored tobe strong, the fruit yield is high, the quality is good, and the purposes of convenient management and increment of production and income are achieved.

Owner:东兰县旺达板栗茶油种植专业合作社

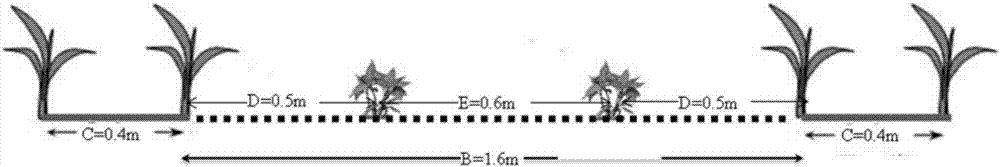

Cultivation method for intercropping of corn and potatoes

InactiveCN107980511AGood characterCarbon richCereal cultivationRoot crop cultivationTotal nitrogenOrganic content

The invention discloses a cultivation method for intercropping of corn and potatoes, and relates to a cultivation method for intercropping of corn and potatoes. The problem that an existing method forintercropping of corn and potatoes cannot sufficiently utilize optical energy and is low in soil resource utilization rate is solved. The method comprises the steps of 1 soil preparation, 2 seed selection and processing, 3 field arrangement, 4 proper sowing and rational close planting, 5 scientific fertilization, 6 precision management and 7 proper harvesting. Compared with monoculture of corn, the soil organic content is increased by 8.5%, and the soil total nitrogen content is increased by 6.4%; the bacterial community number in surface soil microflora is increased by 15.4%, and the mycorrhiza fungi community is increased by 32.6%. The potato yield is 8,700 kg / hm<2>, the corn yield is 11,395 kg / hm<2>, and the corn and potato total income is increased by 4,590 yuan / hm<2>. The method is applicable to the field of corn and potato planting.

Owner:NORTHEAST INST OF GEOGRAPHY & AGRIECOLOGY C A S

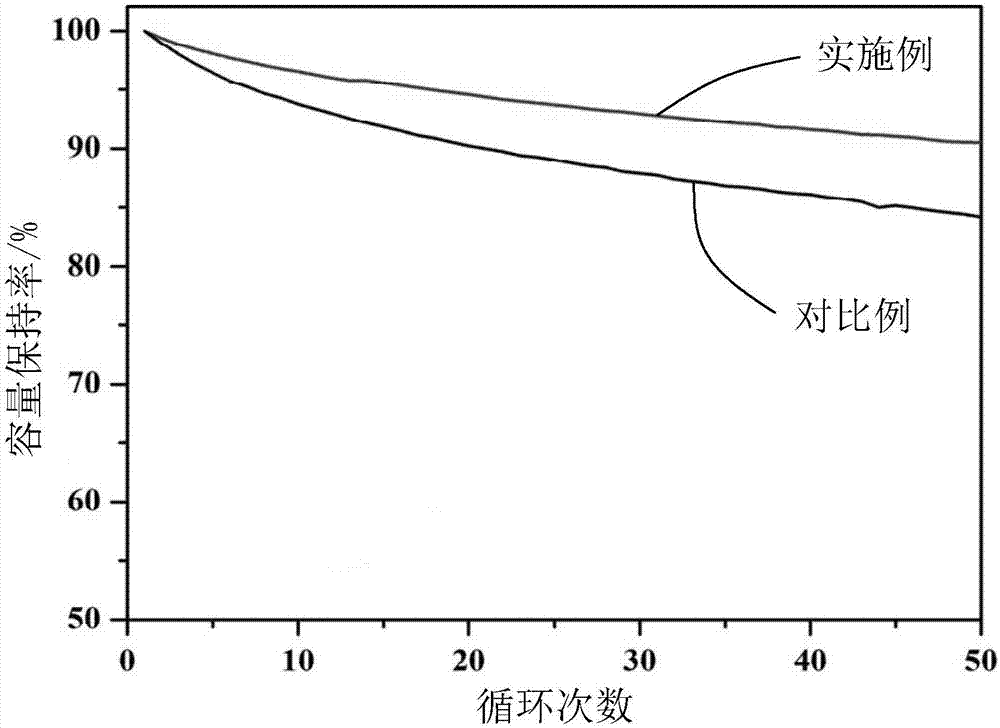

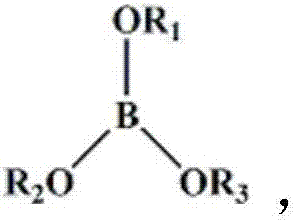

High-temperature electrolyte and lithium ion battery

PendingCN107240717AImprove electrical performanceInhibition of decompositionSecondary cellsOrganic electrolytesSolventDecomposition

The invention provides a high-temperature electrolyte and a lithium ion battery comprising the same. A borate or borane high-temperature agent which is added into the electrolyte can be used for preventing decomposition of LiPF6, reducing reaction of PF5 and a solvent, reducing generation of CO, Co2 and hydrocarbon gas and reducing excessive consumption of the electrolyte and can also be used for capturing F and reducing generation of HF, so that the stability of a positive active material and an SEI membrane are optimized, and the cycle property of the lithium ion battery is improved.

Owner:OPTIMUM BATTERY CO LTD

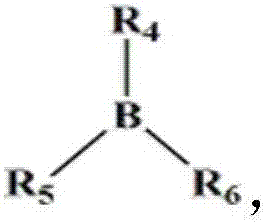

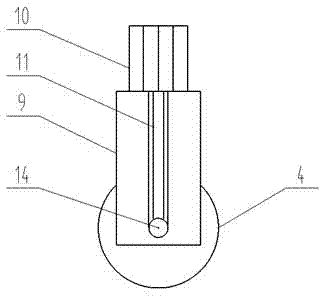

Pre-wetting sizing mechanism

ActiveCN104499222AFully soakedConstant water temperatureTextile treatment machine arrangementsLiquid/gas/vapor yarns/filaments treatmentYarnAutomatic control

The invention provides a pre-wetting sizing mechanism. An electric heater is fixedly arranged at the bottom of a pre-wetting tank and capable of heating water in the pre-wetting tank and keeping the water temperature constant so as to guarantee uniformity in sizing ratio. Meanwhile, yarn is threaded by coordination of an upper pressure roller, a lower pressure roller, an immersing roller and three drawing rollers to be immersed, size can permeate into the yarn fully and beneficially during sizing, and sizing effect is improved effectively. Rotating shafts of the upper pressure roller are fixed on two sides of the pre-wetting tank through supports at two ends, a cylinder is arranged at the tops of the supports, a piston shaft of the cylinder is fixedly connected with the rotating shafts, the upper pressure roller moves up and down in the direction of the supports, automatic control on the upper pressure roller is realized, yarn feeding speed is regulated automatically, and meanwhile, daily maintenance and repair of a sizing machine are facilitated. The pre-wetting sizing mechanism further comprises a liquid level alarm device, when the pre-wetting tank is not full of water or the water is below warning value, water addition information is transmitted to operators through an audible and visual alarm, and the yarn is prevented from being sized non-uniformly due to insufficient immersion.

Owner:IANGSU COLLEGE OF ENG & TECH

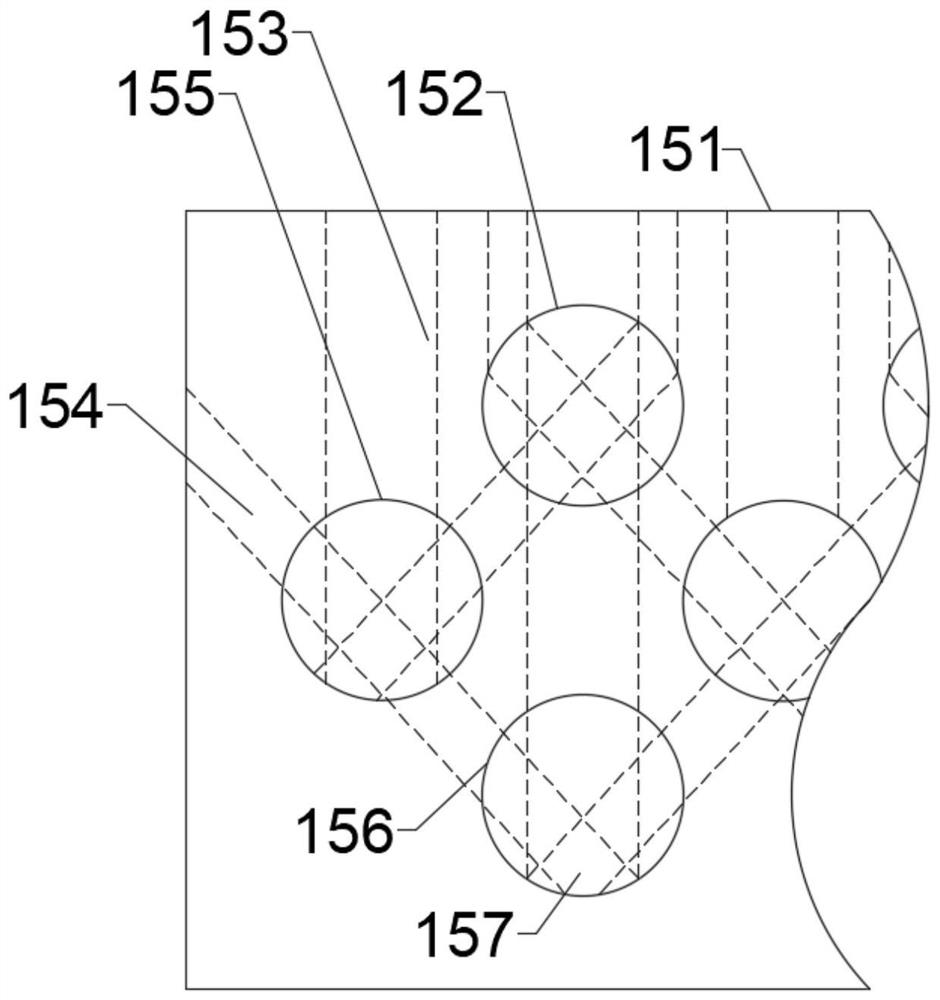

Ecological restoration method and device for eutrophicated riverway water

ActiveCN112194255AReduce excessive consumptionImprove self-cleaning abilityWater resource protectionWater aerationEutrophicationEcoregion

The invention discloses an ecological restoration method and device for eutrophicated riverway water. The device comprises a plurality of integrated multilayer ecological areas arranged in a riverway;any one integrated multilayer ecological area is used for coordinating the restoration capability of the integrated multilayer ecological area and the restoration capability of the adjacent integrated multilayer ecological area by controlling the flow velocity of water flow in the area so as to carry out cooperative restoration on the riverway; and the integrated multilayer ecological area comprises a transparent framework, a flexible balance weight part used for being attached to the bottom of a riverway is installed at the bottom end of the transparent framework, and an algae discarding layer, a plankton control layer and a plant planting layer are arranged on the transparent framework from top to bottom. The riverway is monitored and the pollution source is positioned through the restoration area, and the self-cleaning capacity of the area is improved through multilayer treatment schemes and microcirculation formed among the multiple treatment schemes in the restoration area.

Owner:CCCC TIANJIN DREDGING HARBOR CONSTR ENG

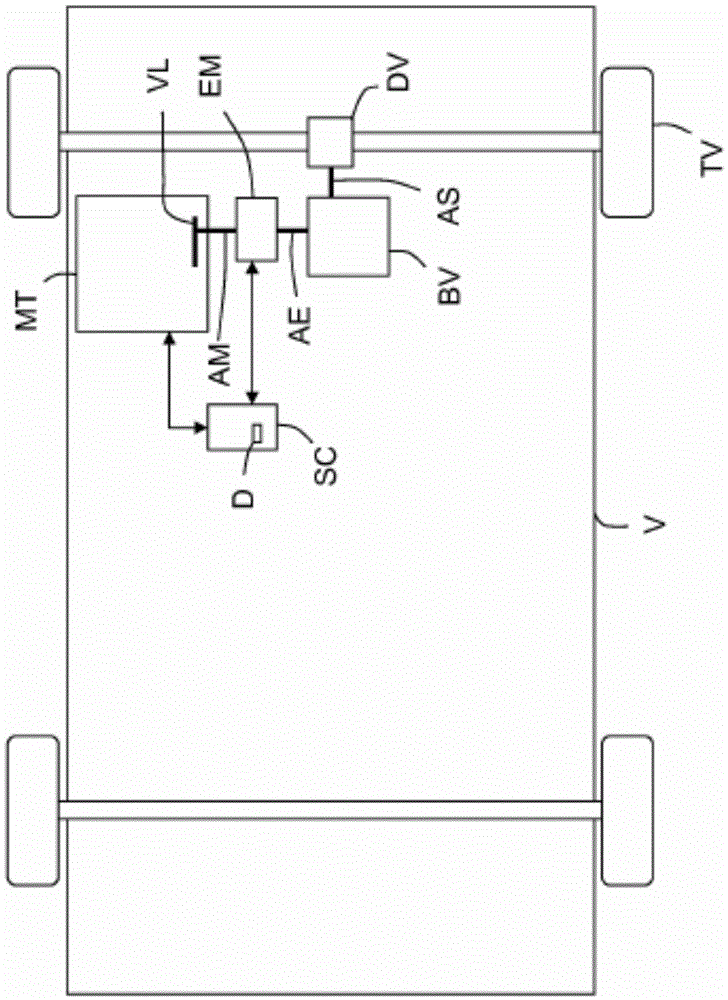

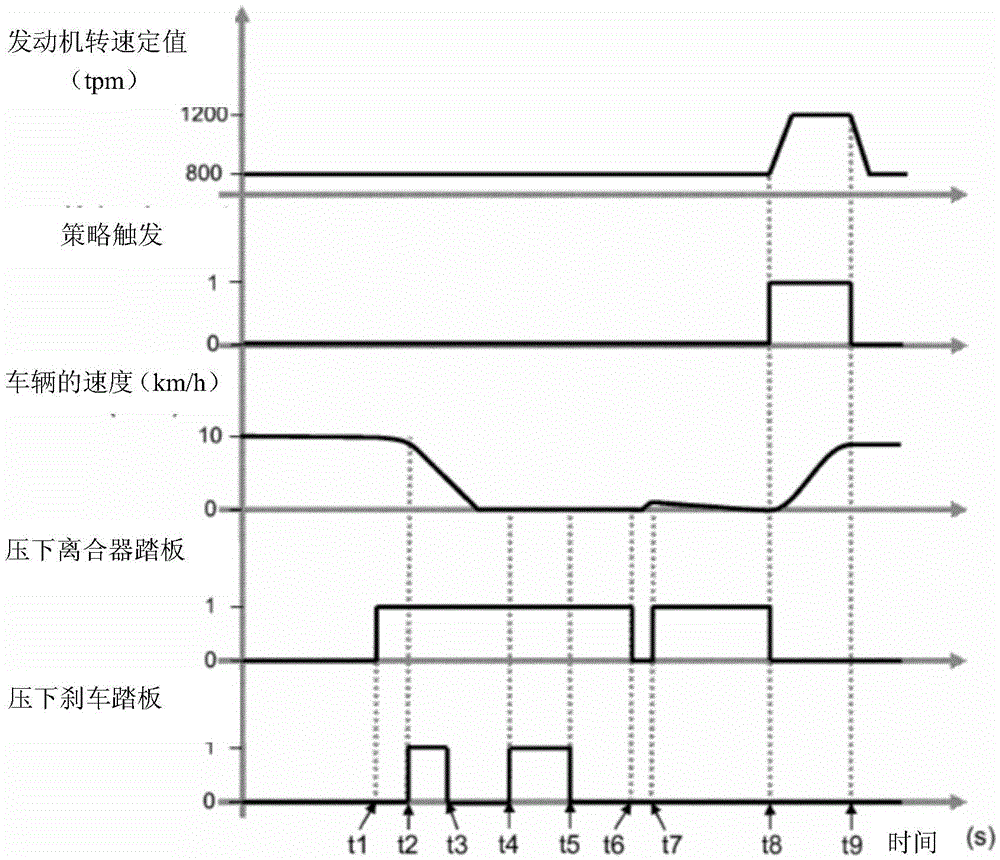

Method and device for detecting short notice acceleration from rest of a vehicle with a heat engine in order to trigger an acceleration-from-rest-assist strategy

ActiveCN105579314AAvoid shockReduce excessive consumptionSpeed sensing governorsMachines/enginesPowertrainCrankshaft

The invention relates to a device (D) which is intended for detecting "short notice" acceleration from rest of a vehicle (V) with a power train including a crankshaft (VL), in order to trigger an acceleration-from-rest-assist strategy intended for increasing the set speed of a speed-limiting governor of said vehicle (V). Said device (D) is arranged such as to detect short notice acceleration from rest in the event of the detection of: the clutch pedal being pressed, the brake pedal not being pressed, a vehicle speed (V) of substantially zero, and the transmission of at least one selected torque to the crankshaft (VL).

Owner:PEZHO SITROEN AUTOMOBILS SA

Asphalt high-temperature cleaning machine for test pipe bottle

The invention discloses an asphalt high-temperature cleaning machine for a test pipe bottle. The asphalt high-temperature cleaning machine comprises a cleaning box body; a test pipe storage plate is arranged in the cleaning box body; a plurality of test pipe inserting holes are formed in the test pipe storage plate; fixing sliding blocks are arranged on the inner walls of the test pipe inserting holes; a cleaning plate is arranged below the test pipe storage plate; a plurality of self-rotating cleaning nozzles are vertically arranged on the cleaning plate and located under the test pipe inserting holes; a test pipe heating plate is arranged above the test pipe storage plate; a plurality of upwards-convex heating grooves are formed in the bottom surface of the test pipe heating plate; heating wires are arranged in the heating grooves; and the heating grooves are located over the test pipe inserting holes. According to the asphalt cleaning machine, the bottoms of test pipes are heated, asphalt can be softened, then the test pipes are rinsed, thus asphalt quick cleaning can be achieved, the asphalt cleaning efficiency is improved, and excessive consumption of a solvent and heat energy is reduced.

Owner:四川宝利沥青有限公司

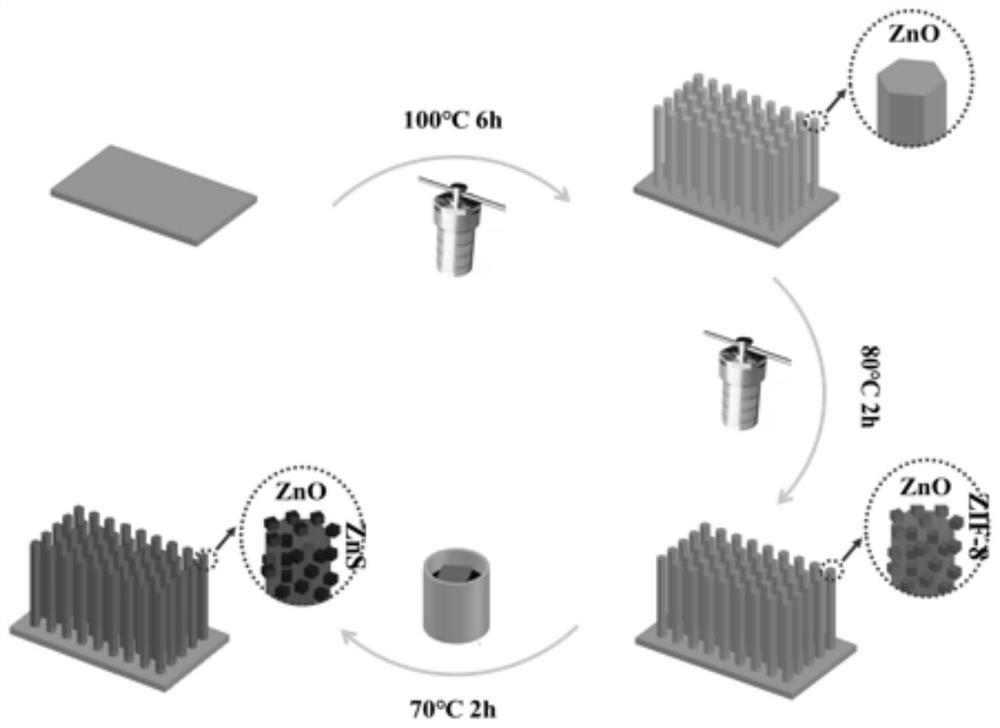

Zinc oxide/zinc sulfide composite film photoelectrode and solar photodeposition precious metal recovery device

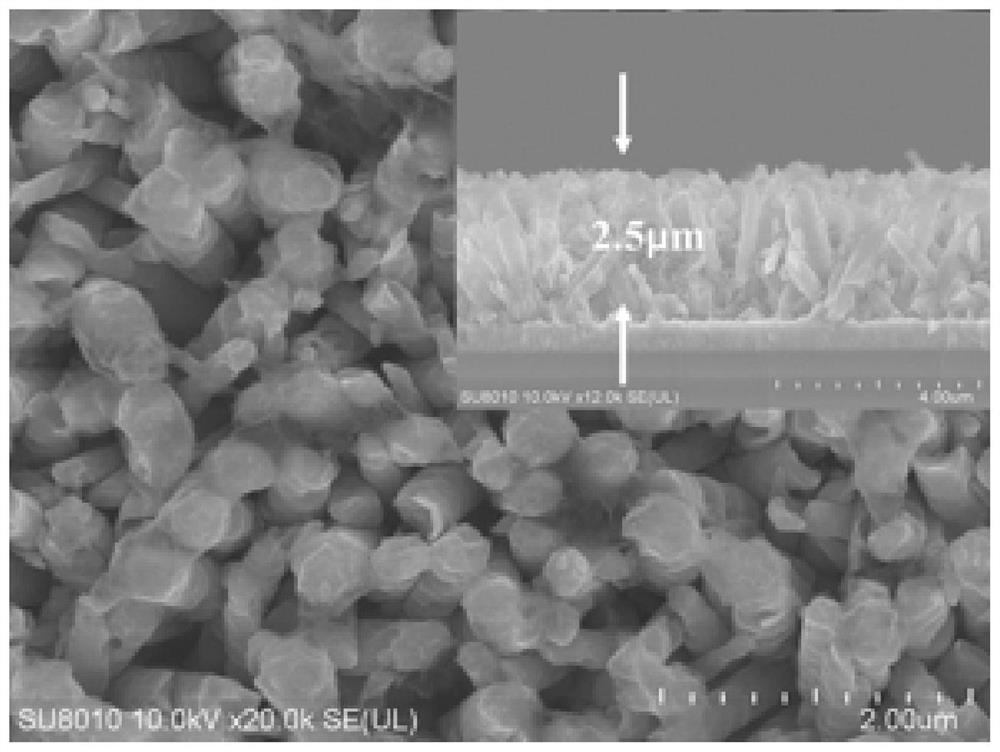

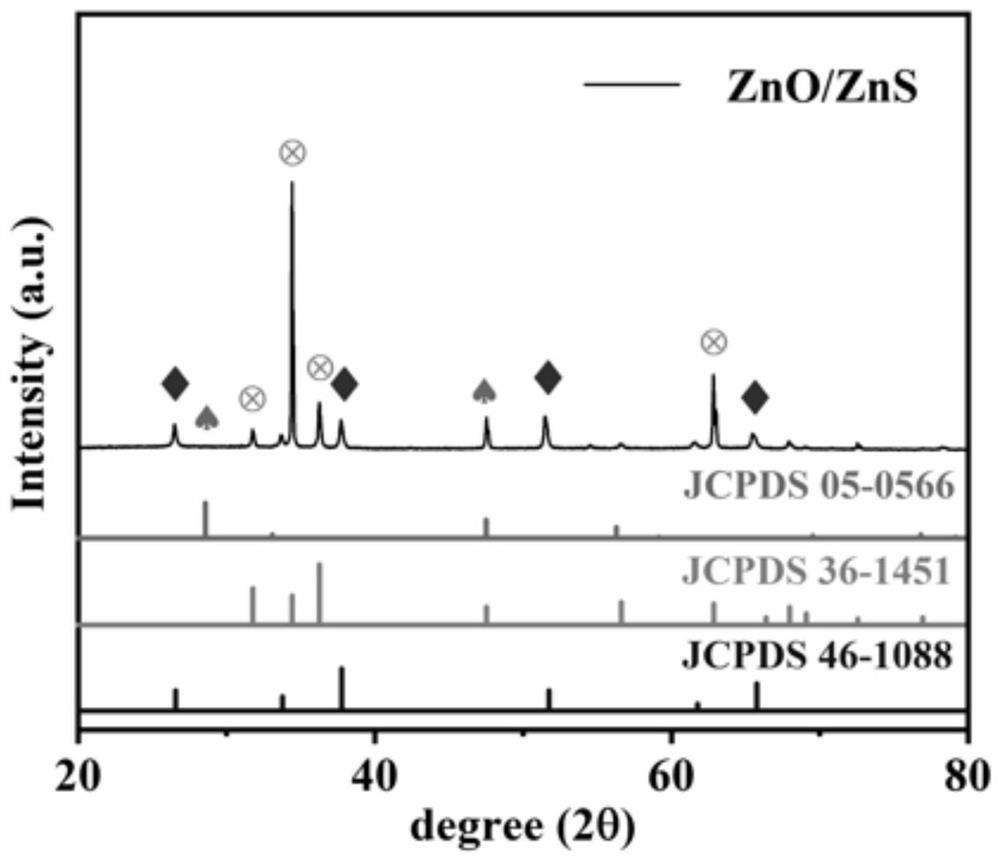

PendingCN113481546AAchieving collaborative transformationImprove photocatalytic performancePhotography auxillary processesZinc oxides/hydroxidesComposite filmChemical engineering

The invention relates to the technical field of photodeposition and photocatalysis, in particular to a zinc oxide / zinc sulfide composite film photoelectrode and a solar photodeposition precious metal recovery device. A preparation method of the zinc oxide / zinc sulfide composite film photoelectrode comprises the following steps of ultrasonically cleaning conductive glass by acetone, ethanol and water in sequence, and drying to remove redundant water on the surface; preparing a zinc oxide film through a hydrothermal reaction; after secondary hydrothermal treatment, generating a ZnO / ZIF-8 precursor in situ; and vulcanizing the ZnO / ZIF-8 precursor into ZnO / ZnS, and obtaining the zinc oxide / zinc sulfide composite film photoelectrode. The ZnO / ZnS composite film photoelectrode and blank conductive glass are assembled by utilizing an H-shaped electrolytic bath to obtain the solar photodeposition precious metal recovery device. The deposition device can deposit Au, Ag and Pt noble metals from a solution by directly utilizing solar energy.

Owner:LIAONING UNIVERSITY

Application of amino acid as soil phosphorus release agent

InactiveCN102351612AReduce excessive consumptionReduce churnFertilizer mixturesHydrolysatePhosphorite

The invention discloses a double-effect application of amino acid as a soil phosphorus release agent and a plant nitrogen fertilizer. An amino acid fertilizer capable of releasing soil phosphorus elements and simultaneously providing plant nitrogen fertilizers is prepared according to the application. The amino acid can be natural amino acid or proteolysis hydrolysate or artificially synthesized amino acid. The amino acid can be directly used as phosphorus release organic fertilizers and can also be matched with inorganic fertilizers to produce double-effect composite fertilizers. Pot cultureor field fertilizer effect experiments of corn, rice and vegetables all prove that the amino acid has the function of double-effect fertilizers, can be used as efficient nitrogen fertilizers and can also simultaneously replace phosphorus fertilizers, the absorption of crops on the phosphorus in the soil can be promoted, the phosphorus fertilizers are reduced or are not applied, and the phosphorusore resource exhausted crisis is greatly relieved.

Owner:SOUTHWEST UNIVERSITY +1

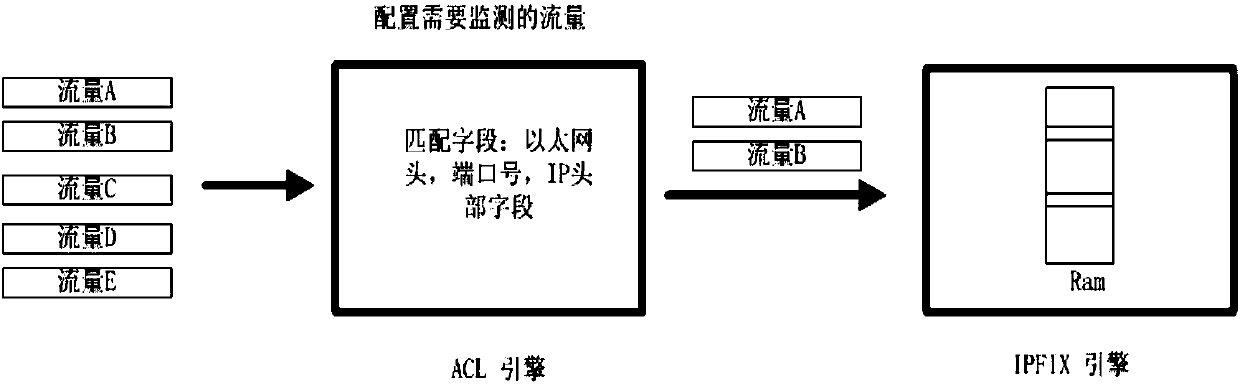

Traffic based method and device implementing ipfix detection

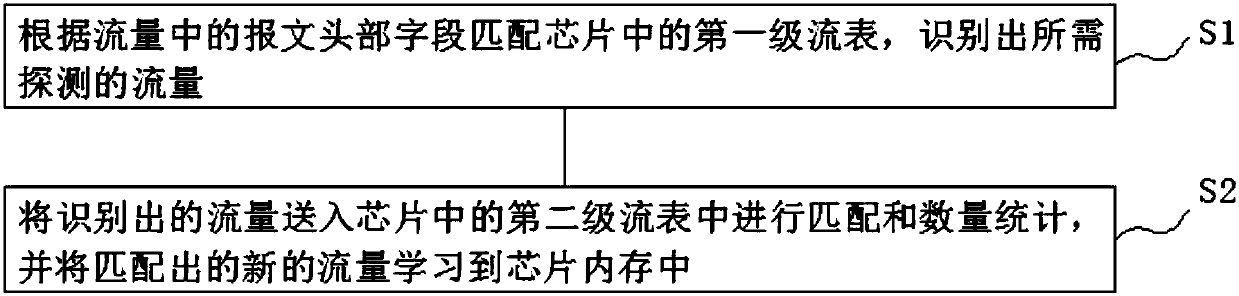

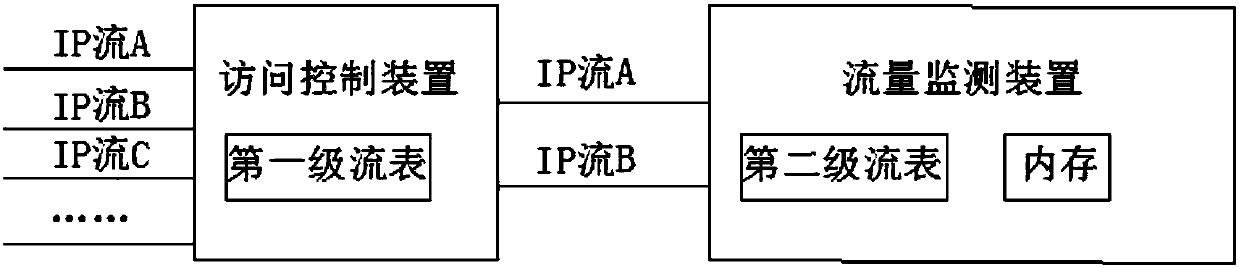

ActiveCN107566220AEasy to identifyReduce excessive consumptionData switching networksTraffic volumeTraffic capacity

The invention discloses a traffic based method and device implementing ipfix detection. The method includes identifying to-be-detected traffic according to a first level flow table in a message head field matching chip in traffic; sending identified traffic into a second level flow table in the chip for matching and number statistics and learning matched new traffic into memory of the chip. According to the invention, ipfix is implemented by adopting the method of two level flow meters, so that ipfix has the capability of acting as a detection point based on traffic, the identification degreeof to-be-monitored traffic can be improved and thus excessive consumption of ipfix memory due to non-related traffic is reduced.

Owner:SUZHOU CENTEC COMM CO LTD

Electricity generating device for body-building boating apparatus

InactiveCN102477963AAlleviate excessive consumptionImprove work efficiencyFrom muscle energyMachines/enginesElectricityEngineering

The invention discloses an electricity generating device for a body-building boating apparatus, and the electricity generating device comprises a pulling handle mounted in the front of a seat of the body-building boating apparatus, an air pump positioned below the seat, an air storing tank positioned below the air pump, and a steam turbine generator. The pulling handle is connected with a piston rod on the air pump; the air pump is connected with the air storing tank through a first air pipe; and the air storing tank is connected with a steam turbine cavity of the steam turbine generator through a second air pipe. By using the electricity generating device for the body-building boating apparatus, the physical energy consumed in the body-building process of people is converted into electric energy, and further, the electricity generating device for the body-building boating apparatus has a simple structure, is convenient to use, and is convenient to popularize and use.

Owner:XIAN DAYU PHOTOELECTRIC TECH

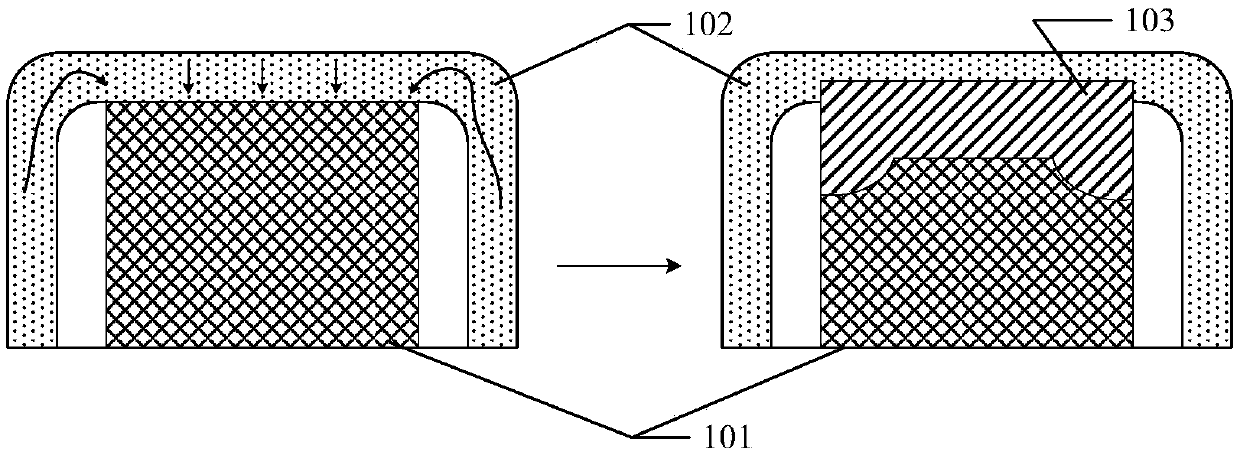

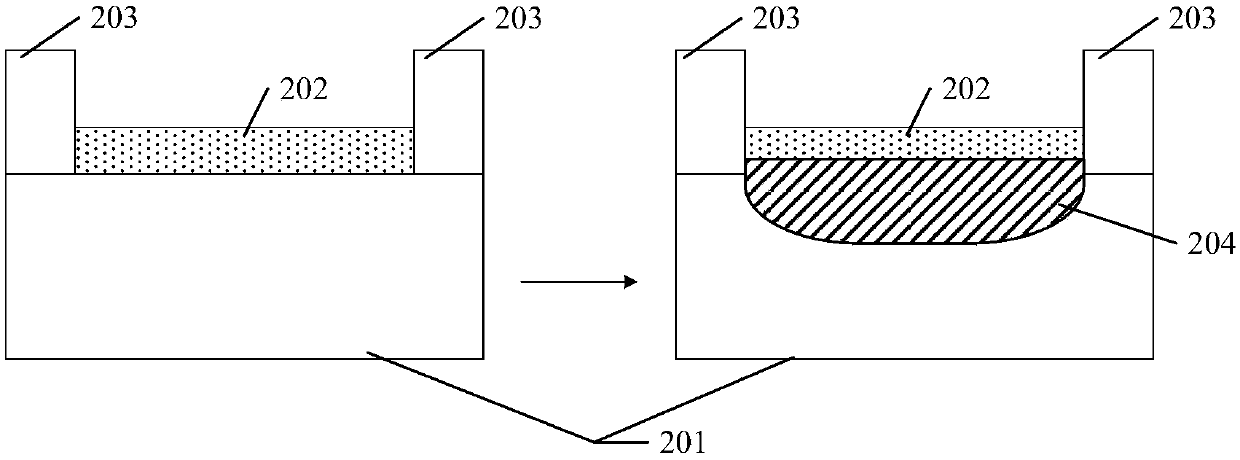

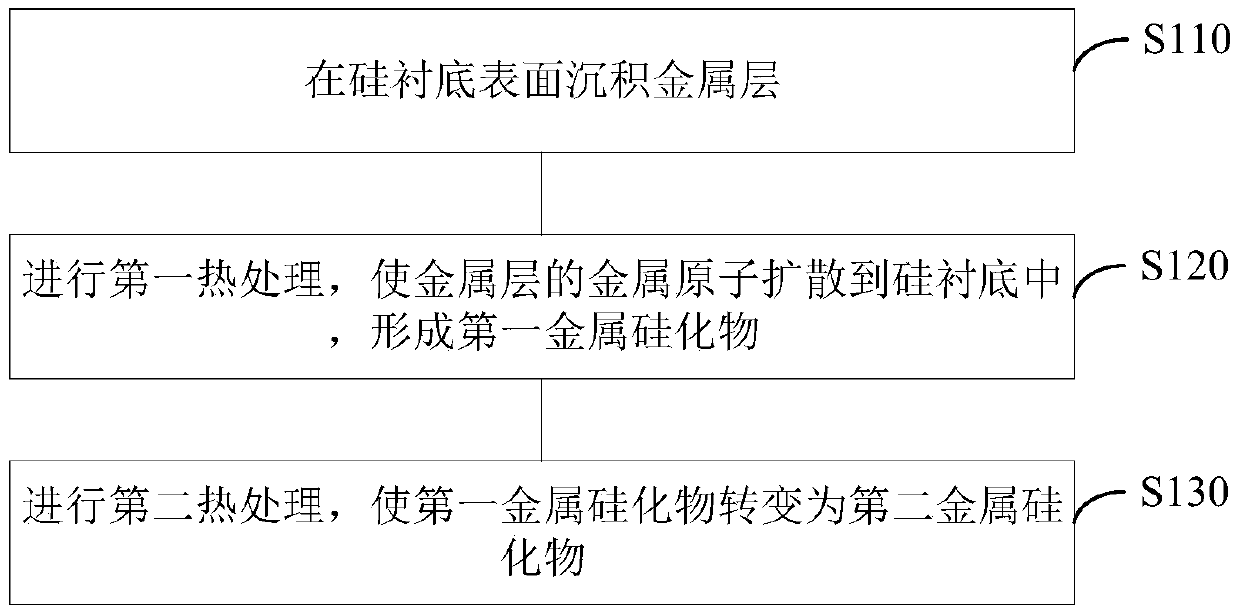

Metal silicide forming method

ActiveCN110890275AImprove thickness uniformityReduce the degree of diffusionSemiconductor/solid-state device manufacturingSemiconductor devicesDevice materialMetal silicide

The invention provides a metal silicide forming method, and belongs to the technical field of semiconductors. The method comprises the following steps: depositing a metal layer on the surface of a silicon substrate; performing first heat treatment to diffuse metal atoms of the metal layer into the silicon substrate to form a first metal silicide; carrying out second heat treatment to convert the first metal silicide into second metal silicide, wherein the temperature of the first heat treatment is lower than that of the second heat treatment. According to the invention, excessive diffusion ofmetal atoms in the forming process of the metal silicide can be reduced, the thickness uniformity of the metal silicide is improved, the performance of a semiconductor device is improved, and the service life of the semiconductor device is prolonged.

Owner:CHANGXIN MEMORY TECH INC

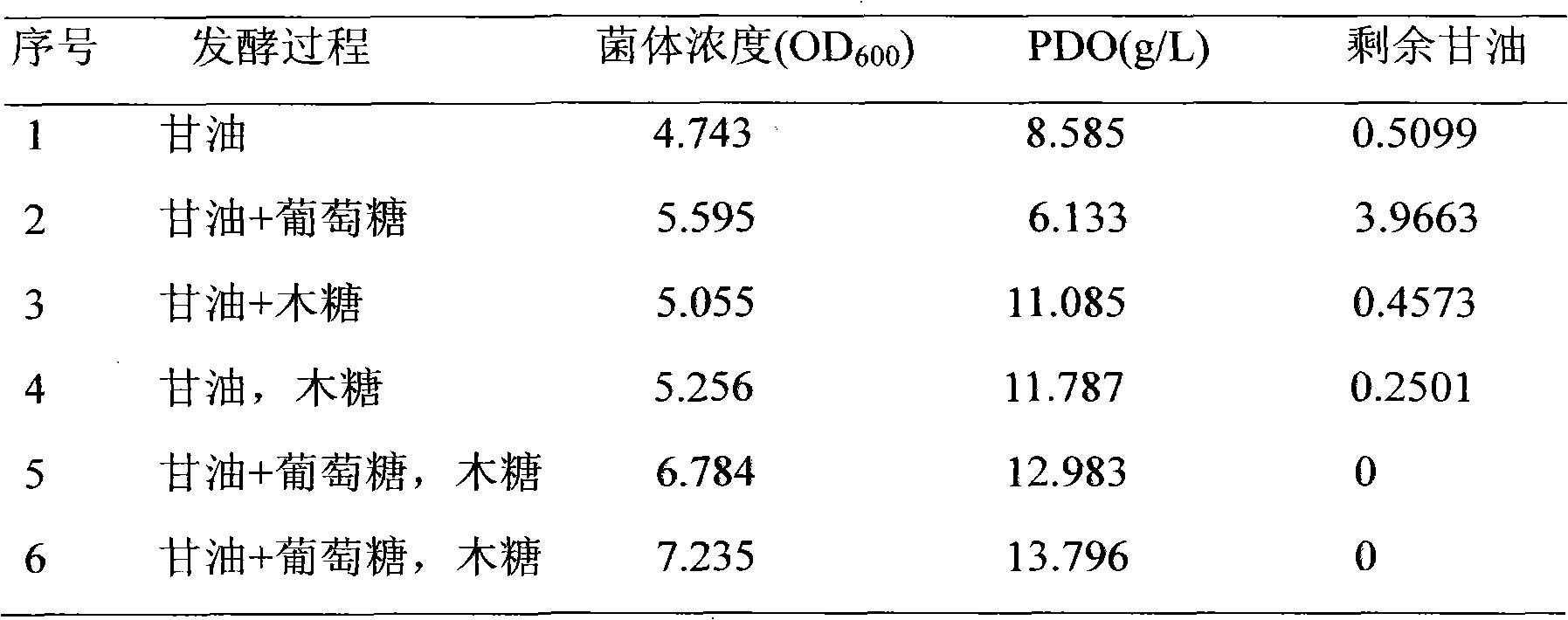

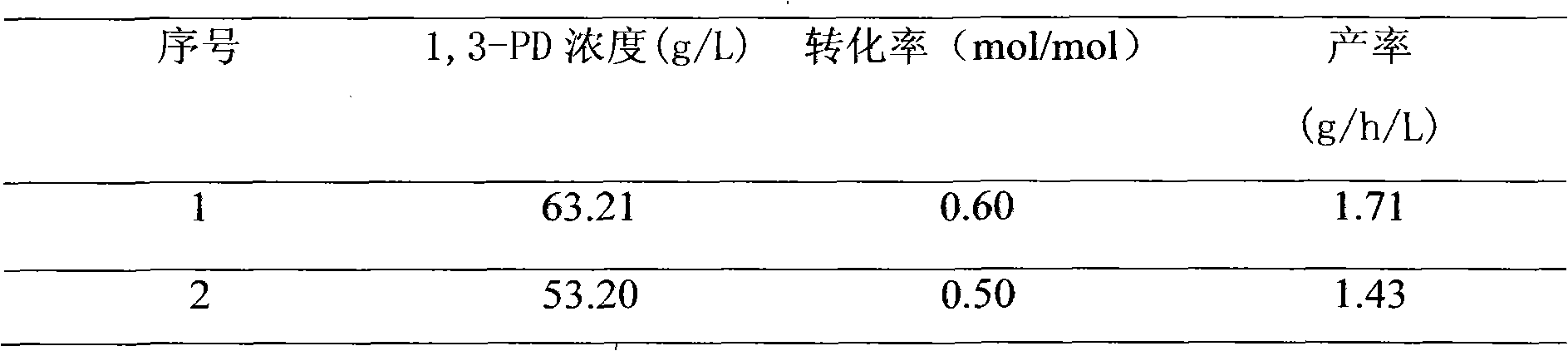

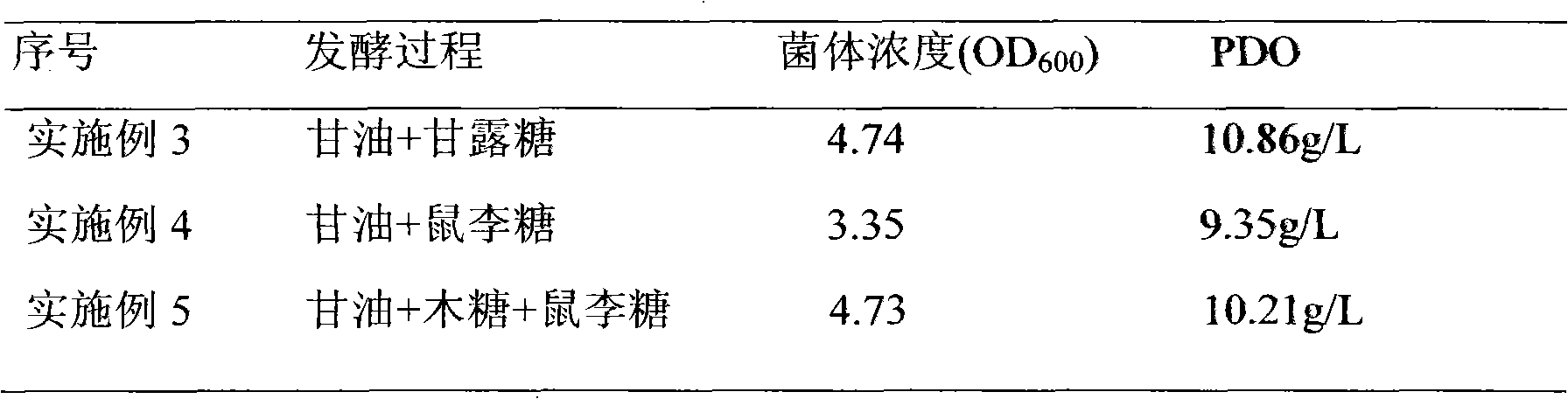

Method for promoting to biosynthesize 1,3-propylene glycol by adding reducing sugar

ActiveCN102311979AReduce excessive consumptionLow priceMicroorganism based processesFermentation1,3-PropanediolXylose

The invention relates to a method for promoting to biosynthesize 1,3-propylene glycol by adding reducing sugar, which comprises the following steps: preparing a fermentation medium used for the 1,3-propylene glycol; by taking glycerol as a fermentation substrate, inoculating a Klebsiella pneumonia strain culture solution into the fermentation medium to carry out anaerobic fermentation or microaerophillic fermentation to synthesize the 1,3-propylene glycol; and in the fermentation process, introducing the reducing sugar of which the fermentation system concentration is 1-50g / L. In the method for promoting to biosynthesize the 1,3-propylene glycol by adding the reducing sugar, according to the characteristic of xylose, mannose, rhamnose and the like producing a large number of reducing equivalents in the metabolic pathway in a bacterium body, by utilizing the principle that the biosynthesis of the 1,3-propylene glycol can be promoted because of the existence of more reducing equivalents, a good amount of reducing sugar is added to the fermentation medium to increase the reducing equivalents, and thereby, the synthesis concentration and the conversion rate of the 1,3-propylene glycolare improved. The method for promoting to biosynthesize the 1,3-propylene glycol by adding the reducing sugar is simple to operate, is capable of improving the bioavailability and reducing the fermentation cost and is suitable for industrial production.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com