Pre-wetting sizing mechanism

A pre-wetting, pre-wetting tank technology, applied in textile processing machine accessories, textile and papermaking, textile material processing and other directions, can solve the problems affecting the penetration of the sizing liquid to the yarn, poor sizing effect, insufficient sizing rate, etc., to achieve convenient Daily maintenance and repair, avoid uneven sizing, and improve the effect of sizing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

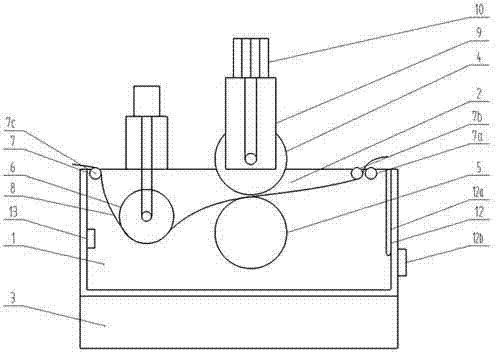

[0016] In order to make the purpose, technical solution and advantages of the present invention clearer, the following will further describe the implementation of the present invention in detail in conjunction with the accompanying drawings.

[0017] like figure 1 As shown, the main body of the pre-wet sizing mechanism is a pre-wet tank 1 and a pre-wet roller group 2, the pre-wet roller group 2 is fixed inside the pre-wet tank 1, the bottom of the pre-wet tank 1 is fixed with an electric heater 3, and the electric heater 3. The outer contour is the same as that of the bottom of the pre-wetting tank 1, and the electric heater 3 is close to the bottom of the pre-wetting tank 1, which can heat the water in the pre-wetting tank 1, keep the water temperature constant, and improve the sizing effect.

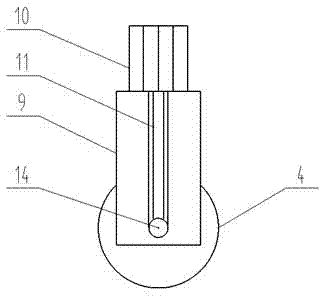

[0018] The pre-wetting roller group 2 includes an upper pressing roller 4, a lower pressing roller 5, a immersion roller 6 and three yarn-drawing rollers 7. The upper pressing roller 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com