Method for promoting to biosynthesize 1,3-propylene glycol by adding reducing sugar

A technology for biosynthesis, propylene glycol, used in microorganism-based methods, biochemical equipment and methods, microorganisms, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

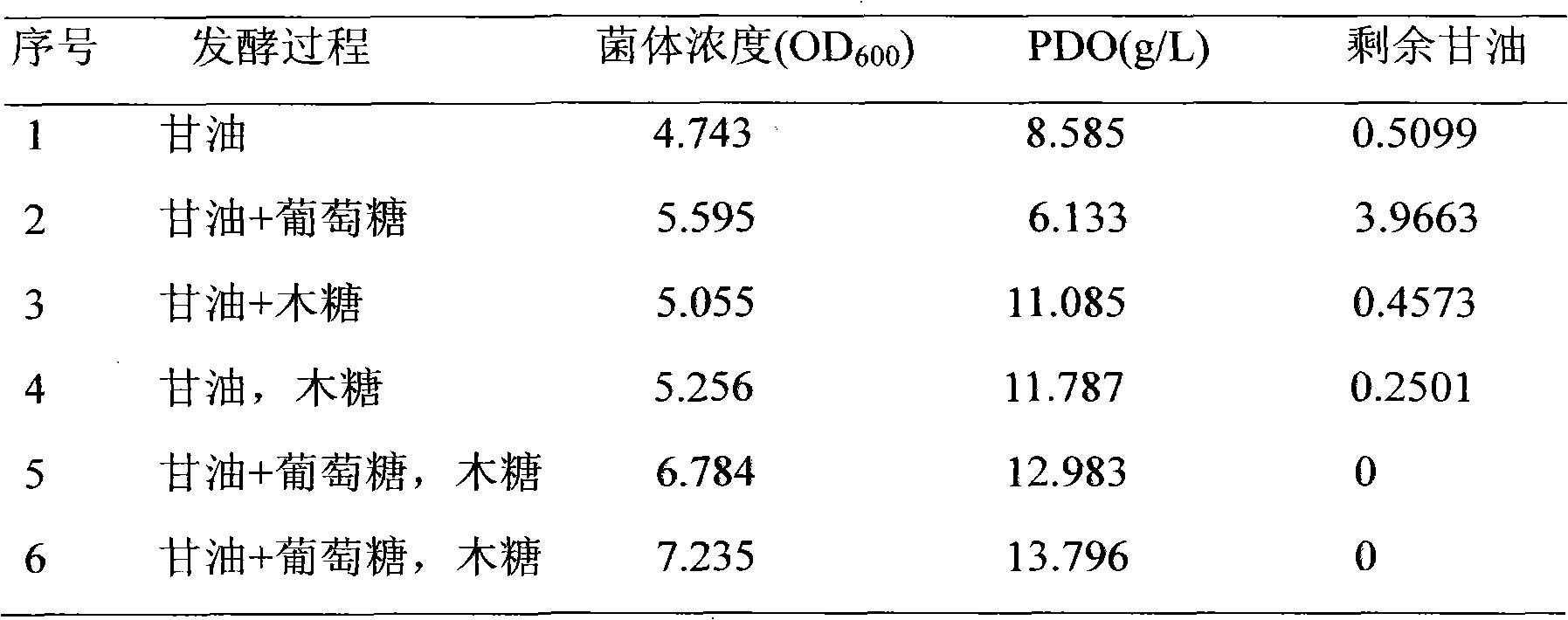

[0014] Embodiment 1 Adding xylose to increase reducing equivalent is fermented in shake flask

[0015] Bacterial species: Klebsiella pneumoniae (Klebsiella pneumoniae) was screened by Fushun Petrochemical Research Institute, and preserved in China Microorganism Culture Collection Center (CGMCC), No. 0798. LB solid medium: Each liter of medium contains peptone 10.0g / L, yeast extract 5.0g / L, NaCl 10.0g / L, pH 7.0.

[0016] Seed medium: yeast extract 5.0g / L, maltose 3.0g / L, peptone 5.0g / L, NaCl 5.0g / L, pH 7.0.

[0017] Fermentation medium: yeast extract 5.0g / L, K 2 HPO 4 ·3H 2 O 10g / L, KH 2 PO 4 2g / L, NH 4 Cl 1g / L, NaCl 0.5g / L, MgSO 4 ·7H 2 O 0.1g / L, FeCl 3 ·6H 2 O 30mg / L, CoCl 2 ·6H 2 O5mg / L, Vitamin B 12 (Vitamin B 12 ) 5mg / L, glycerol (glycerin) 30g / L, pH 7.0, reducing sugar (xylose, mannose, rhamnose, etc.) concentration is 0-20g / L.

[0018] Fermentation process:

[0019] Step 1: Activation of strains

[0020] Pick a ring of Klebsiella pneumonia from the glyc...

Embodiment 2

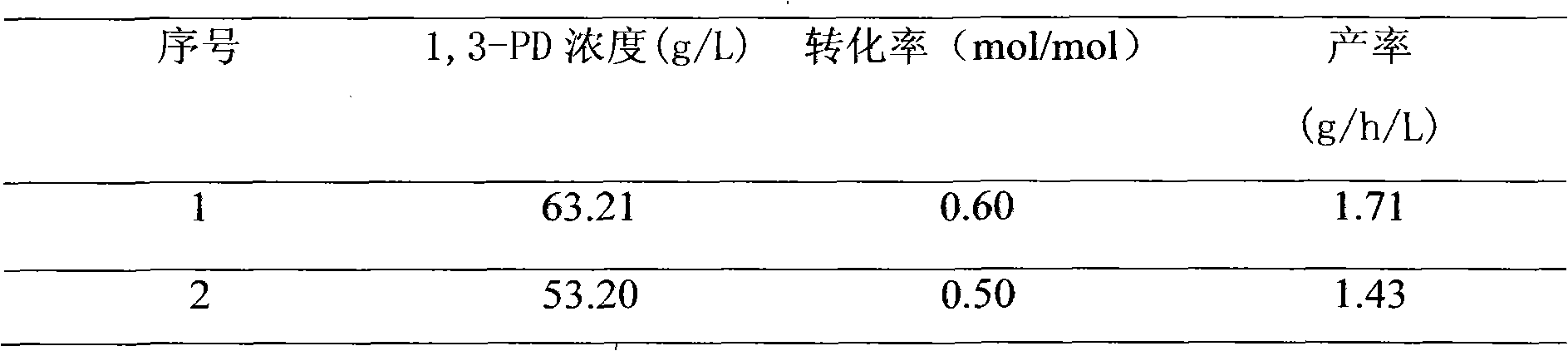

[0035] Example 2 Adding xylose to increase reducing equivalent is fermented in a 7 liter fermenter

[0036] During the fermentation process, the seed solution was inserted into a 7-liter fermenter, and the filling capacity was 4 liters. The fermentation medium contains a glucose concentration of 5g / L, an inoculum size of 5%, microaerobic fermentation (0.25vvm air), 37°C, 300rpm. All the other conditions refer to Example 1. Samples were taken every 6 hours, and the measured items included bacterial cell concentration, substrate glycerin concentration, synthesis concentration of 1,3-propanediol and concentration of other main by-products.

[0037] Experiment No. 1 added xylose every 6 hours after fermentation for 6 hours, adding xylose each time to make the fermentation system contain 4g / L xylose.

[0038] Experiment No. 2 added glucose every 6 hours after fermentation for 6 hours, adding glucose each time to make the fermentation system contain 4 g / L of glucose.

[0039] Exp...

Embodiment 3

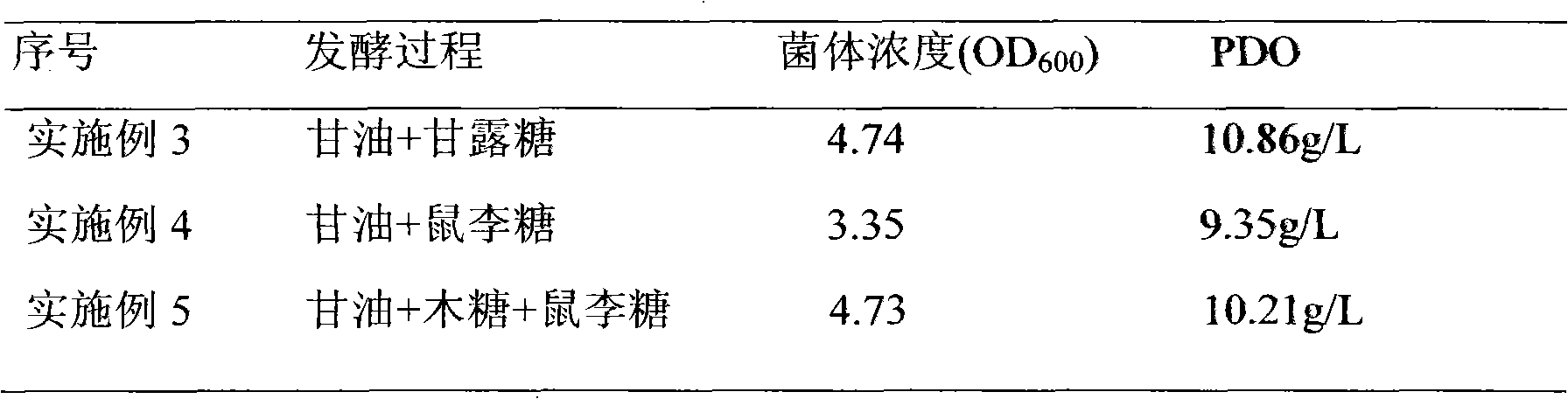

[0044] Embodiment 3 adds mannose in fermentation medium

[0045] In a 250mL shake flask equipped with 100mL of fermentation medium (the mannose content is 10g / L), the inoculum size was 2%, 37°C, 140°C, and the incubation time was 30h. All shake flasks are narrow-mouth bottles with rubber stoppers. Sampling was taken every 5 hours in the middle, and the volume of each sampling was 4mL. The measured items included bacterial cell concentration, substrate glycerol and mannose concentration, synthesis concentration of 1,3-propanediol and concentration of other main by-products. For strain activation and seed cultivation, refer to Example 1. The experimental results are shown in Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com