Zinc oxide/zinc sulfide composite film photoelectrode and solar photodeposition precious metal recovery device

A technology of zinc oxide thin film and composite thin film, applied in the direction of zinc oxide/zinc hydroxide, zinc sulfide, electrodes, etc., can solve the problem of no precious metals being found, achieve environmental friendliness, promote separation and migration, excellent photocatalytic activity and stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

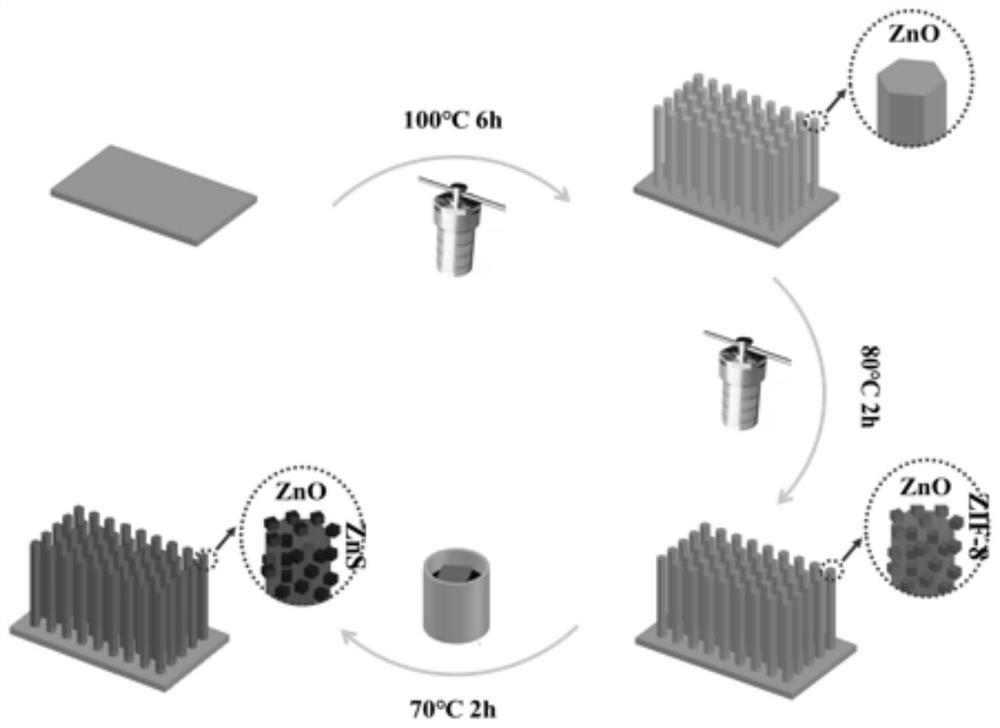

[0037] Embodiment 1 A kind of zinc oxide / zinc sulfide composite film photoelectrode

[0038] (1) preparation method comprises the steps:

[0039] 1) Preparation of zinc oxide thin film seed layer: including the following steps: dissolving zinc nitrate hexahydrate in ethanol and ultrasonically dissolving it fully to obtain a zinc nitrate ethanol solution with a concentration of 0.005M. Add 0.8mL of the prepared ethanol solution of zinc nitrate dropwise on the surface of the blank FTO, and dry it in a vacuum oven at 70°C. This process is repeated three times, and then transferred to a muffle furnace for sintering at a high temperature of 450°C for 15 minutes, and naturally cooled to room temperature to obtain ZnO seed layer. Dissolve 0.1M zinc nitrate hexahydrate and 0.2M hexamethylenetetramine in 50mL of deionized water, and ultrasonically dissolve them fully. Finally, transfer the mixed solution and the FTO containing the ZnO seed layer to a polytetrafluoroethylene-lined rea...

Embodiment 2

[0044] Embodiment 2 A recovery device utilizing solar photoinduced deposition of precious metals

[0045] Such as Figure 4 As shown, the structure of a recovery device for an H-type electrolytic cell that directly utilizes solar photoinduced deposition of precious metals is as follows: a zinc oxide / zinc sulfide composite film electrode based on FTO conductive glass is used as a photoelectrode, a blank FTO conductive glass is used as a counter electrode, and the electrolyte They are respectively 0.02% chloroplatinic acid, 0.02% chloroauric acid, and 0.02% silver nitrate solution with a mass fraction of 0.02%, and simulated sunlight (500W xenon lamp as light source, AM 1.5 type filter, incident light intensity is 100mW) / cm 2 ) under. Figure 4 On the right is a picture of Au, Ag, Pt thin films photo-deposited on the surface of FTO.

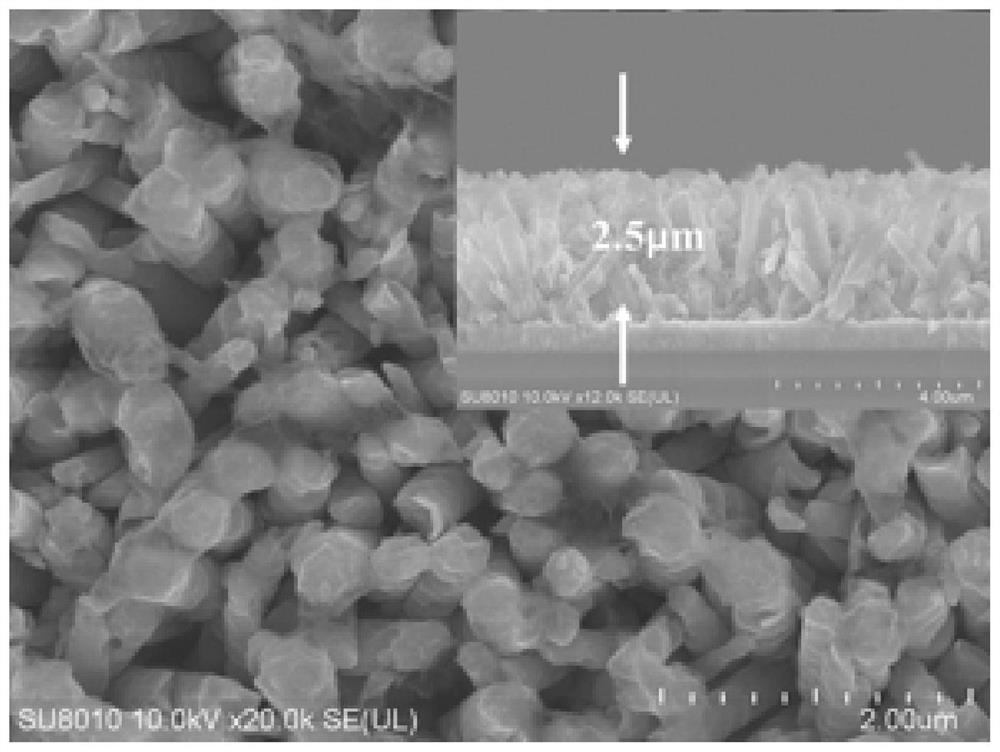

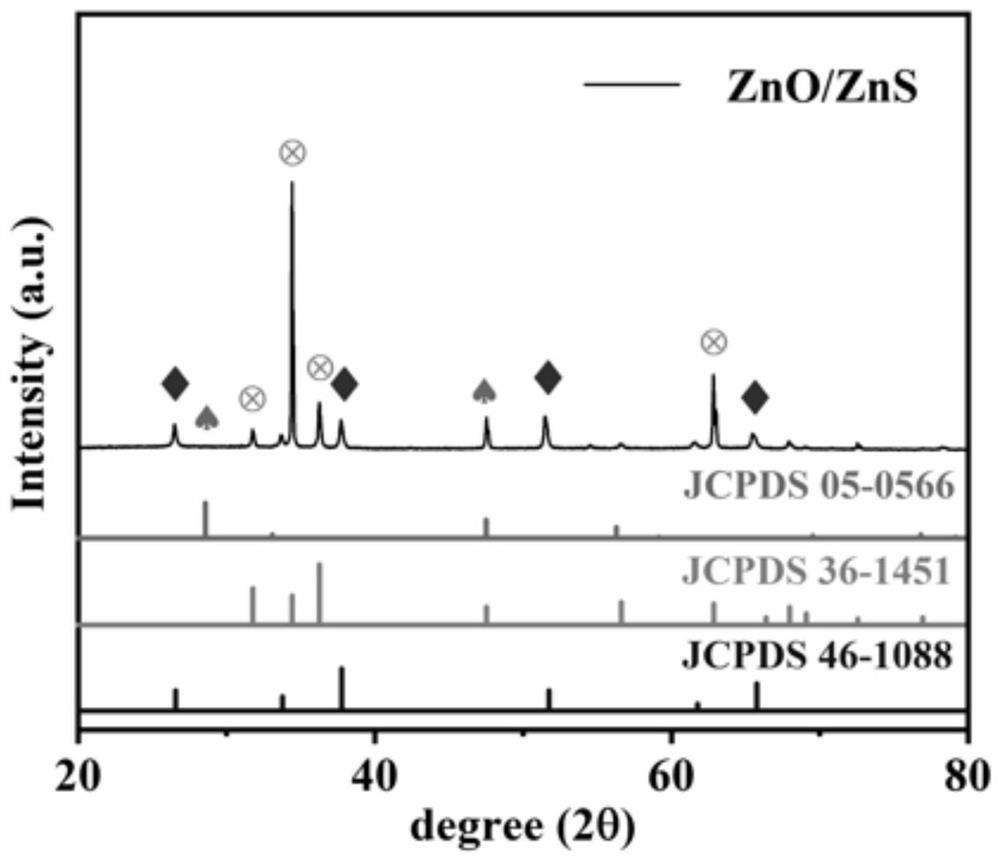

[0046] 1) Scanning electron microscope test and XRD test of photodeposited Au film

[0047] Such as Figure 5 As shown, the gold based on so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com