Method for preparing chlorine through photoelectrocatalysis

A photoelectric catalysis, chlorine gas technology, applied in the direction of electrodes, electrolytic components, electrolysis process, etc., can solve the problems of reducing the production cost of chlorine gas, reducing energy input, wasting energy, etc., to achieve the effect of reducing energy consumption, saving electric energy, and widening the utilization space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1 A kind of photoelectrocatalysis prepares the method for chlorine gas (1) supports titanium dioxide thin film on FTO conductive glass

[0033] The preparation method comprises the following steps:

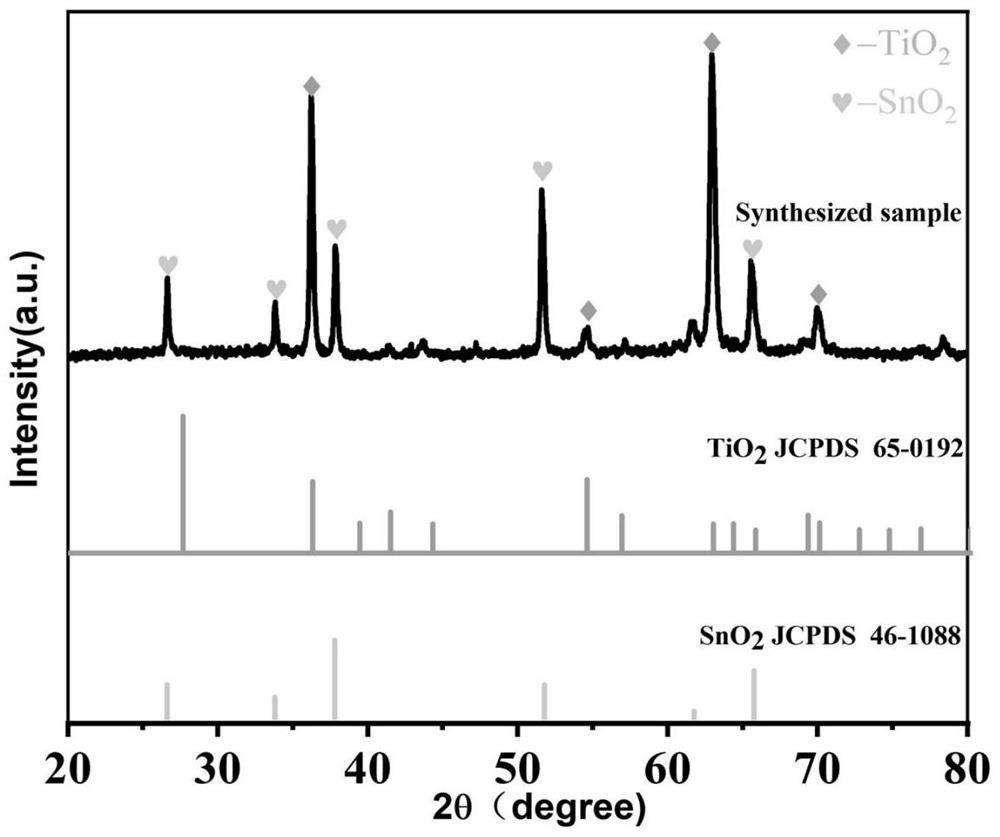

[0034] To prepare titanium dioxide film by hydrothermal method, add 16.5g concentrated hydrochloric acid and 0.6g titanium tetrachloride to 15mL water successively, stir for 15min to make it mix evenly, and obtain solution A; put the cleaned conductive glass (FTO) into the reaction kettle, Then pour the prepared solution A into the reaction kettle, immerse the solution A in the conductive glass, heat and react in an oven at 165°C for 6 hours, take out the conductive glass when it is cooled to 50°C, rinse it with deionized water and dry it naturally, Put it into a muffle furnace and calcinate for 3 hours at a temperature of 550° C. to obtain a conductive glass loaded with a titanium dioxide film.

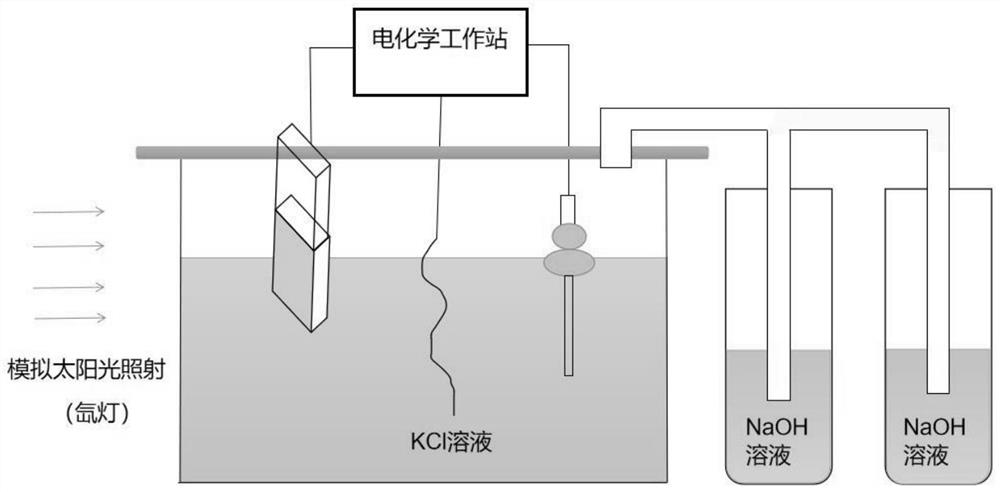

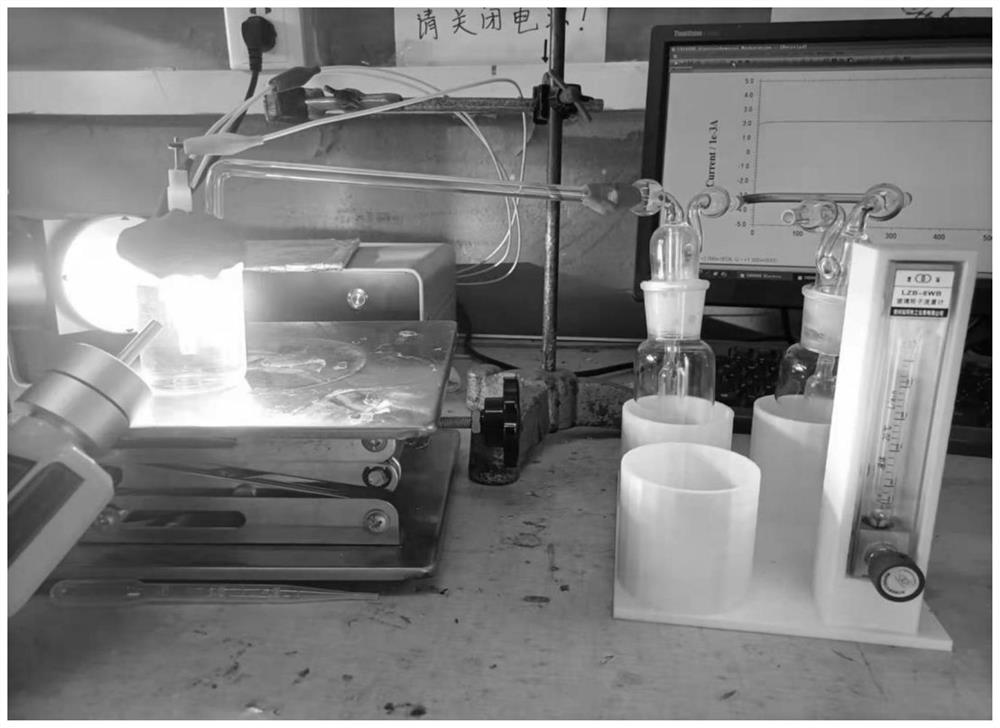

[0035] (2) Photoelectrocatalytic preparation of chlorine gas

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com