Process for producing titanium dioxide through sulfuric acid method as well as titanyl sulfate solution reduction device and method

A technology of titanium dioxide and sulfuric acid method, which is applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of high iron consumption for reduction, increased iron sheet consumption, and long reduction time, and achieves simple equipment, easy implementation, and reduced The effect of the amount of oxygen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

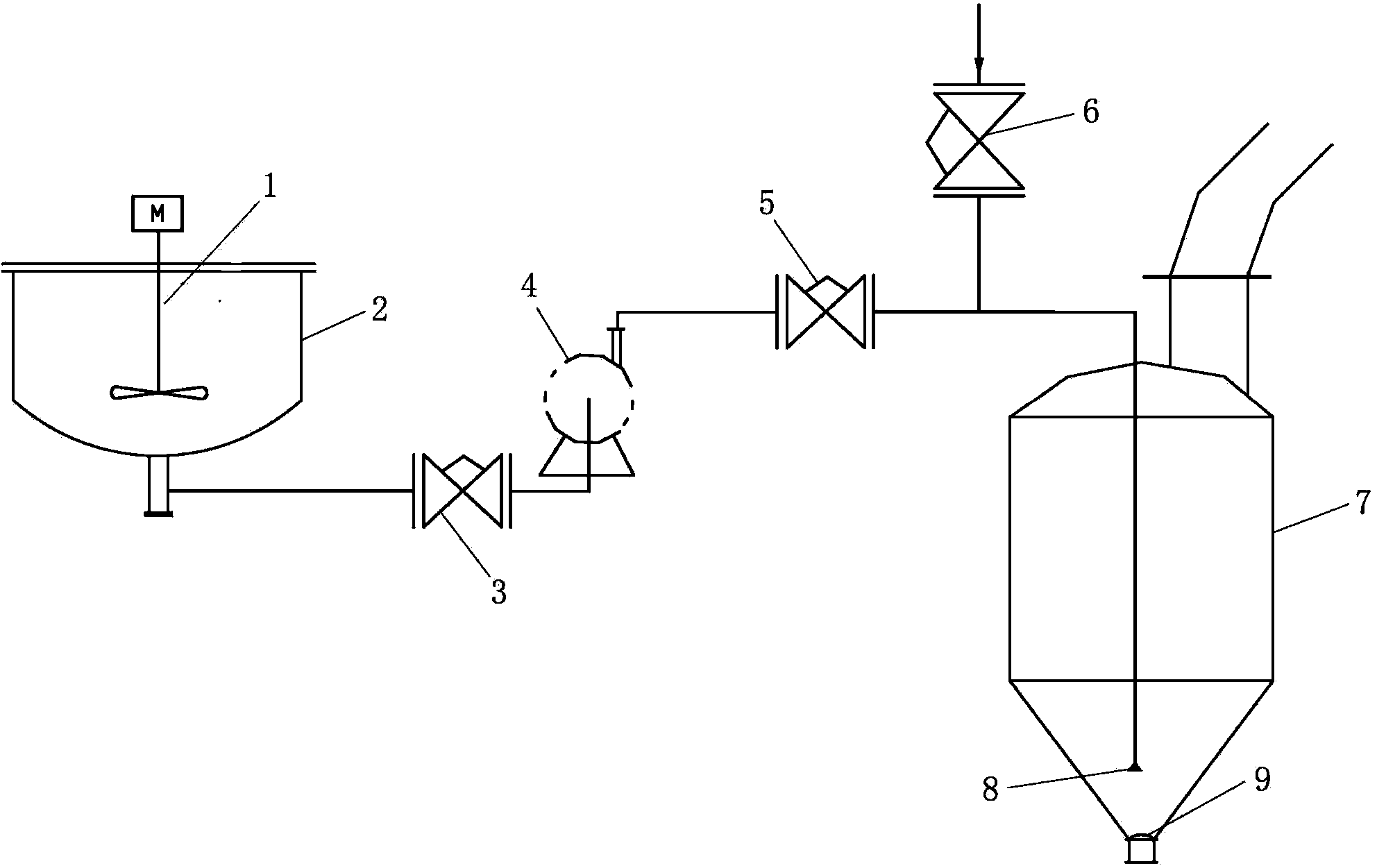

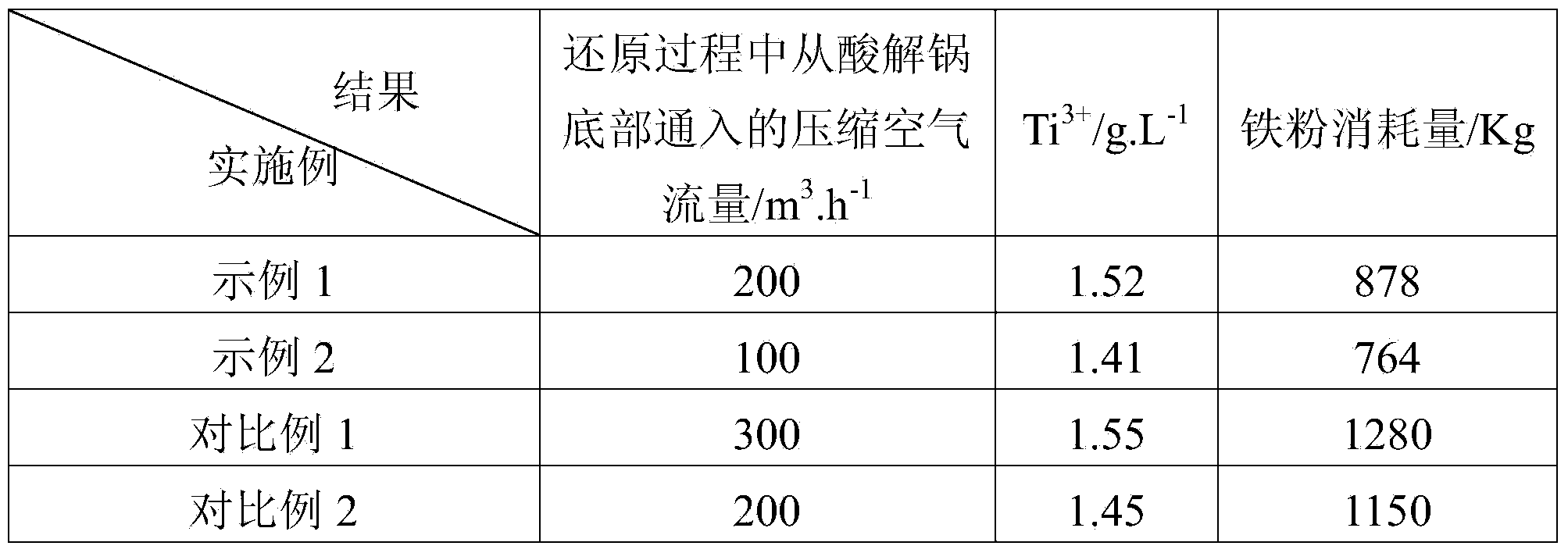

[0035] The volume is 130m 3 28t of titanium concentrates are dropped into the acid hydrolysis pot 7 to react with concentrated sulfuric acid. During the acid hydrolysis and leaching process, the compressed air valve 6 is opened, and the first valve 3 and the second valve 5 are closed to ensure that the pipeline is unblocked. After leaching, close the compressed air valve 6, open the first valve 3 and the second valve 5, and then open the feeding pump 4, and pump the suspension made of iron powder and water in the mixing kettle 2 into the acid Solve the bottom in the pot 7. After the suspension is added, close the feeding pump 4, close the first valve 3 and the second valve 5, and open the compressed air valve 6. At the same time, reduce the flow rate of the compressed air used for stirring from the bottom of the acidolysis pot 7 to 200m 3 / h, keep the acid hydrolysis titanium solution flowing slightly, and the reduction ends after 1.5h.

example 2

[0037] The volume is 130m 3 28t of titanium concentrates are dropped into the acid hydrolysis pot 7 to react with concentrated sulfuric acid. During the acid hydrolysis and leaching process, the compressed air valve 6 is opened, and the first valve 3 and the second valve 5 are closed to ensure that the pipeline is unblocked. After leaching, close the compressed air valve 6, open the first valve 3 and the second valve 5, and then open the feeding pump 4, and pump the suspension made of iron filings and water in the mixing kettle 2 into the acid Solve the bottom in the pot 7. After the suspension is added, close the feeding pump 4, close the first valve 3 and the second valve 5, and open the compressed air valve 6. At the same time, turn down the flow of compressed air for stirring from the bottom of the acidolysis pot 7 to 100m 3 / h, keep the acid hydrolysis titanium solution flowing slightly, and the reduction ends after 1.5h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com