Cast-in-place pile sludge treatment equipment with sludge making and long-distance deslagging functions

A technology for processing equipment and cast-in-place piles, which is used in wellbore/well components, earth-moving drilling, and flushing wellbore. Slag treatment, improving the degree of mechanization, reducing the effect of excess consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with embodiment the present invention is further described.

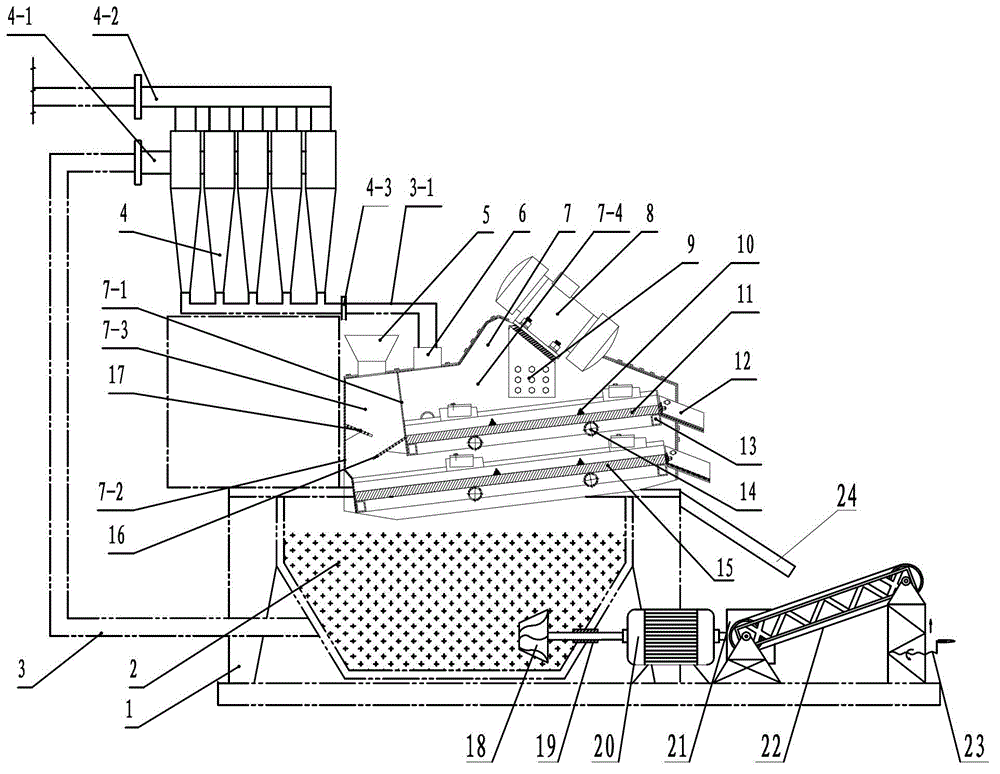

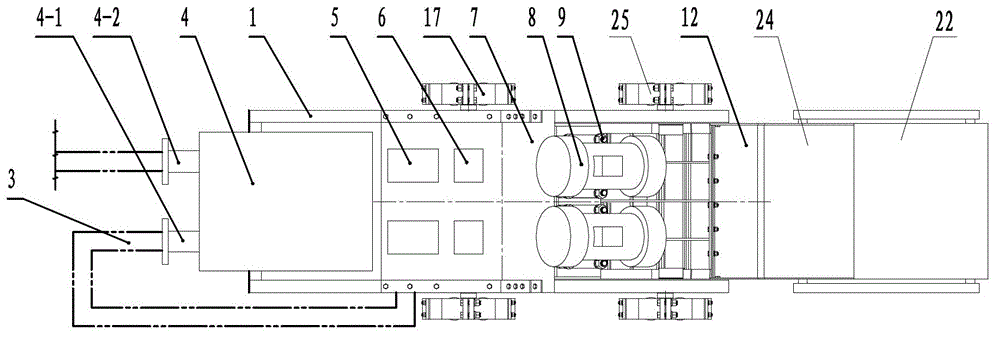

[0015] like figure 1 , figure 2 As shown, a cast-in-situ pile mud treatment equipment with slurry making and remote slag discharge functions, it includes a frame 1, a wedge-shaped screen box 7, a vibration motor 8, a fine screen plate 11, a coarse screen plate 15, a slurry tank 2 and a rotary flow device unit 4; the two sides of the wedge-shaped screen box 7 are installed on the frame 1 through four groups of shock absorbers 25; There are two groups of vibrating motors 8, and the two groups of vibrating motors 8 are installed side by side on the upper end of the wedge-shaped screen box 7 through the motor base 9; In the inner cavity of the screen box 7, the lower parts of the fine and coarse sieve plates 11 and 15 are supported by a sieve plate beam 14; the discharge ends of the fine and coarse sieve plates 11 and 15 are connected to the discharge chute 12; The sieve plate frame 13 su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com