Asphalt high-temperature cleaning machine for test pipe bottle

A washing machine and experimental technology, which is applied in the field of washing machines, can solve the problems of difficult asphalt cleaning, slow cleaning speed, waste of resources, etc., and achieve the effect of fast cleaning, improved cleaning efficiency, and improved cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

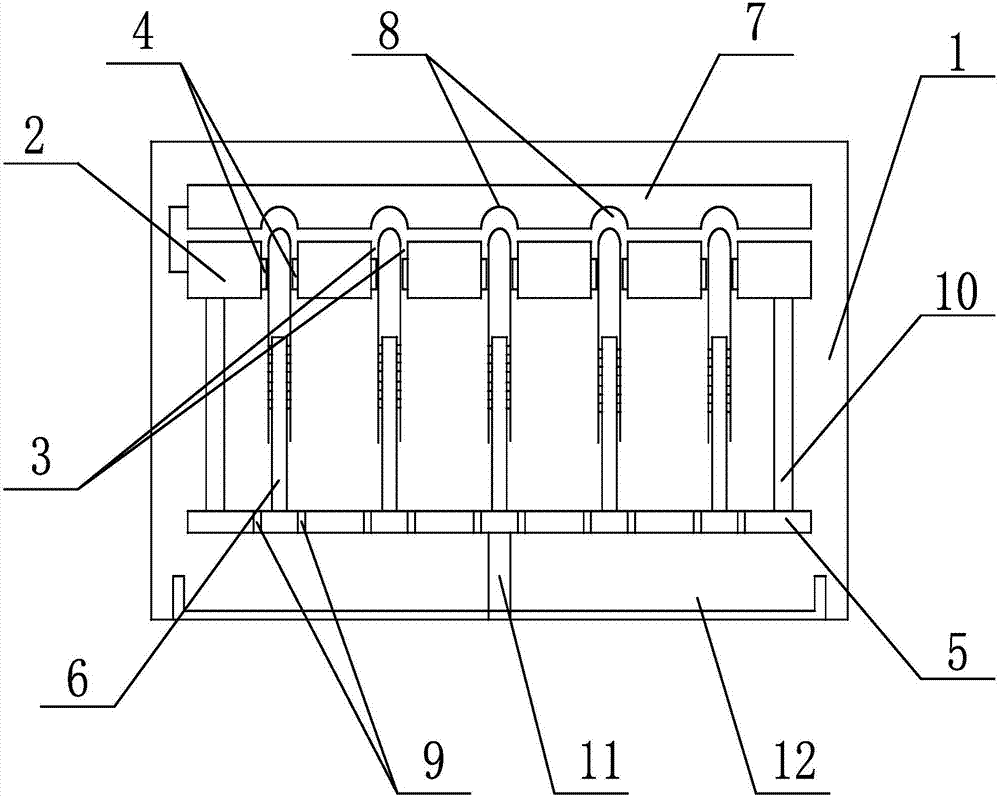

[0023] Such as figure 1 As shown, the present invention is used for the asphalt high-temperature cleaning machine of experimental tube bottle, comprises cleaning box body 1, and cleaning box body 1 is provided with test tube placement plate 2, is provided with a plurality of test tube insertion holes 3 on the test tube placement plate 2, The inner wall of the test tube jack 3 is provided with a fixed slider 4, and the fixed slider 4 slides up and down on the inner wall of the test tube jack 3; A vertically arranged self-rotation cleaning nozzle 6, the self-rotation cleaning nozzle 6 is located directly below the test tube jack 3; a test tube heating plate 7 is provided above the test tube placement plate 2, and a test tube heating plate 7 is provided on the bottom surface of the test tube heating plate 7 There are a plurality of upwardly convex heating grooves 8 , heating wires are arranged in the heating grooves 8 , and the heating grooves 8 are located directly above the tes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com