Preparation method of quick setting and rapid hardening gangue alkali-activated rapid repairing material

A technology for repairing materials and coal gangue, which is applied in the field of preparation of fast-setting and fast-setting hard coal gangue alkali-induced fast-repairing materials, can solve the problems of insufficient early strength, shortened setting time, slow setting, etc., and achieves acceleration of setting time and elimination of environmental pollution. Problem, effect of high cohesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

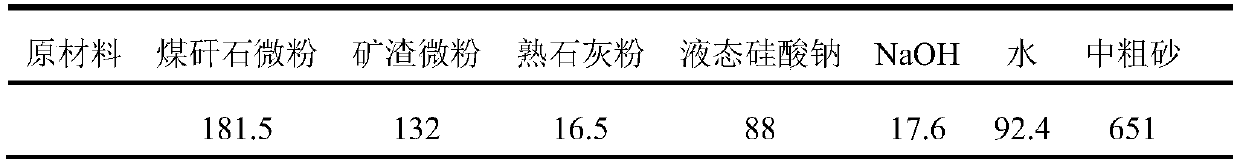

[0025] Embodiment 1: A kind of fast-setting fast-hardening coal gangue alkali-activated rapid repair material, raw material composition and mass percentage thereof are as follows: the cementitious material is ground coal gangue micropowder 55% (dosage 181.5kg / m 3 ); blast furnace granulated slag powder 40% (dosage 132kg / m 3 ); ground slaked lime powder 5% (dosage 16.5kg / m 3 ); the fine aggregate is medium-coarse sand (dosage 651kg / m 3 ); the activator is liquid sodium silicate with a modulus of 2.75 (dosage 88kg / m 3 ); caustic soda (NaOH dosage 17.6kg / m 3 ); water (amount 92.4kg / m 3 );

[0026] Table 1 Test mix ratio kg / m 3

[0027]

[0028] Using the above-mentioned fast-setting and fast-hardening coal gangue alkali-activated fast repairing material: its preparation process includes weighing ingredients and mixing process, preparation process and pouring process, and the specific methods are as follows:

[0029](1) Weighing batching and mixing process: first, accord...

Embodiment 2

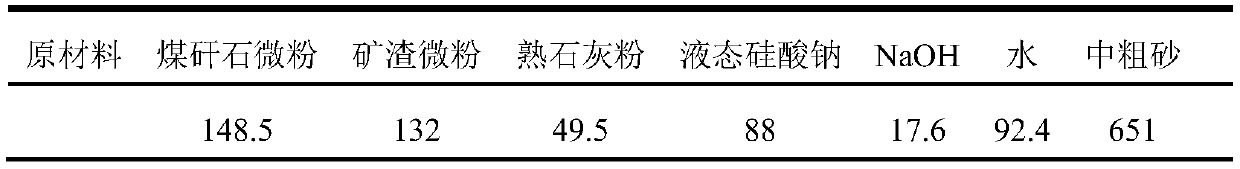

[0032] Embodiment 2: preparation method is identical with embodiment 1, omission. The difference is that: a fast-setting fast-hardening coal gangue alkali-activated rapid repair material, the raw material composition and its mass percentage are as follows: the cementitious material is 45% of finely ground coal gangue powder (amount of 148.5kg / m 3 ); blast furnace granulated slag powder 40% (dosage 132kg / m 3 ); ground slaked lime powder 15% (dosage 49.5kg / m 3 ); the fine aggregate is medium-coarse sand (dosage 651kg / m 3 ); the activator is liquid sodium silicate with a modulus of 2.75 (dosage 88kg / m 3 ); caustic soda (NaOH dosage 17.6kg / m 3 ); water (amount 92.4kg / m 3 );

[0033] Table 2 Test mix ratio kg / m 3

[0034]

Embodiment 3

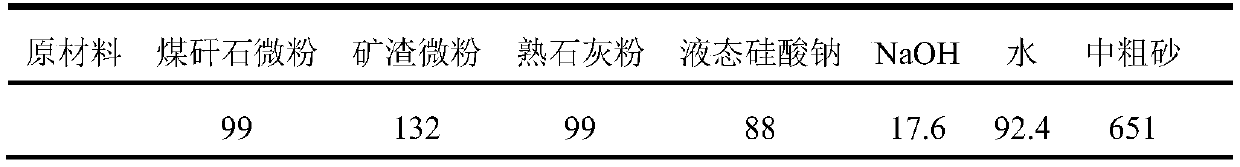

[0035] Embodiment 3: preparation method is identical with embodiment 1, omission. The difference is: a fast-setting and fast-hardening coal gangue alkali-activated rapid repair material, the raw material composition and its mass percentage are as follows: the cementitious material is 30% of finely ground coal gangue powder (amount of 181.5kg / m 3 ); blast furnace granulated slag powder 40% (dosage 132kg / m 3 ); ground slaked lime powder 30% (dosage 16.5kg / m 3 ); the fine aggregate is medium-coarse sand (dosage 651kg / m 3 ); the activator is liquid sodium silicate with a modulus of 2.75 (dosage 88kg / m 3 ); caustic soda (NaOH dosage 17.6kg / m 3 ); water (amount 92.4kg / m 3 );

[0036] Table 3 Test mix ratio kg / m 3

[0037]

[0038] The setting time and compressive strength of coal gangue alkali-activated quick repair materials were measured as follows: Table 4 shows.

[0039] Table 4 Coagulation time and compressive strength of coal gangue alkali-activated rapid repair ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| flame retardant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com