Oil casing pipe resisting CO2 corrosion and production method thereof

A production method and oil-casing technology, which is applied in the direction of casing, drill pipe, earthwork drilling, etc., can solve the problems of low hardness of the coating, easy peeling of the coating, short service life, etc., and achieve high microhardness, economical Good performance, good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

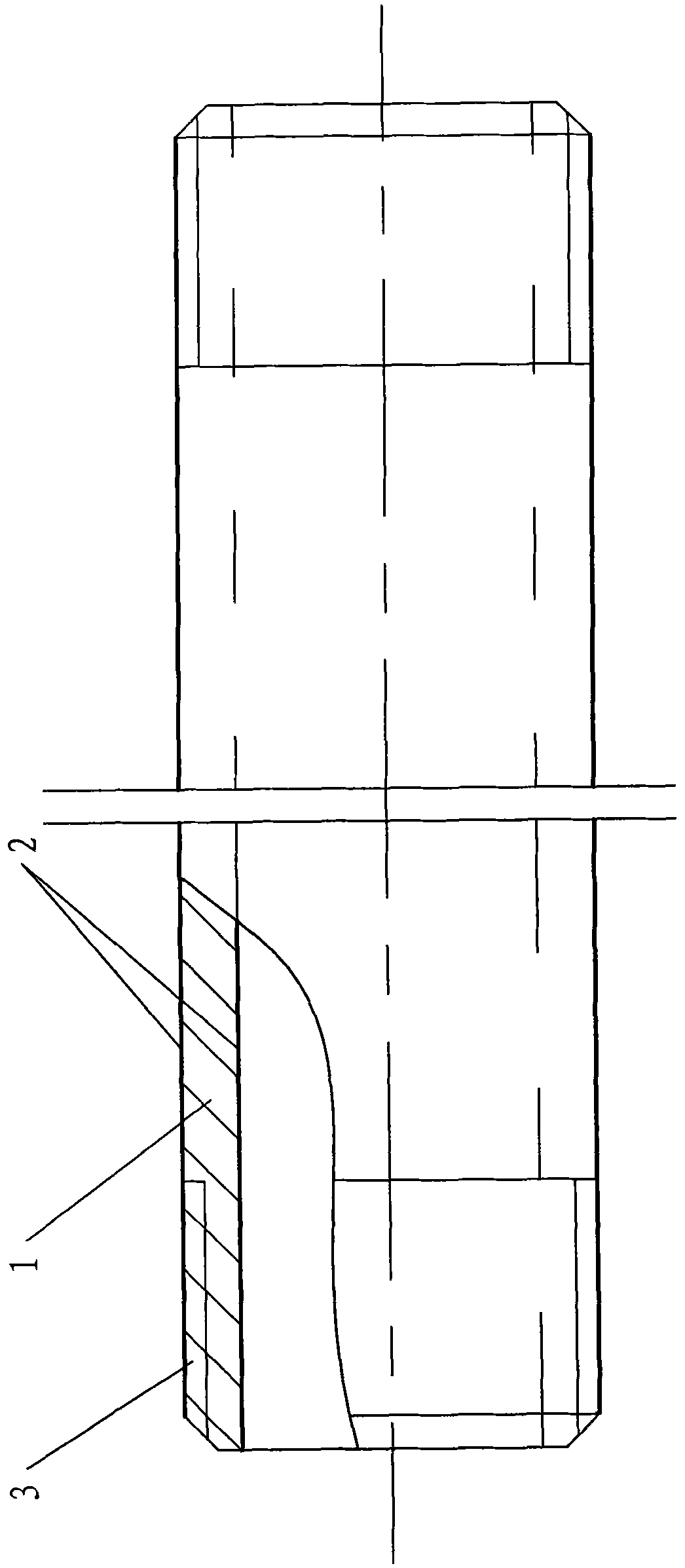

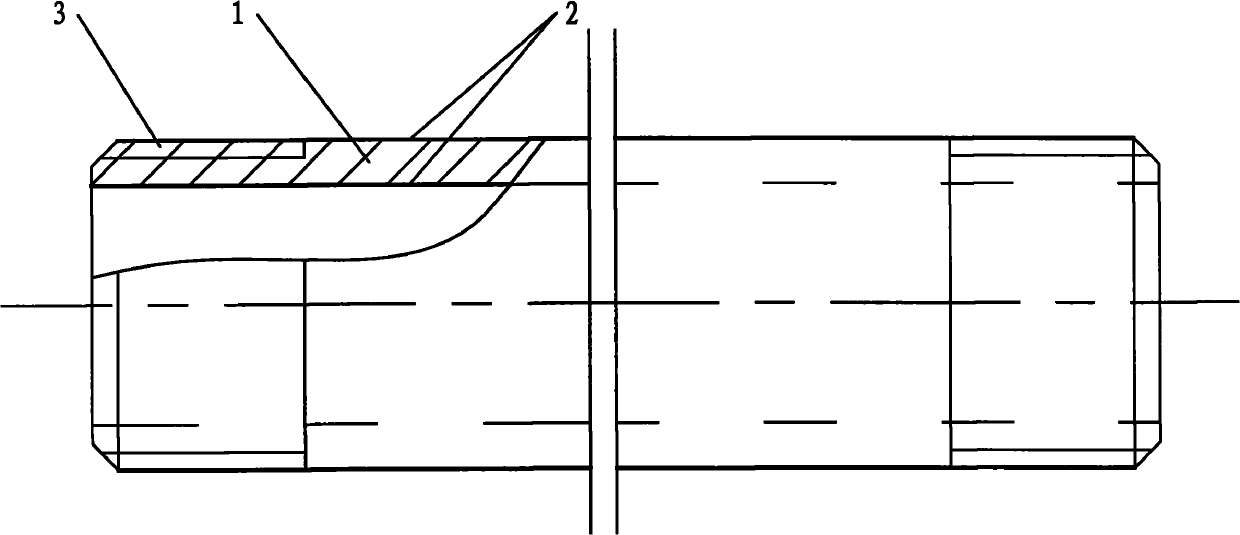

Image

Examples

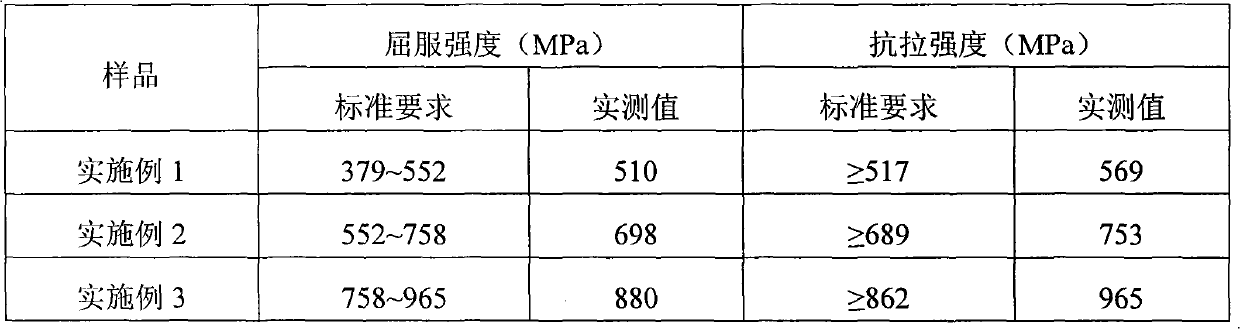

Embodiment 1

[0022] Produce the anti-CO of the present invention according to the following steps 2 Corrosion oil casing:

[0023] (1) Use J55 steel commonly used for oil and casing in API to process the tubular base of the oil casing, and process the external thread parts at both ends.

[0024] (2) Carry out electrolytic degreasing treatment on the tubular substrate, and pass 8A / cm2 into the degreasing liquid at 50°C 3 The electric current, and keep warm for 8 minutes, the composition of degreasing liquid is: 0.7mol / L NaOH, 0.4mol / L NaOH 2 CO 3 , 0.25mol / L of Na 2 SiO 3 ; Use deionized water to clean and remove the degreasing liquid on the tubular substrate after the degreasing treatment, and then use the compressed air sandblasting method to carry out derusting treatment on the tubular substrate, and the sand particle size is 20 mesh.

[0025] (3) The sodium nitrate activation process is used to activate the above-mentioned tubular substrate, so that the fresh metal layer is exposed...

Embodiment 2

[0030] Produce the anti-CO of the present invention according to the following steps 2 Corrosion oil casing:

[0031] (1) The tubular base of the oil casing is processed by using API common oil casing steel N80, and the external thread part is processed at both ends.

[0032] (2) Carry out electrolytic degreasing treatment on the tubular substrate, and pass 10A / cm2 into the degreasing liquid at 70°C 3 current, and keep warm for 7 minutes, the composition of degreasing liquid is: 1.0mol / L NaOH, 0.3mol / L NaOH 2 CO 3 , 0.08mol / L of Na 2 SiO 3 ; Use deionized water to clean and remove the degreasing liquid on the tubular substrate after degreasing treatment, and then use compressed air sandblasting method to carry out derusting treatment on the tubular substrate, and the sand particle size is 40 mesh.

[0033] (3) The sodium nitrate activation process is used to activate the above-mentioned tubular substrate, so that the fresh metal layer is exposed on the surface of the tubu...

Embodiment 3

[0038] Produce the anti-CO of the present invention according to the following steps 2Corrosion oil casing:

[0039] (1) Use API common oil casing steel P110 to process the tubular base of the oil casing, and process the external thread parts at both ends.

[0040] (2) Carry out electrolytic degreasing treatment on the tubular substrate, and pass 5A / cm2 into the degreasing liquid at 80°C 3 current, and keep warm for 5min, the composition of degreasing liquid is: 1.2mol / L NaOH, 0.5mol / L NaOH 2 CO 3 , 0.18mol / L of Na 2 SiO 3 ; Use deionized water to clean and remove the degreasing liquid on the tubular substrate after the degreasing treatment, and then use the compressed air sandblasting method to carry out derusting treatment on the tubular substrate, and the sand particle size is 30 mesh.

[0041] (3) The sodium nitrate activation process is used to activate the above-mentioned tubular substrate, so that the fresh metal layer is exposed on the surface of the tubular subst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com