Method for fully utilizing gold tailings

A technology of gold tailings and tailings, applied in chemical instruments and methods, wet separation, magnetic separation, etc., can solve the problems of incomplete utilization of tailings, incomplete classification, waste of resources, etc., and achieve high hardness and poor thermal conductivity , good temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

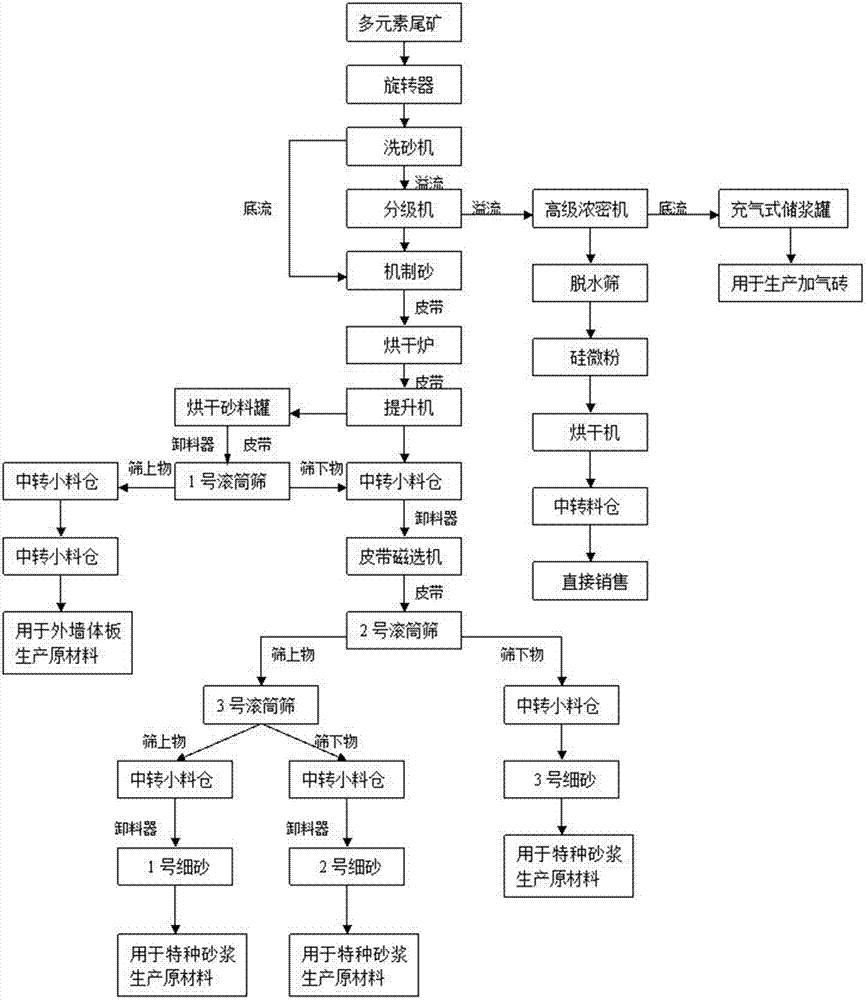

[0022] Such as figure 1 Shown, the present invention is a kind of method that fully utilizes gold tailings, mainly comprises the following steps:

[0023] (1) The tailings of the multi-element workshop enter the cyclone, and the tailings with large and small specific gravity are separated, and the separated materials with small specific gravity after being classified by the cyclone enter the sand washing machine, and after sand washing The screen of the sand washing machine is divided into an underflow part and an overflow part after being screened, and the underflow part of the sand washing machine is the machine-made sand;

[0024] (2) As in step (1), the overflow part screened by the sand washing machine enters the classifier for further classification, and the part with a smaller specific gravity overflows out and enters the next process flow. After screening by the classifier The underflow part becomes machine-made sand.

[0025] The overflow part of the classifier in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com