Wet base surface treating agent

A base treatment agent and base surface technology, applied in the field of wet base surface base treatment agent, can solve problems such as not reaching the ideal state, achieve excellent anti-stripping ability, wide source, and increase the effect of crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Proportion (weight ratio, the same below) of the A-component raw materials in the wet base surface treatment agent of the product according to the following (Table 1):

[0038] Table 1 Formula list of component A of wet base surface treatment agent

[0039]

[0040] The manufacturing process of component A of wet base surface treatment agent is as follows: add emulsified asphalt, modified emulsion, and additives to the mixing tank, stir at medium speed for 20 minutes, filter after standing for 1 hour, and pack.

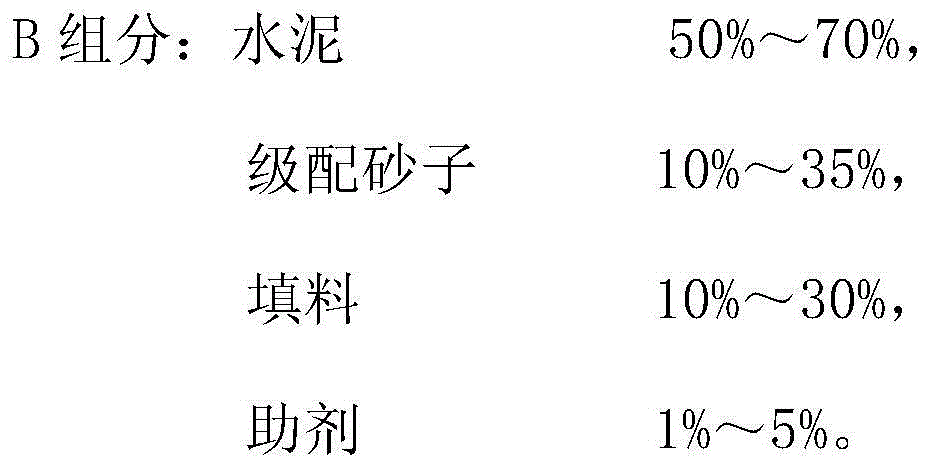

[0041] Then the B component in the product is carried out proportioning (weight ratio, hereinafter the same) according to the following (table 2):

[0042] Table 2 Formula list of component B of wet base surface treatment agent

[0043] cement

filler 1

Graded sand

Auxiliary

gray cement

Graded sand

50

18

30

2

[0044] The manufacturing process of component ...

Embodiment 2

[0048] Proportion (weight ratio, the same below) of the A component raw materials in the wet base surface treatment agent of the product according to the following (Table 4):

[0049] Table 4 Formula list of component A of wet base surface treatment agent

[0050]

[0051] The manufacturing process of component A of wet base surface treatment agent: the difference from Example 1 is only that the amount of each raw material is added according to Table 4.

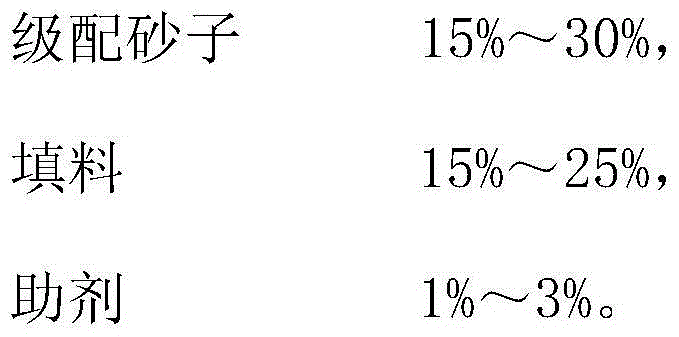

[0052] The B component in the product is carried out proportioning (weight ratio, the same below) as follows (Table 5):

[0053] Table 5 Formula table of component B of wet base surface treatment agent

[0054] cement

Graded sand

filler 2

Auxiliary

White cement

Graded sand

59

28

10

3

[0055] Manufacture process of component B of wet base surface treatment agent: The difference from Example 1 is only that the amount of ...

Embodiment 3

[0060] Proportion (weight ratio, the same below) of the raw materials of component A in the wet base surface treatment agent of the product according to the following (Table 7):

[0061] Table 7 Formula list of component A of wet base surface treatment agent

[0062]

[0063]

[0064] The manufacturing process of component A of wet base surface treatment agent: the difference from Example 1 is only that the amount of each raw material is added according to Table 7.

[0065] The B component in the product is carried out proportioning (weight ratio, the same below) as follows (Table 8):

[0066] Table 8 Formula table of component B of wet base surface treatment agent

[0067] cement

Graded sand

filler 2

Auxiliary

White cement

Graded sand

59

28

10

3

[0068] Manufacture process of component B of wet base surface treatment agent: The difference from Example 1 is only that the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| tack-free time | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com