Novel Ball-ring, and process for making same

A new type of hollow technology, applied in chemical/physical/physicochemical processes, chemical instruments and methods, chemical/physical processes, etc., to achieve the effects of reducing production costs, not easy to break and melt, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

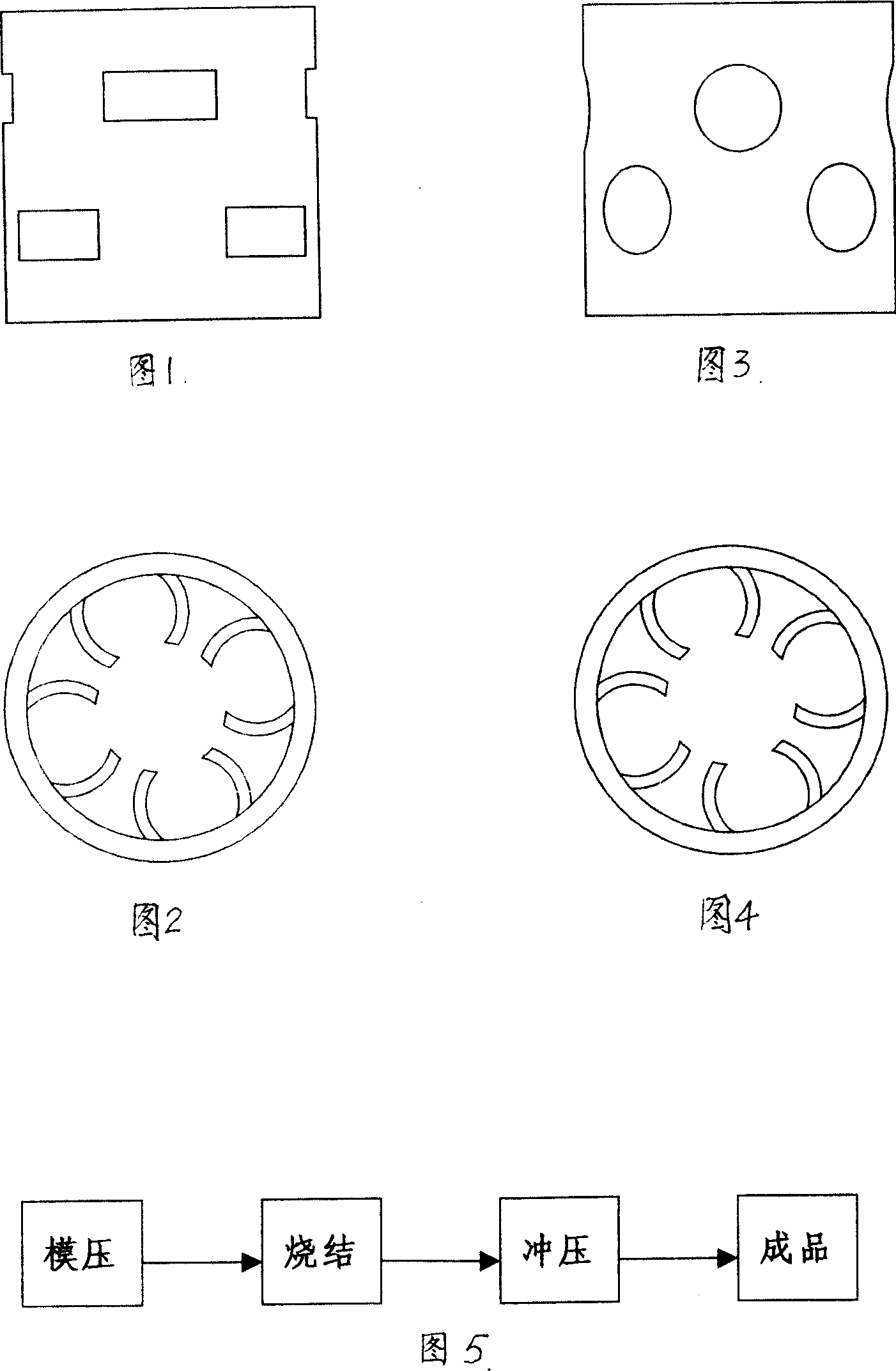

[0014] Combined with Figure 1, Figure 2, Figure 3, and Figure 4, a hollow cylinder with equal height and diameter is made by using polytetrafluoroethylene powder material through molding and post-processing. There are four tongues on the inner wall next to each layer of window holes, and each tongue is bent inward to point to the center of the column. The positions of the two layers of windows and tongues are opposite and staggered. New Pall ring.

[0015] With reference to Fig. 3, the manufacturing process flow of the present invention is: molding, sintering, stamping. The specific production process is as follows:

[0016] 1. Molding: the basic structure of the present invention is formed by molding. The whole mold combination is composed of three parts: outer jacket, inner jacket and mold core. First, use 2 mold cores, one right-handed and one left-handed, and the cross blades are connected together with screws, install the inner sleeve of the material, and then the outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com