Special film based treatment process for waste incineration plant leachate

A technology of waste incineration and treatment process, which is applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, etc. and other problems, to achieve a wide range of application prospects, improve service life, and good system stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

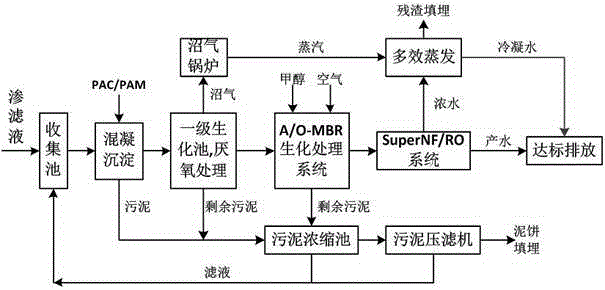

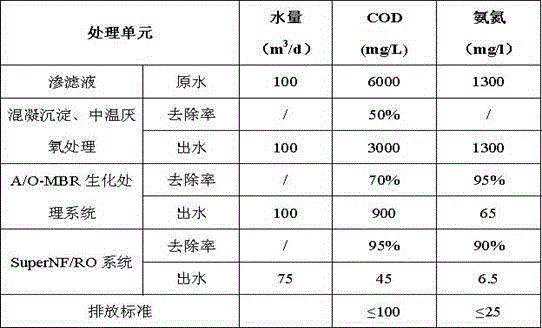

[0032] Such as figure 1 As shown, the leachate treatment process of waste incineration plant based on special membrane includes the following steps:

[0033] (1) Introduce landfill leachate into the collection tank;

[0034] (2) Add flocculants to pretreat the liquid with coagulation and sedimentation to remove suspended particles in the leachate, and the sludge generated by sedimentation enters the sludge thickening tank; among them, the added flocculants are at least polyaluminum chloride PAC, One of polyacrylamide PAM;

[0035] (3) The effluent after pretreatment enters the primary biochemical tank for anaerobic treatment through anaerobic microorganisms to remove most of the organic pollutants, the generated sludge enters the sludge thickening tank, and the biogas produced by anaerobic microorganisms is discharged into the biogas boiler; Among them, the temperature is controlled at 30-35°C, which can achieve the effect of COD removal rate of 50%;

[0036] (4) The efflu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com