Hinge filtering component and filtering system

A filter component and filter layer technology, which is applied in the direction of filter separation, fixed filter element filter, semi-permeable membrane separation, etc., can solve the problems of difficult sealing process at both ends of the filter component, affecting filtration efficiency, low filtration efficiency, etc., to achieve High loading density, increased filter area and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

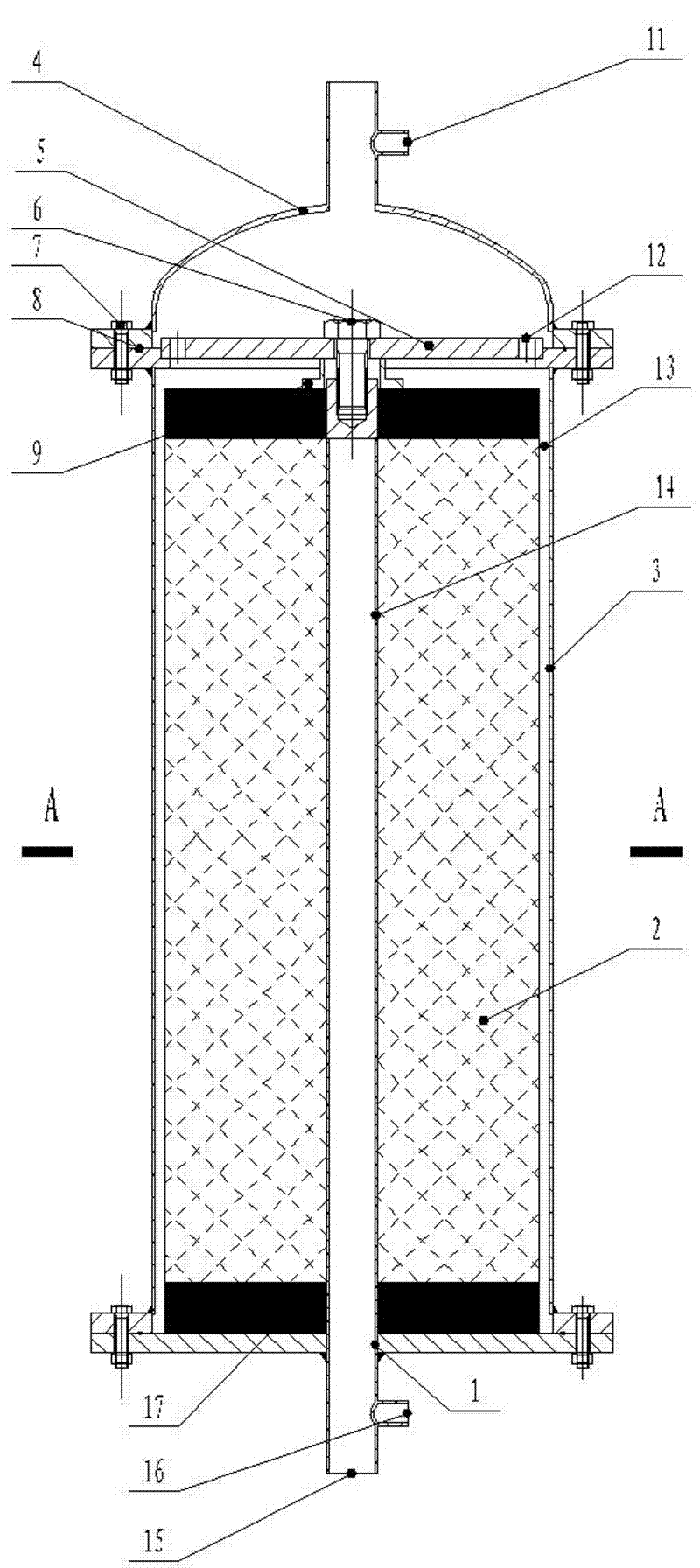

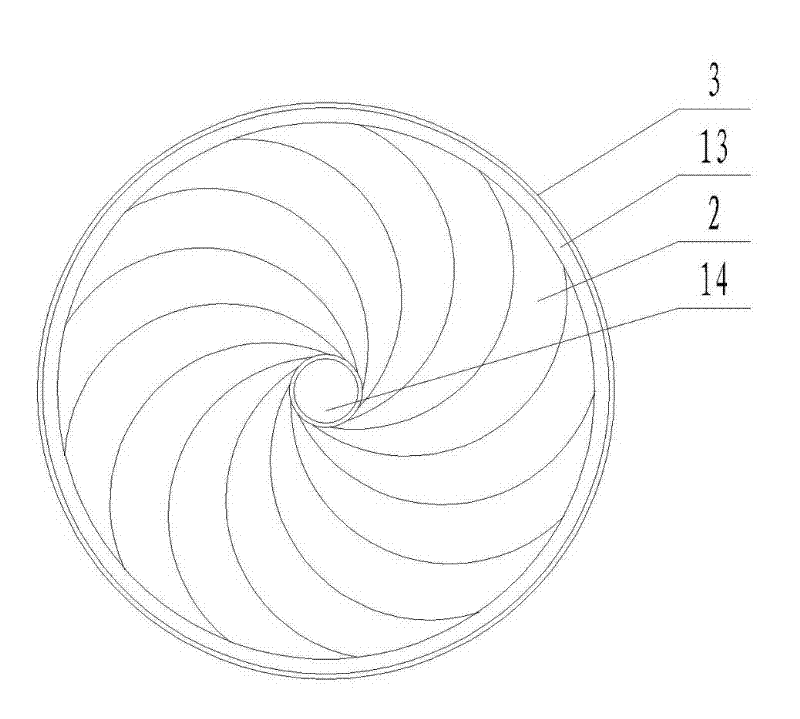

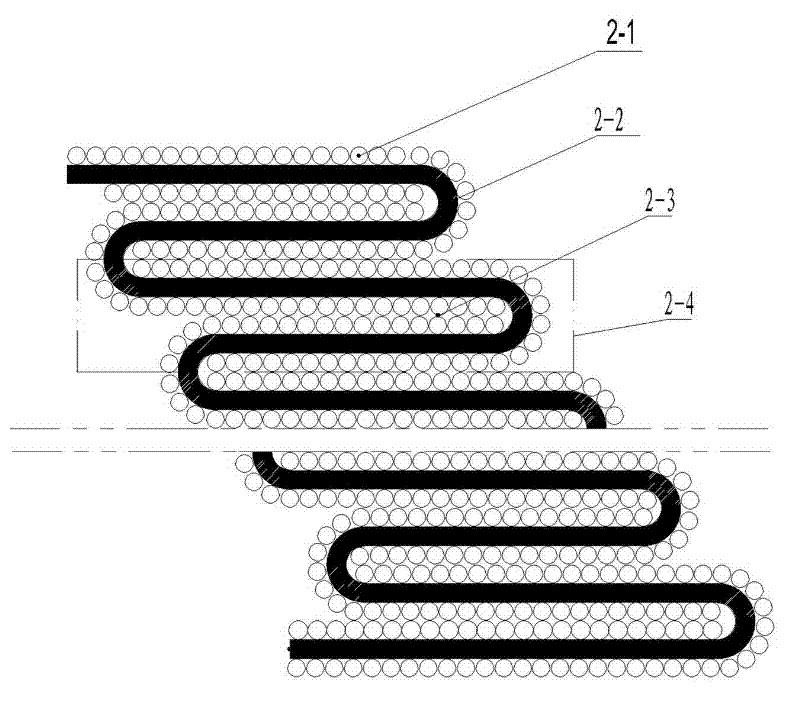

[0041] Such as figure 1 A hinged filter assembly is shown, which includes an inner cylinder 1, a filter layer 2, an outer cylinder 3, a head 4, a water diversion baffle 5, a fastening bolt 6, a sealing bolt 7, a sealing ring 8, a retaining Circle 9, water inlet and outlet I10, air inlet I11, flow hole 12, water flow channel 13, inner pipe water hole 14, water inlet and outlet II15, air inlet II16 and sealing tape 17.

[0042] The inner cylinder 1 is arranged in the outer cylinder 3, and the inner cylinder 1 and the outer cylinder 3 are arranged coaxially. The inner cylinder 1 can be made of a section of pipe, and the upper end of the outer cylinder 3 and the head 4 pass through flanges and sealing rings. 8 and the sealing bolt 7 are sealed and connected, and the upper port of the outer cylinder 3 is provided with a water diversion baffle 5, and a plurality of water flow holes 12 are arranged on the water diversion baffle 5, and a blind plate is welded on the upper end of the i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com