Spiral runner type sewage heat exchanger

A spiral flow channel and heat exchanger technology, applied in the direction of heat exchanger type, heat exchanger shell, indirect heat exchanger, etc., can solve the problems of increased sewage flow resistance, small flow resistance, easy fouling, etc., to achieve flow Smooth, small flow resistance, not easy to fouling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

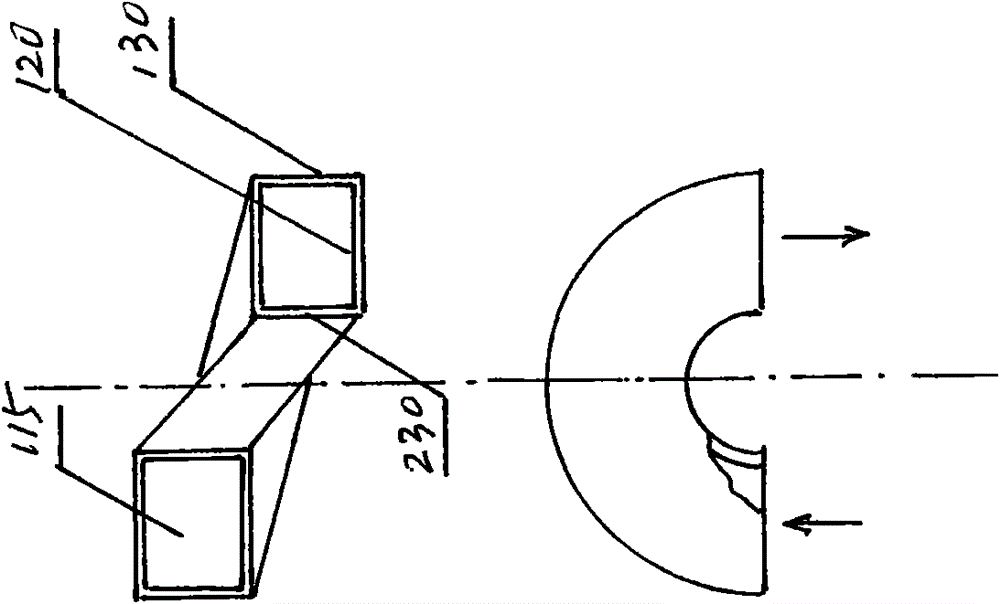

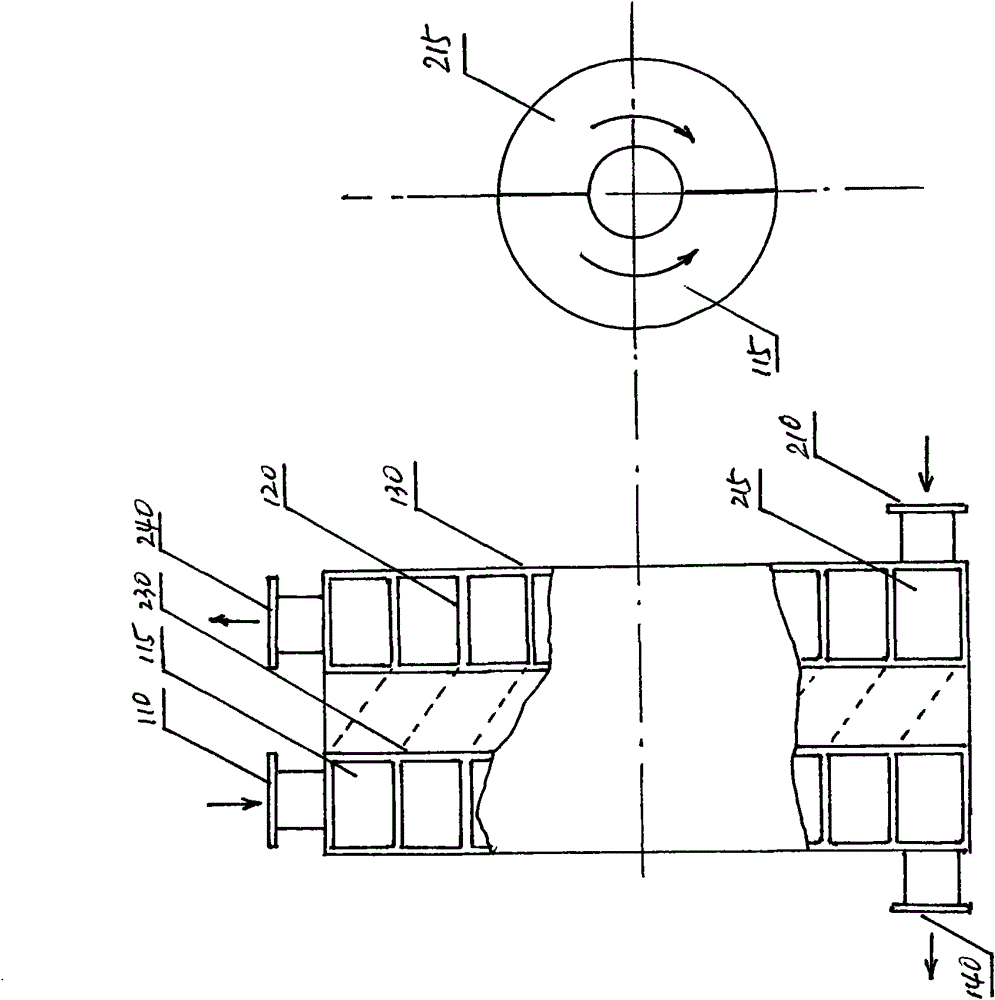

[0025] figure 1 The basic principle diagram of the embodiment of the spiral channel type sewage heat exchanger of the present invention is given.

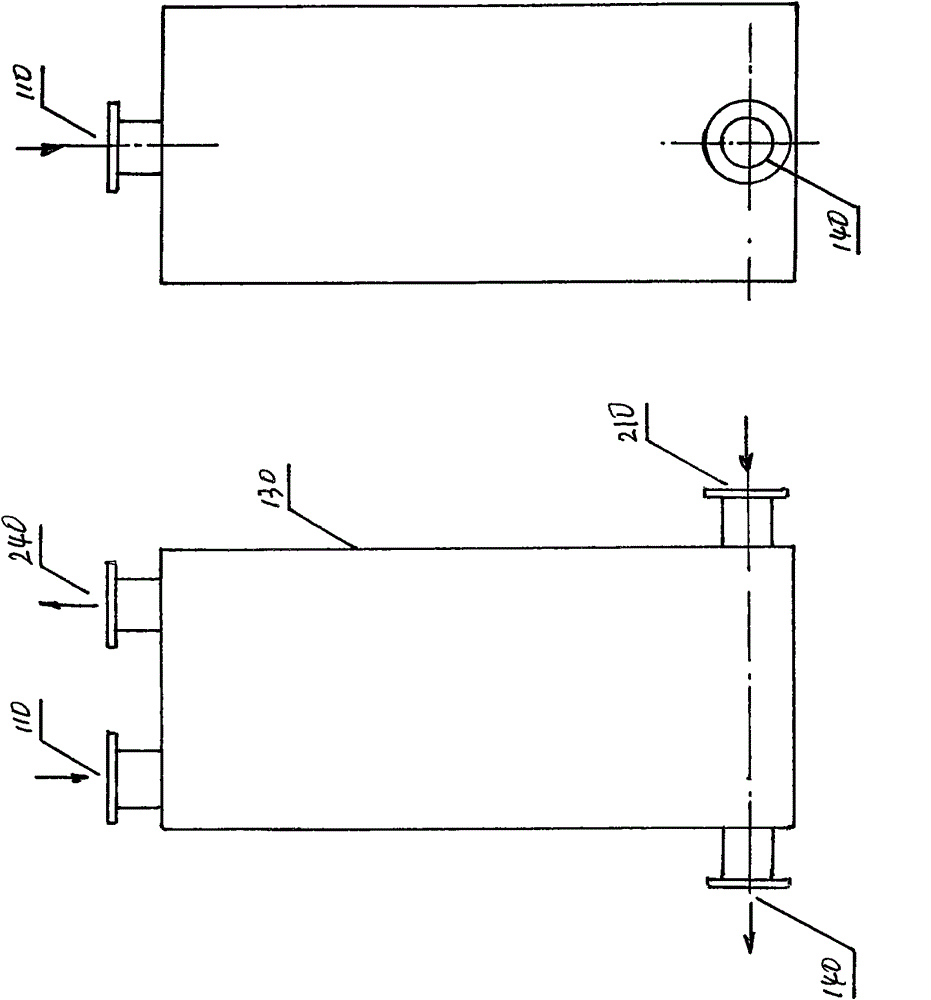

[0026] The basic principle of the embodiment of the spiral channel type sewage heat exchanger of the present invention is as follows: figure 1 shown. The sewage pipe 115 is in a spiral shape, similar to a threaded cylindrical spiral. The sewage pipe 115 rotates along a fixed radius around a vertical central axis. While the sewage channel is rotating, it is still reducing the height. Every time the sewage channel turns around in the horizontal direction, it will drop a pitch in the vertical direction. The cross-section of the sewage pipe 115 is a rectangle, the upper and lower sides of this rectangle are partition walls 120 , one vertical side thereof is the inner wall 230 of the sewage flow ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com