Cement rotary kiln barrel radiation, reclaiming and utilizing device

A cement rotary kiln and rotary kiln technology, which is applied in the field of recovery and utilization of heat from the rotary kiln cylinder used for cement calcination, can solve the problem of low waste heat utilization efficiency, and achieve the effects of strong practicability, energy saving and obvious economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

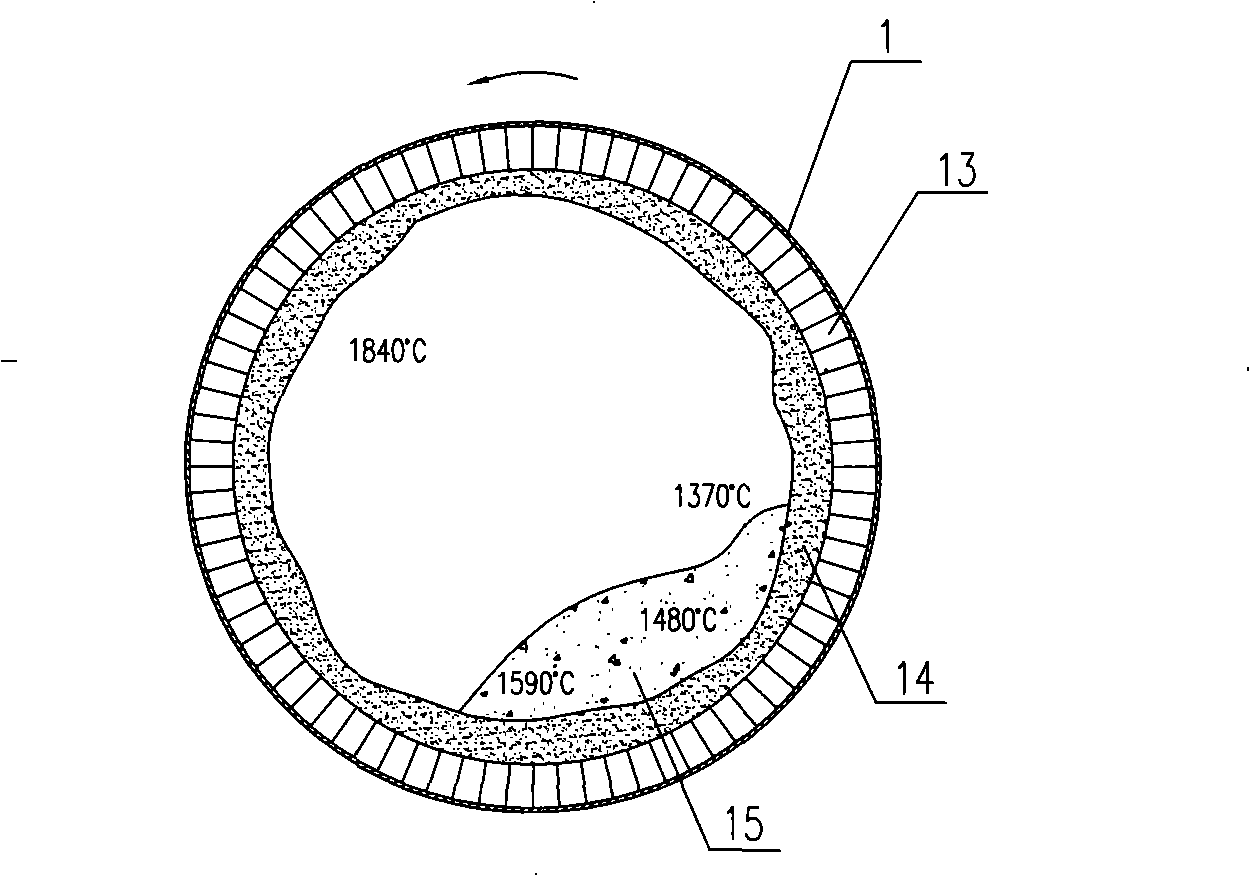

[0033]Use demineralized water or demineralized water as the heat exchange medium, and directly produce low-temperature and low-pressure (0.2-0.3Mpa, 150-170°C) steam with a certain degree of superheat after passing through the heat exchange cover. The steam is used as pure low-temperature waste heat power generation in cement plants. The supplementary steam enters the supplementary steam port of the steam turbine to drive the turbine to rotate and drive the generator to generate electricity; or all produce low-temperature and low-pressure saturated steam, which enters the low-temperature and low-pressure steam section of the pure low-temperature waste heat power generation boiler in the cement plant, and is used for power generation after being superheated by the boiler. The production of low-temperature and low-pressure steam in the heat exchange chamber is allowed by the strength of the rotary kiln shell.

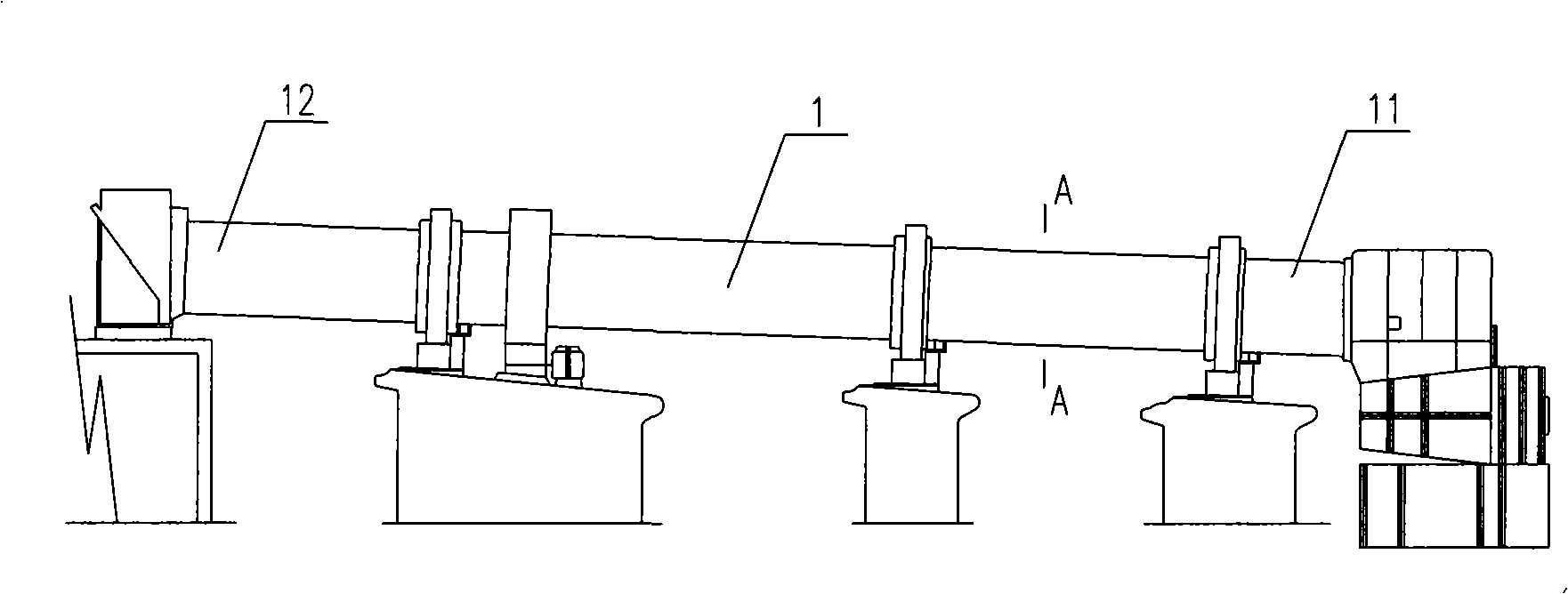

[0034] The cement rotary kiln shell heat dissipation recycling device...

Embodiment 2

[0046] In this embodiment, the heat transfer oil is used as the heat exchange medium, and the heat transfer hood is used to exchange heat on the surface of the rotary kiln shell through the heat transfer oil in the form of forced circulation. The heat transfer oil after heat exchange is directly introduced to the energy conversion device for heating and so on.

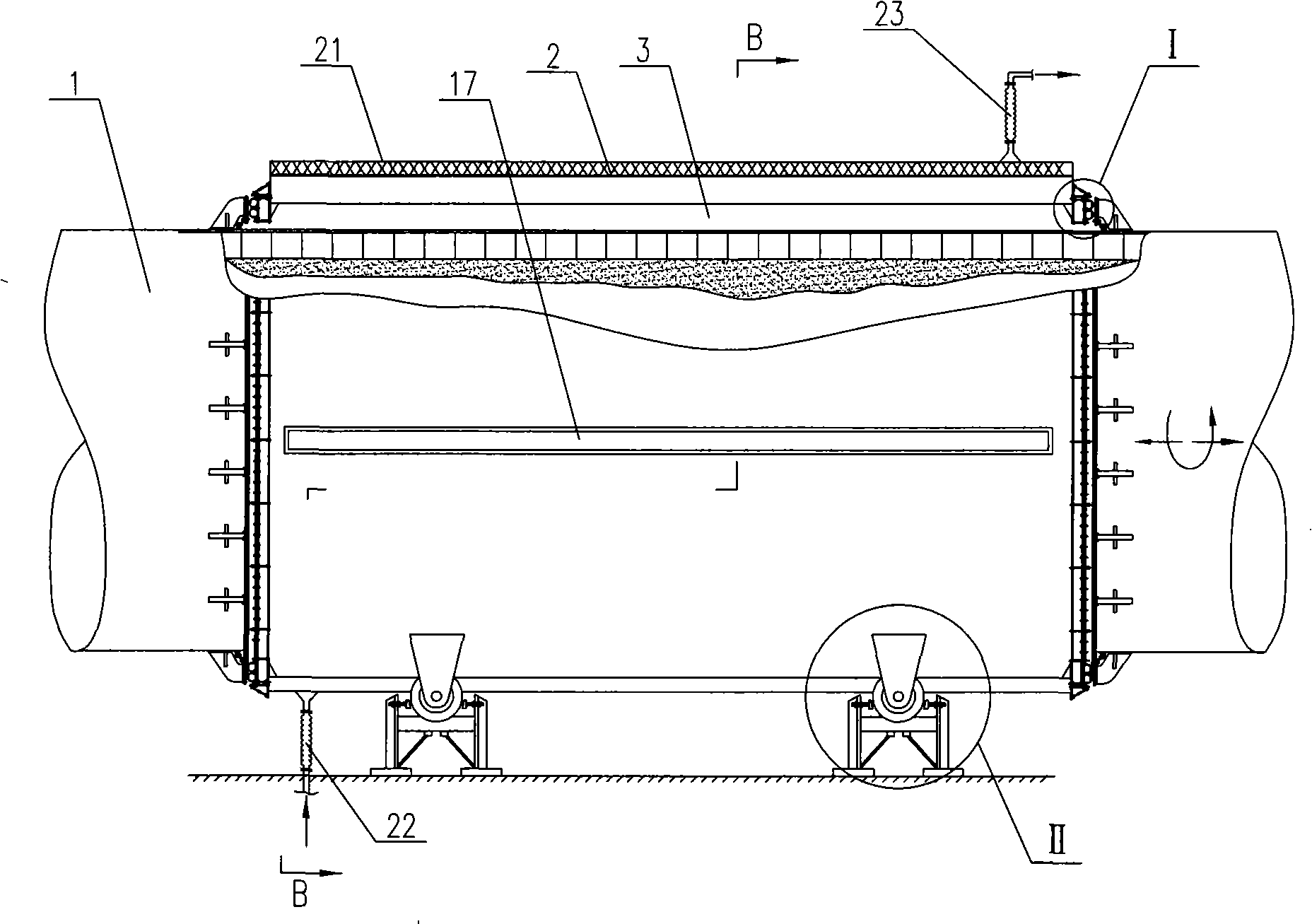

[0047] The cement rotary kiln shell heat dissipation recycling device includes the rotary kiln shell 1, the upper section of the rotary kiln shell 1 is provided with a heat exchange cover 2, and the heat exchange cover 2 is made of steel plates. Two semi-cylindrical bodies are connected by flanges Finally, the rotary kiln shell 1 is wrapped. The outer surface of the heat exchange cover 2 is provided with an insulating layer 21 to prevent heat loss. There is a sealing device between the two ends of the heat exchange cover 2 and the rotary kiln shell 1. The inner surface of the heat exchange cover 2 and the outer surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com