Treatment method and system for waste lye

A treatment method and a treatment system technology, which are applied in the field of waste lye treatment methods and treatment systems, can solve problems such as waste of resources, and achieve the effects of not being easy to foul and block, effective recycling, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

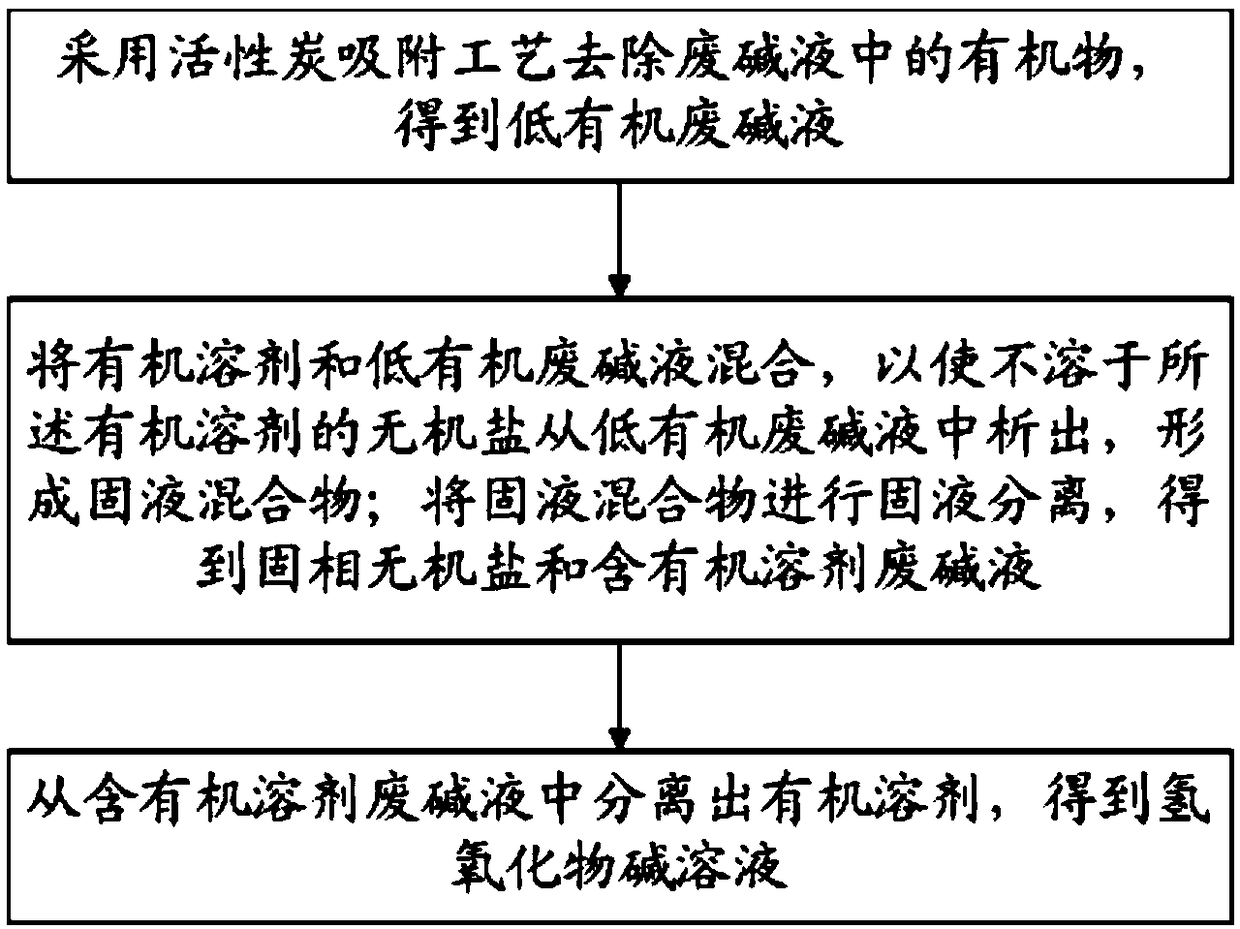

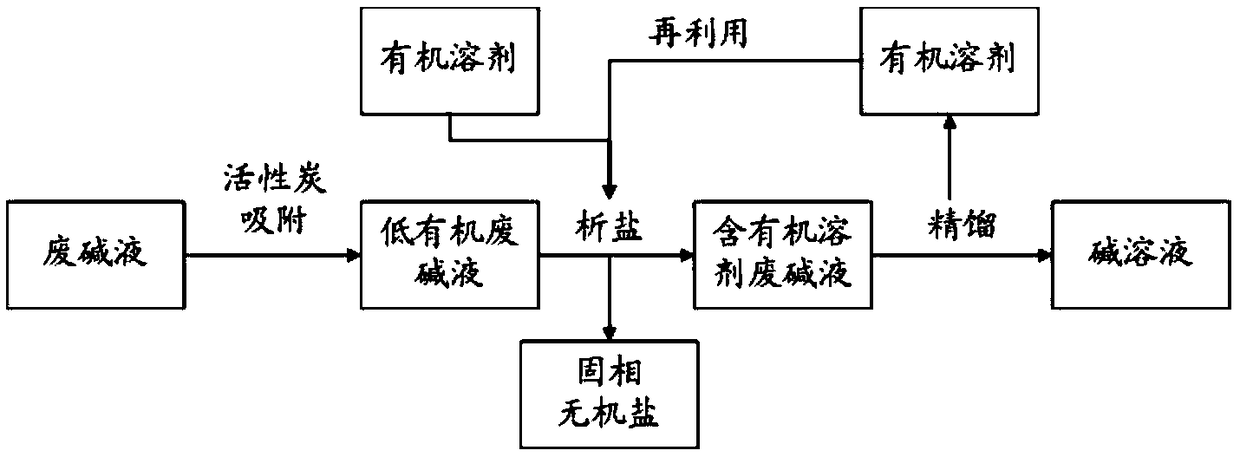

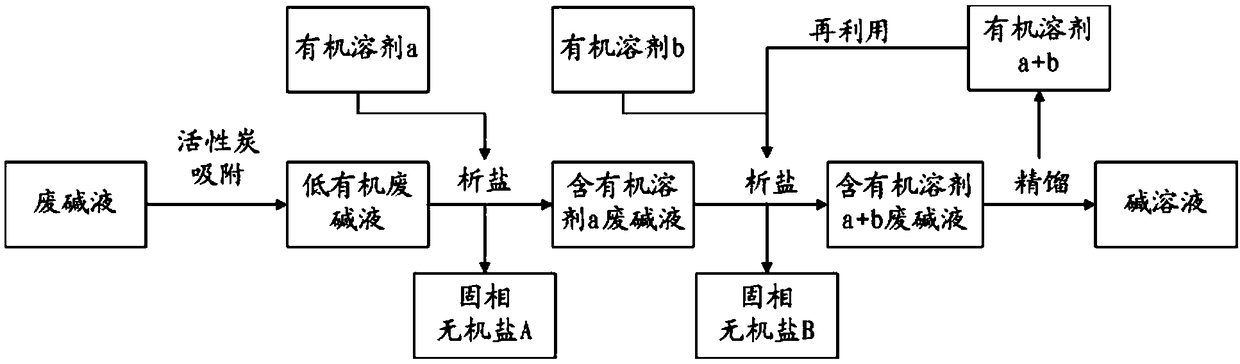

Method used

Image

Examples

Embodiment 1

[0056] In this embodiment, the waste caustic lye adopts the tertiary desulfurization liquid wastewater of ethylene alkali slag, and the total chemical oxygen demand (full name Chemical Oxygen Demand, COD for short) of the spent caustic liquor before treatment is 190000-200000mg / l, wherein organic COD is in 10000-20000mg / L, salt content 40%-50%, adopt described processing method provided by the present invention to process this waste lye, process and effect are as follows:

[0057] In the first step, the waste lye is introduced into a fixed bed of activated carbon, and the water is discharged after being adsorbed by activated carbon; after testing, the COD in the effluent is 170,000-180,000 mg / l, which is an inorganic salt COD, and the organic matter is almost completely removed;

[0058] The second step is to introduce the effluent from the first step and the alcoholic organic solvent into the salt separation unit under stirring, and treat for 1 to 24 hours to obtain a solid-li...

Embodiment 2

[0061] In this embodiment, waste caustic lye adopts ethylene alkali slag tertiary desulfurization liquid waste water, and the total COD of the waste caustic before treatment is 250,000-270,000 mg / l, wherein organic COD is 40,000-50,000 mg / L, and the salt content is 50%- 60%, adopt the described processing method provided by the invention to process this spent caustic soda, process and effect are as follows:

[0062] In the first step, the waste lye is introduced into a fixed bed of activated carbon, and the water is discharged after being adsorbed by activated carbon; after testing, the COD in the effluent is 200,000-220,000 mg / l, which is an inorganic salt COD, and the organic matter is almost completely removed;

[0063] The second step is to introduce the effluent from the first step and the alcoholic organic solvent into the salt separation unit under stirring, and treat for 1 to 24 hours to obtain a solid-liquid mixture; centrifuge the solid-liquid mixture at the solid-liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com