Gas purifying and cooling process and equipment of two-section furnace

A cooling process, gas technology, applied in the petroleum industry, manufacture of combustible gas, energy input, etc., can solve problems such as blockage of heat exchange tubes, high cost of gas equipment and production, affecting continuous production of gas, etc. The effect of reducing equipment manufacturing cost and maintenance cost and facilitating transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

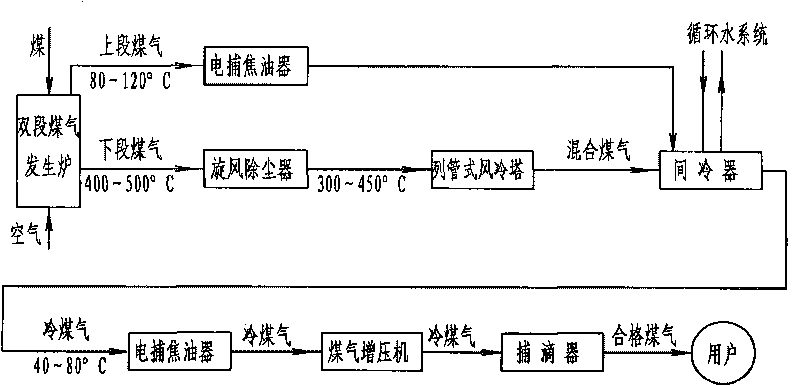

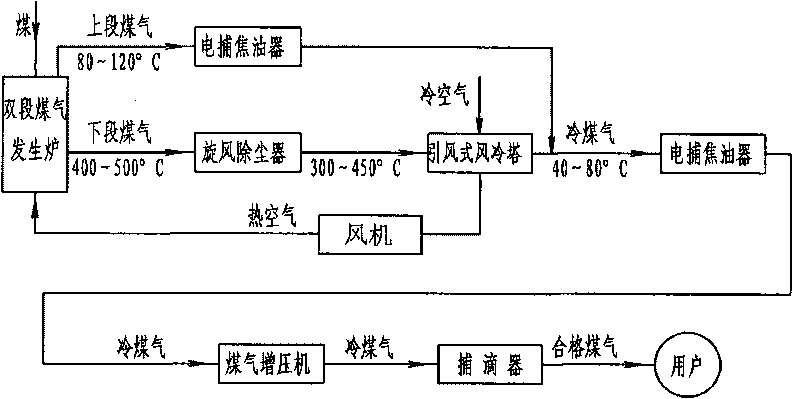

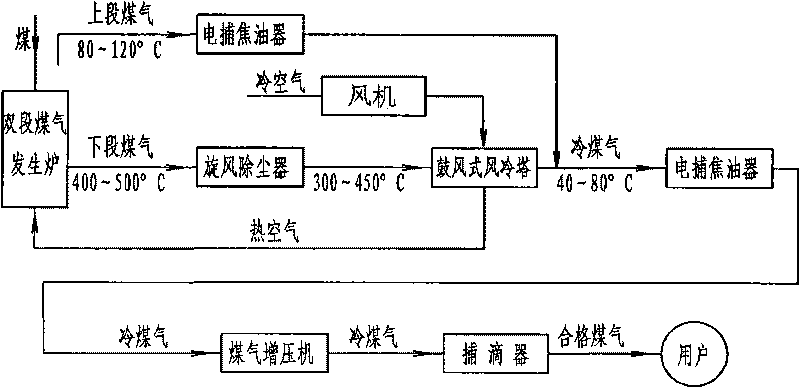

[0032] The concrete steps of the two-stage furnace gas purification and cooling process of the present invention are as follows:

[0033] a. The upper gas enters the electric tar catcher to remove heavy tar and dust to obtain purified crude gas;

[0034] b. The gas in the lower section is passed through the cyclone to remove the large particles of dust in the gas, and enters the air cooling tower for cooling, and the preheated air is sent to the two-stage gas furnace;

[0035] c. After the gas obtained from the upper section and the lower section is mixed, it enters the next-stage electric tar catcher to further remove tar impurities, pressurized by the gas booster, and then passes through the drop catcher to remove moisture and transport it to the user .

[0036] The preheated air in step b is sent into the two-stage gas furnace, which can be induced draft type: cold air first passes through the air cooling tower, and after heat exchange, it is introduced into the gas furnac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com