Feeding device of biogas pool

A technology of feeding device and biogas digester, applied in biochemical cleaning device, enzymology/microbiology device, waste fuel, etc., can solve the problems of organic matter crusting, biogas digester damage, unfavorable utilization of organic matter, etc. The effect of crusting and ensuring biogas yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

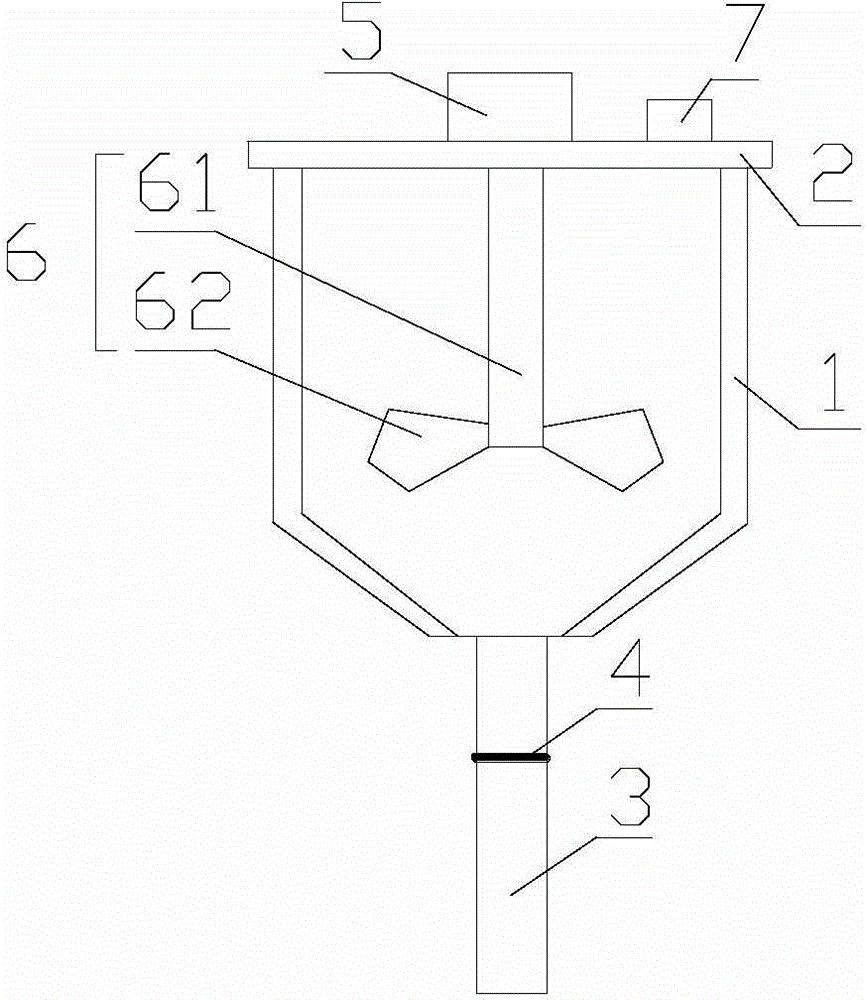

[0011] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of a feeding device for a biogas digester proposed by the present invention.

[0012] refer to figure 1 , the present invention proposes a feeding device for a biogas digester, comprising a feeding box 1, a discharge valve 4, a driving device 5, a stirring mechanism 6, a pressure sensor and a controller 7;

[0013] The top of the feeding box 1 is provided with a top cover 2, and its bottom has a discharge port. The discharge port is connected with a discharge pipe 3, and a discharge valve 4 is arranged in the discharge pipe 3; the driving device 5 is installed on the top cover 2 Above, the stirring mechanism 6 is located in the feeding box 1, the stirring mechanism 6 includes a stirring shaft 61 and two stirring parts 62, the stirring shaft 61 is connected with the output shaft of the driving device 5, and the two stirring parts 62 are respectively arranged on both sides of the stirring shaft 61 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com