A moving-bed reactor

A moving bed reactor and reactor technology, applied in chemical instruments and methods, chemical/physical processes, etc., can solve problems such as easy crusting of products, and achieve the effects of small footprint, reduced equipment, and simple structure

Active Publication Date: 2008-12-03

CHINA PETROLEUM & CHEM CORP +1

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

None of the above process equipment is suitable for the acid-base neutralization reaction and process in which the bulk material is neutralized with the liquid phase and the product is prone to crusting and fouling

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0013] A certain flue gas desulfurization water has a pH value of 3.4, using massive limestone with an average diameter of 5cm, the solid-liquid ratio in the neutralization equipment is 4:6 (weight ratio), the residence time of acidic water is 2min, and the pH value of the discharged water is It is 6.6, and it can run stably for a long time by adding alkaline substances regularly.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

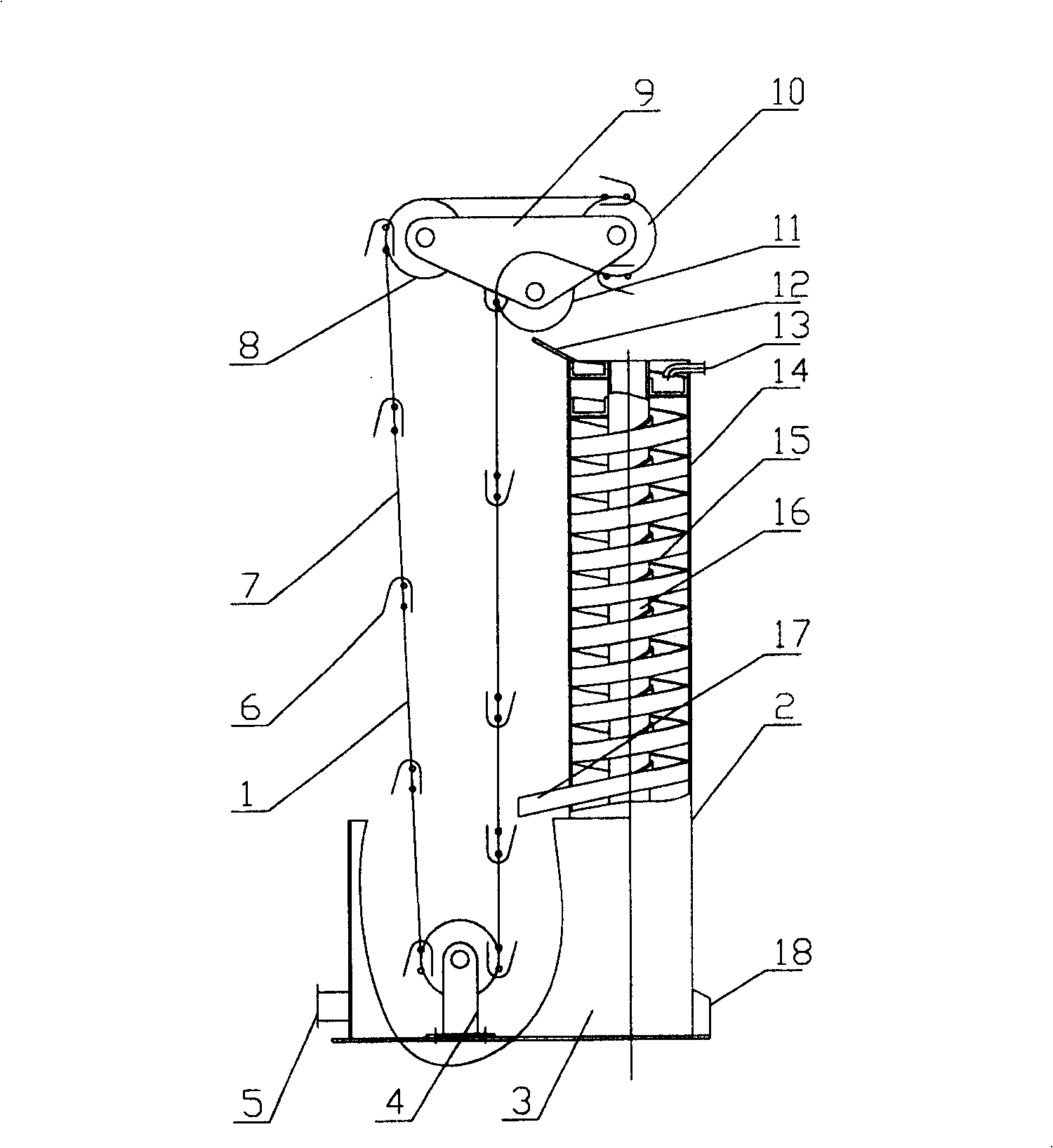

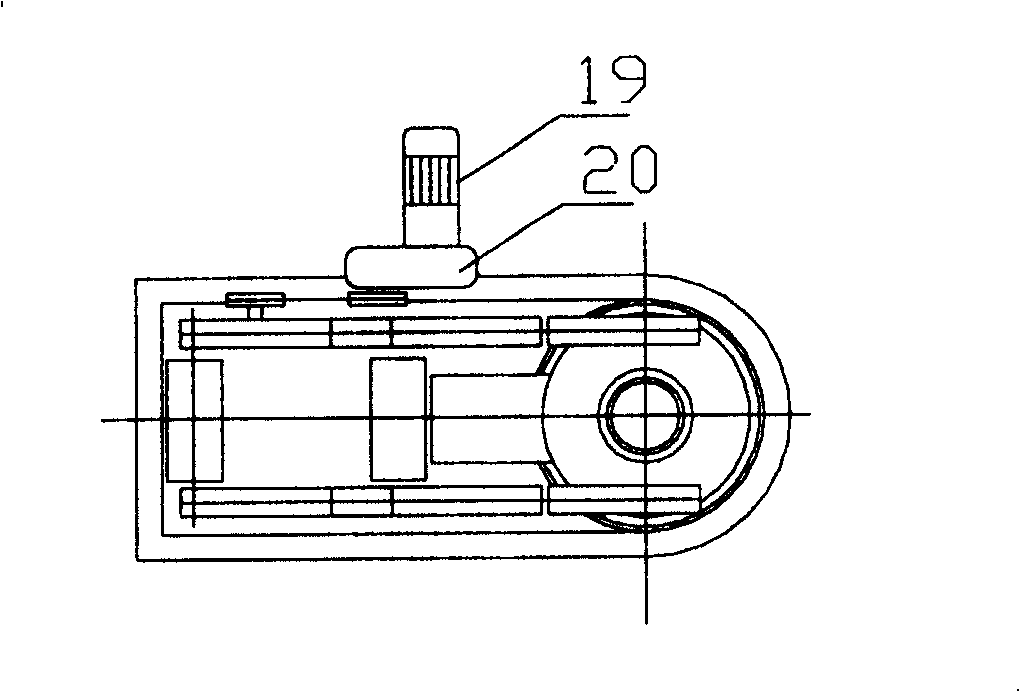

The invention relates to a move bed reactor, formed by screw reaction bed and lifter. Wherein, the screw reaction bed is formed by outer cylinder, inner cylinder, liquid inlet, material outlet, divert plate, screw reaction bed, and base; the lifter is formed by water tank, driven wheel water outlet, lifting hopper, chain, driving wheel, motor, speed reducer, and frame; the lifter and screw reaction bed share one chassis. The invention is used in solid-liquid neutralization; especially the solid is block material. The invention has simple structure without block.

Description

technical field [0001] The invention relates to a moving bed reactor, in particular to a moving bed used for neutralization reaction, belonging to the field of chemical equipment, in particular to a kind of equipment used for neutralization reaction in acidic water. Background technique [0002] Acid-base neutralization reaction is one of the common processes in chemical unit operation. The neutralization reaction is generally a liquid-liquid reaction or a liquid-solid acid-base reaction, and the reaction equipment used is: liquid-liquid reactions mostly use stirring equipment and static mixers, and when the solid phase is powder in the liquid-solid acid-base reaction, stirring equipment is generally used , cyclone or static mixer, when the solid phase is bulk material, neutralization tank, neutralization filter bed or neutralization filter are generally used. Some acid-base neutralization reaction products are prone to crusting and fouling, which is not conducive to the co...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B01J8/12

Inventor 刘忠生方向晨彭德强关明华齐慧敏戴文军

Owner CHINA PETROLEUM & CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com