Film gluing mechanism with page capable of being quickly replaced

A layout and film technology, applied in the field of film gluing mechanism that can quickly change the layout, can solve the problems of low manual gluing efficiency, glue deposition and solidification, etc., and achieve the effect of quick installation and no skinning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following description is merely exemplary in nature and not intended to limit the disclosure, application or use. The specific implementation of the film gluing mechanism that can quickly change the layout of the present invention will be further described below in conjunction with the accompanying drawings.

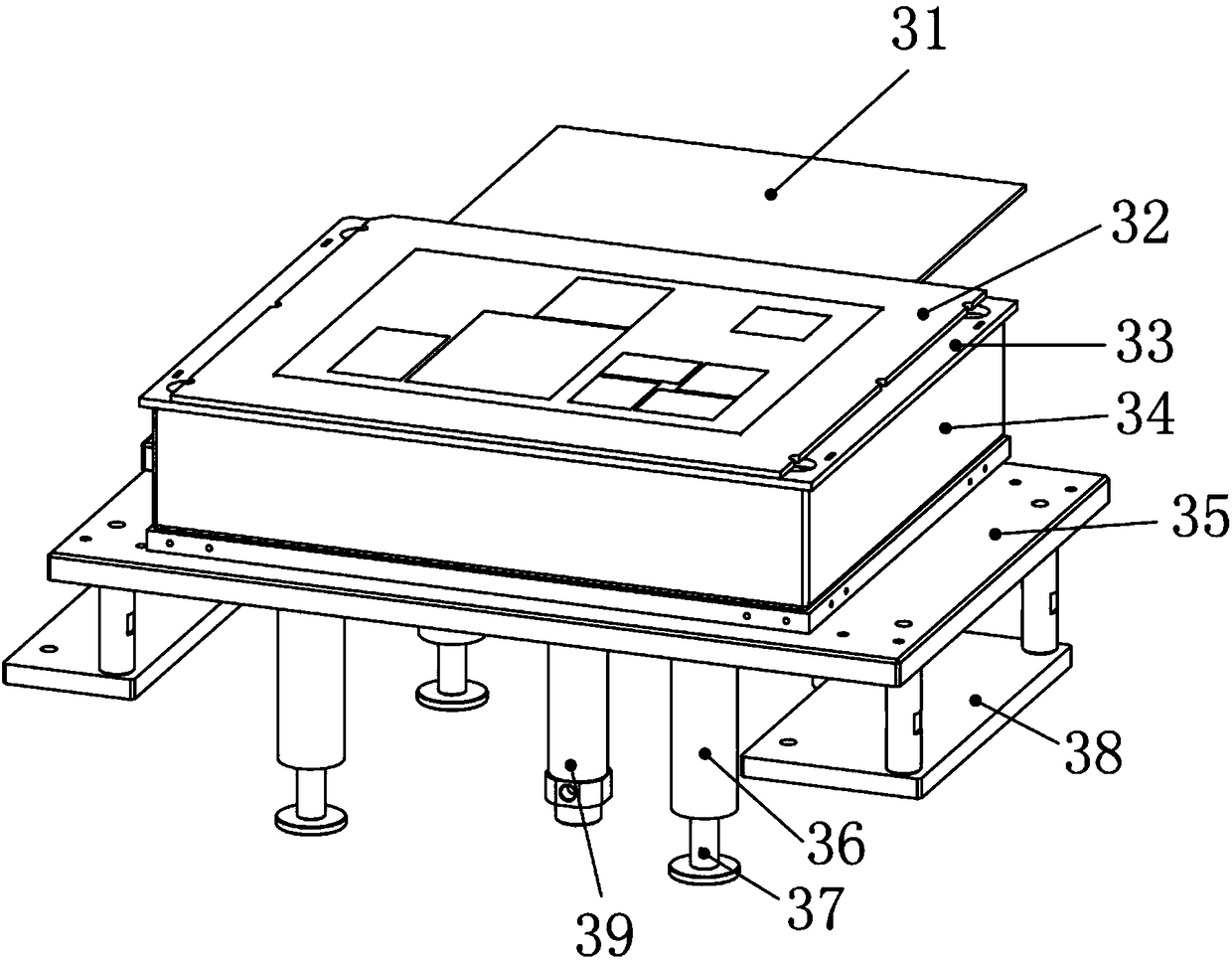

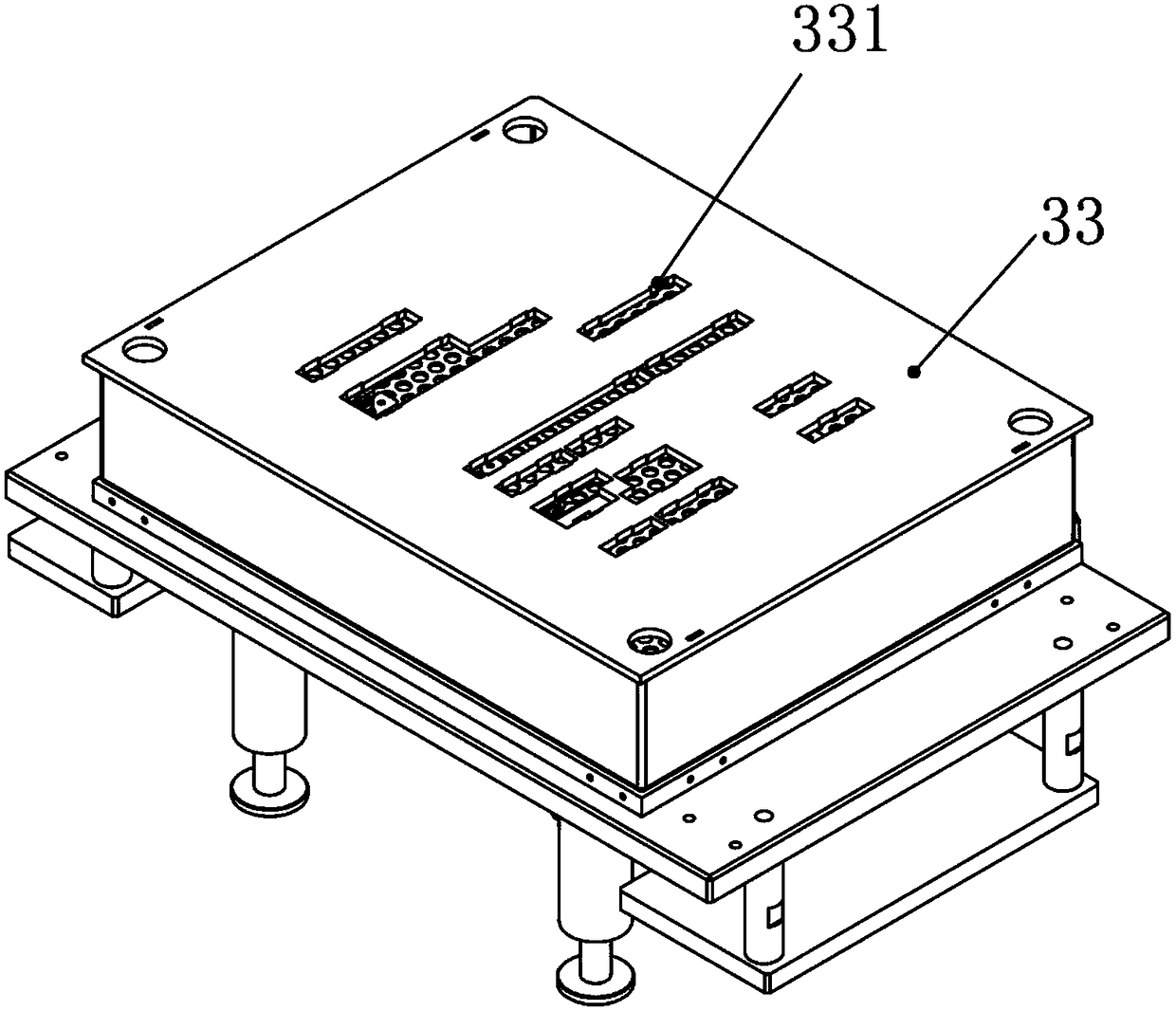

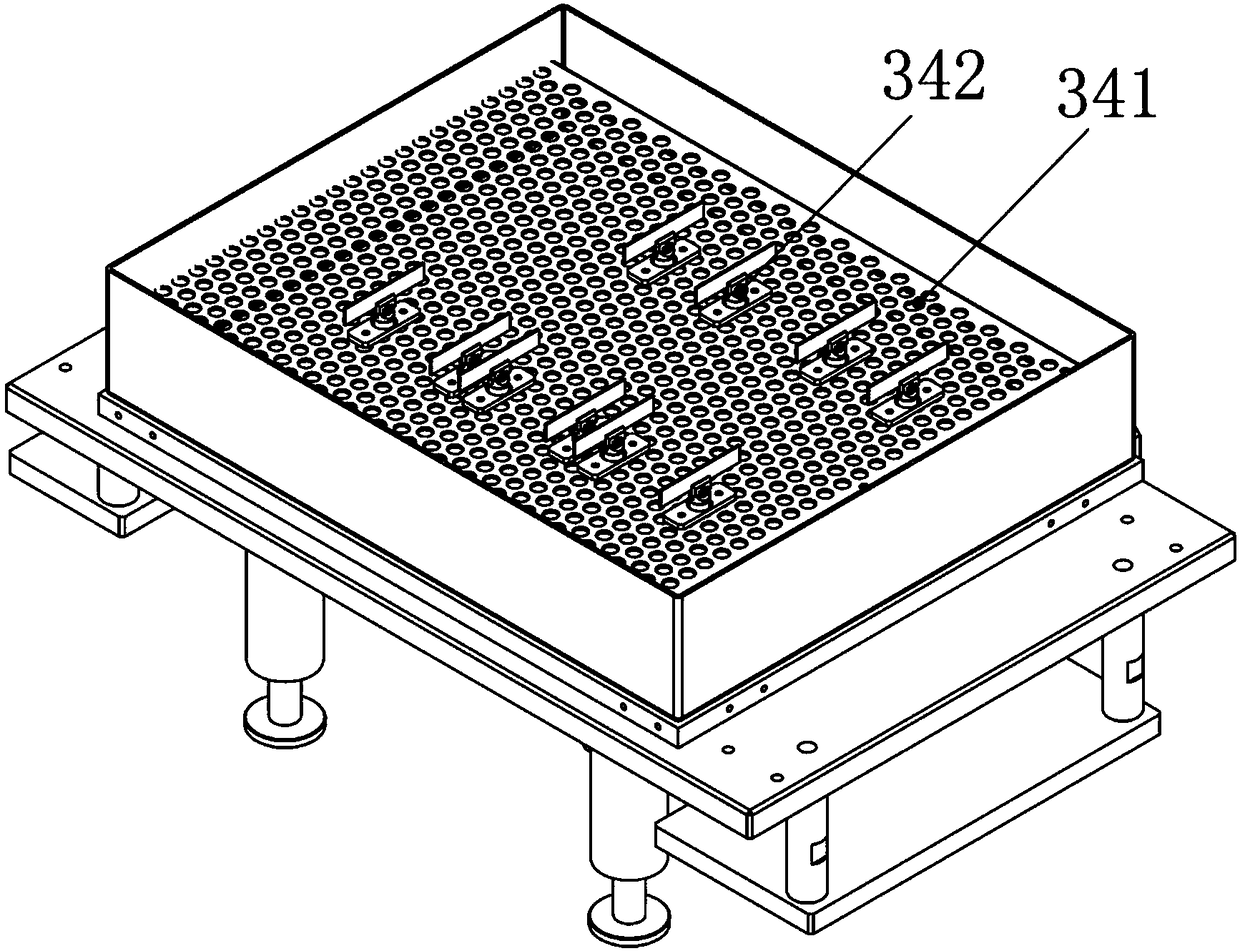

[0033] Such as figure 1 , image 3 Shown is a schematic structural view of a preferred embodiment of the film gluing mechanism capable of quickly changing the layout according to the present invention. A film gluing mechanism that can quickly replace the layout of the present invention includes a glue tank 34 and a glue tank cover plate 33 located on the upper part of the glue tank. The inside of the glue tank 34 is provided with a plurality of glue knives 342, the glue knives 342 is located on the gluing knife mounting plate 341; the top of the glue groove cover plate 33 is provided with an alignment plate 32 and a new stamp page template 31.

[0034] In t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com