Concentrated acid hydrolysis system used for organochlorosilane concentrated acid hydrolysis

A hydrolysis technology of organochlorosilane and concentrated acid, which is applied in the direction of silicon organic compounds, can solve the problems of low reactor efficiency, increased reaction residence time, and easy emulsification of liquid, so as to achieve reasonable process flow, reduce mist entrainment, and promote hydrolysis The effect of the reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

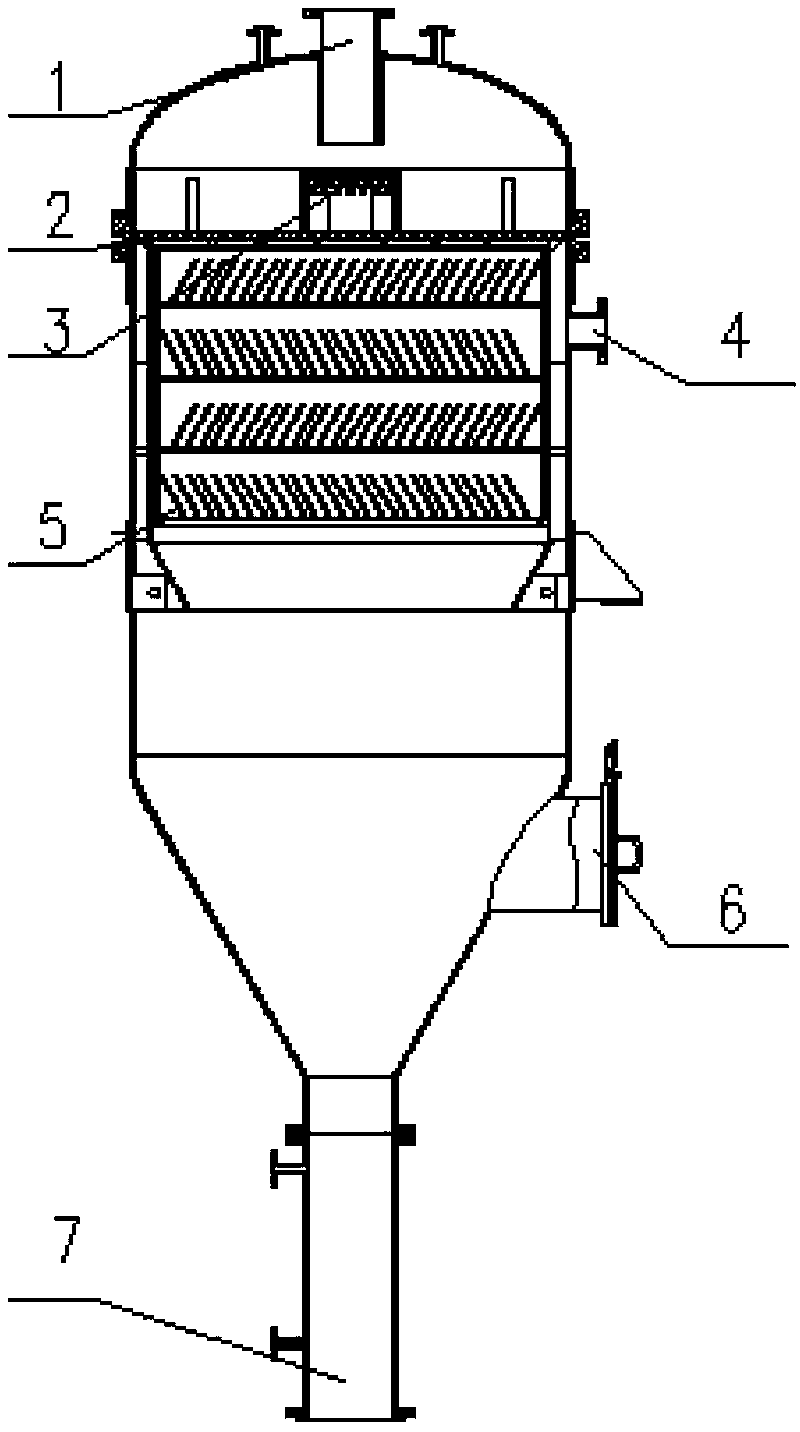

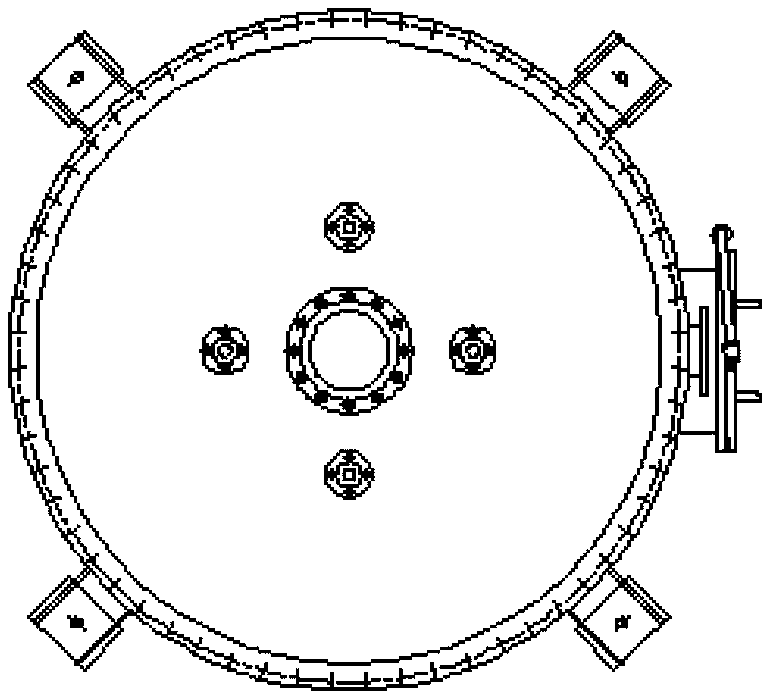

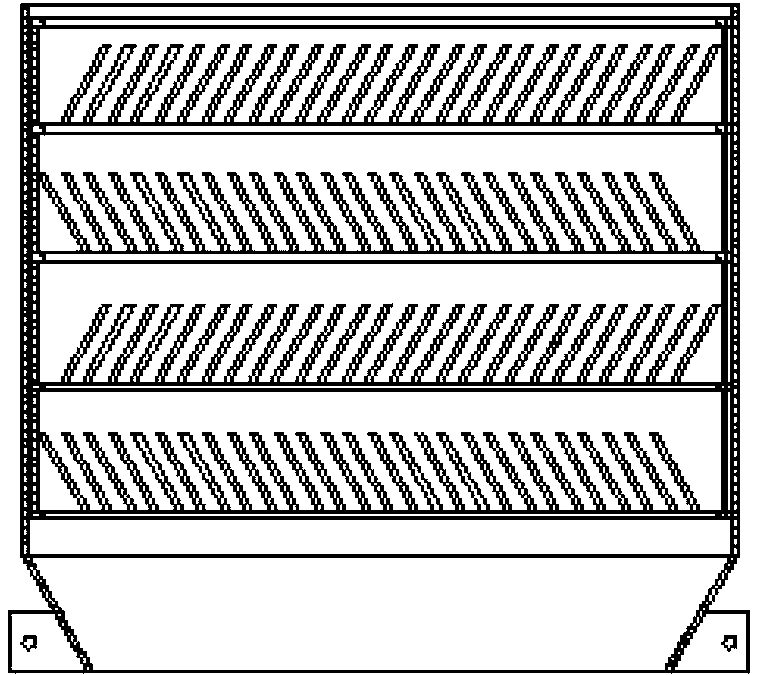

[0026] A kind of dispersed liquid membrane type desorption tower that is used for organochlorosilane concentrated acid hydrolysis, such as Figure 1-3 As shown, it includes the shell, which has a support, an upper head and a lower cone, a flange, an outer cylinder, and is connected and sealed by fasteners; the shell also includes an inner cylinder; the top of the desorption tower There is a liquid inlet 1, a liquid outlet 7 at the bottom, and an air outlet 4 on the side of the outer cylinder; a liquid distribution plate 2 is fixedly installed between the upper head and the outer cylinder, and the top of the liquid distribution plate 2 is Anti-splash screen, below the liquid distribution plate 2 is a neatly arranged film-forming plate 5, and the film-forming plate is horizontally supported, with a total of 3 to 10 layers. The angle between the forming template 5 and the horizontal plane is 15-75 degrees. In between, the film-forming plates are arranged in a staggered direction;...

Embodiment 2

[0029] A concentrated acid hydrolysis system for the concentrated acid hydrolysis of organochlorosilanes, such as Figure 4 As shown, it includes the dispersed liquid film desorption tower 9 of Example 1, and also includes a static mixer 8, a rough separator 10, and a falling film evaporator 14. The static mixer 8 is respectively provided with a dimethylformamide inlet 13 and a concentrated acid inlet 14, and its outlet is connected to a dispersed liquid membrane type analysis tower 9; the liquid outlet of the dispersed liquid membrane type analysis tower 9 is connected to a rough separator 10, and after rough separation The hydrogen chloride separated by the device enters the subsequent falling film evaporator 11, and the hydrogen chloride gas obtained after evaporation is discharged through the HCl outlet 12, and the hydrochloric acid solution obtained by concentrating at the bottom is connected to the concentrated acid inlet 14 of the static mixer 8 through pipelines to be r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com