Continuous solution polymerization process for pre-polymerizing spandex

A polymerization method and pre-polymerization technology, applied in the direction of one-component synthetic polymer rayon, fiber chemical characteristics, one-component polyurethane rayon, etc., can solve the difficulty of cooling, can not achieve continuous polymerization, and prepolymer viscosity is high question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

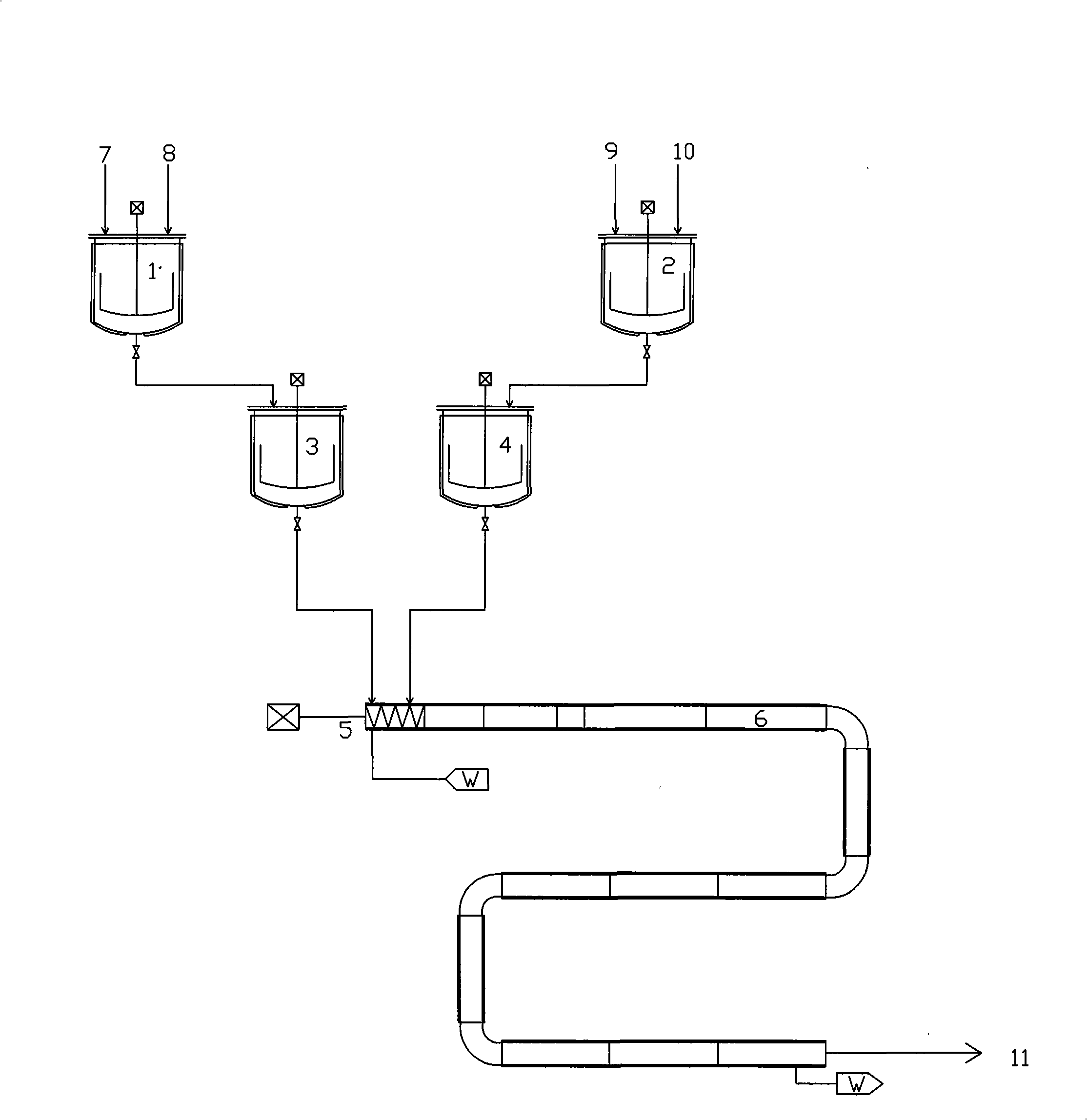

[0033] Add 150kg of N,N-dimethylacetamide (DMAC) or N,N-dimethylformamide 9 to the diisocyanate dissolving kettle 1, lower the temperature of the system to 5 degrees, and slowly add 150kg of molten state under stirring 4,4'-diphenylmethane diisocyanate (MDI) 7, after completely dissolving, stir evenly, put into the temporary storage tank 3 of diisocyanate solution for subsequent use; Add 674.3 kg of molten polytetramethylene ether glycol (PTMG) or poly(tetramethylene-3-methyl-tetramethylene ether) glycol 8 (molecular weight is 1800), the system temperature is reduced to 5 degree, dissolved into 674.3kg of N, N-dimethylacetamide (DMAC) or N, N-dimethylformamide 9, put into polyether glycol solution temporary storage tank 4 for subsequent use.

[0034] With the flow rate of 50kg / h, 4,4'-diphenylmethane diisocyanate (MDI) solution is pumped into the high-speed dynamic mixer 5 with a metering pump, and the poly(IV) Methylene ether glycol (PTMG) solution was mixed. The mixed reac...

Embodiment 2

[0035] Embodiment 2: Add 122.2kg of N,N-dimethylacetamide (DMAC) or N,N-dimethylformamide 9 in the diisocyanate dissolving kettle 1, reduce the system temperature to 10 degrees, slowly stir Slowly add 4,4'-diphenylmethane diisocyanate (MDI) 7 of the solid state of 100kg pulverization, after dissolving completely, stir well, put into diisocyanate solution temporary storage tank 3 for subsequent use; Add 470.1kg of molten polytetramethylene ether glycol (PTMG) or poly(tetramethylene-3-methyl-tetramethylene ether) glycol 8 (molecular weight is 2000) in the ether glycol dissolving kettle 2 , the system temperature is reduced to 5 degrees, dissolved in 574.6kg of N,N-dimethylacetamide (DMAC) or N,N-dimethylformamide 9, and put into the polyether glycol solution temporary storage tank 4 in spare.

[0036]With the flow rate of 45kg / h, 4,4'-diphenylmethane diisocyanate (MDI) solution is pumped into the high-speed dynamic mixer 5 with a metering pump, and the poly(IV) Methylene ether...

Embodiment 3

[0037] Embodiment 3: Add 150kg of N,N-dimethylacetamide (DMAC) or N,N-dimethylformamide 9 in the diisocyanate dissolving kettle 1, reduce the system temperature to 15 degrees, and slowly Add 4,4'-diphenylmethane diisocyanate (MDI) 7 of the solid state of 100kg pulverization, after dissolving completely, stir well, put into diisocyanate solution temporary storage tank 3 for subsequent use; Use the same method, in polyether Polytetramethylene ether glycol (PTMG) or poly(tetramethylene-3-methyl-tetramethylene ether) glycol 8 (molecular weight is 1800) of the polytetramethylene ether glycol (PTMG) of the solid state that adds 411kg pulverizing in the glycol dissolving kettle 2 ), the system temperature is reduced to 5 degrees, dissolved into 616.5kg of N,N-dimethylacetamide (DMAC) or N,N-dimethylformamide 9, and put into a temporary storage tank for polyether glycol solution 4 spare.

[0038] With the flow rate of 50kg / h, 4,4'-diphenylmethane diisocyanate (MDI) solution is pumped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com