Movable-cover-free cyclic feeding and discharging type methane-generating pit

A biogas digester, feeding and discharging technology, applied in the field of biogas digesters, can solve the problems of not producing biogas, affecting biogas, less biogas, etc., and achieving the effects of easy operation, not easy to leak, and easy to operate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

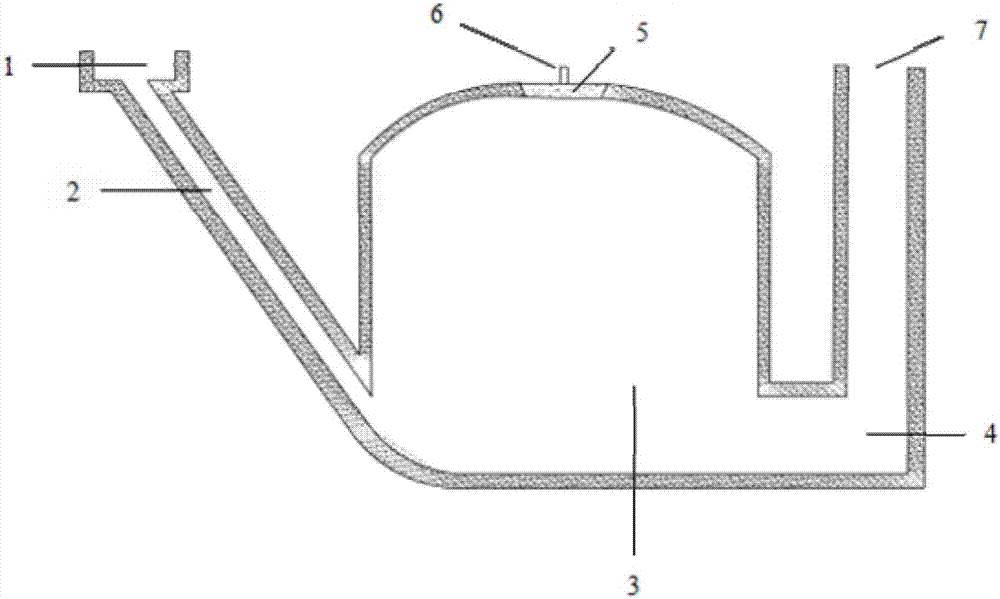

[0023] The schematic diagram of the structure of a kind of biogas digester with a movable cover that circulates in and out of materials described in this embodiment is shown in figure 1 shown.

[0024] The biogas digester described in this embodiment is composed of a feed port 1, a feed pipe 2, a biogas digester body 3, a water pressure room 4, a prefabricated capping cover 5, an air guide pipe 6, and a discharge chamber. Composed of mouth 7; feed pipe 2 is installed above the bottom of biogas tank body 3, and the other end of feed pipe 2 leads upwards to communicate with feed port 1; there is a channel at the bottom of biogas tank body 3 and the bottom of water pressure room 4 Connected, the upper end of the water pressure room 4 has a discharge port 7; the prefabricated capping cover 5 is installed on the upper part of the biogas digester body 3, and the prefabricated capping cover 5 and the biogas digester body 3 are sealed and connected; the air duct 6 is installed on the ...

Embodiment 2

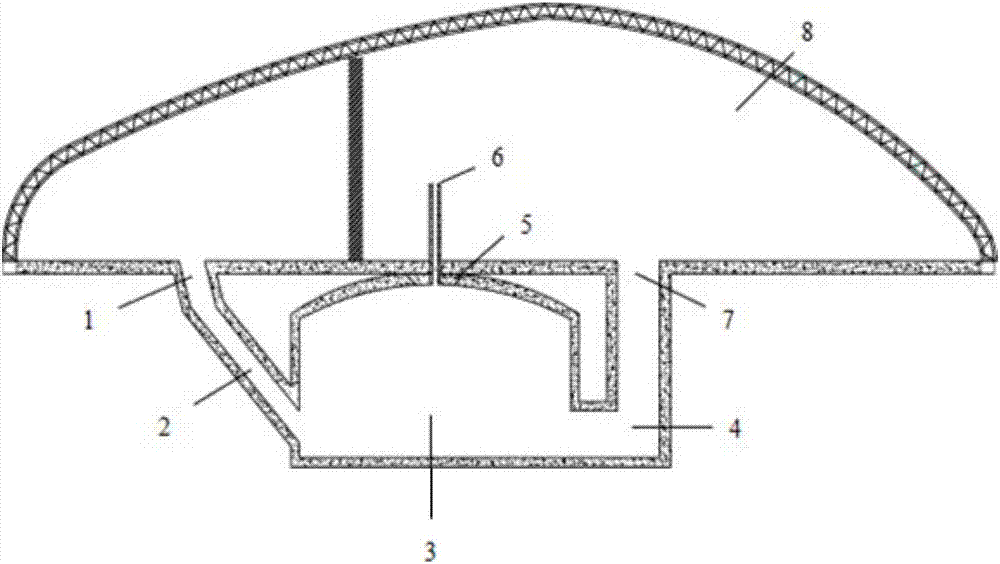

[0034] The schematic diagram of the structure of a kind of biogas digester with a movable cover that circulates in and out of materials described in this embodiment is shown in figure 2 shown.

[0035] The structure of the biogas digester without movable cover circulation in and out of material described in this embodiment is basically the same as that of the biogas digester in Example 1, the difference is that the activity-free The cover cycle feeding and discharging type biogas digester is installed under the ground in the solar greenhouse 8, and the solar greenhouse 8 is used to increase the temperature of the biogas digester so that it can also produce biogas in winter, which solves the problem of no or little gas production in the northern winter of the biogas digester. At the same time, the biogas digester built in the solar greenhouse 8 can be well combined with the cultivation of vegetables in the solar greenhouse. The biogas slurry and residue produced after anaerobi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com