High-efficiency zinc alloy sacrificial anode for high-temperature crude oil deposition water environment

A sacrificial anode, water environment technology, applied in the field of high-efficiency zinc alloy sacrificial anode, can solve problems such as failure, and achieve the effects of large driving voltage, high efficiency and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

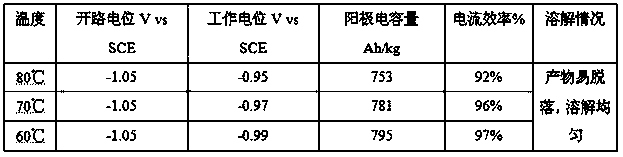

[0017] Embodiment 1: the formula of a kind of zinc alloy sacrificial anode that the present invention relates to is (weight percent) A1: 0.10%; Mg: 0.05%; Sn: 0.005%; Impurity content: Pb≤0.006%; Cd≤0.001%; Cu ≤0.001%; Fe≤0.002%; the balance is Zn; according to the GB / T 17848-1999 standard measurement method, its electrochemical performance is shown in Table 1.

[0018] Table 1 Electrochemical performance of high temperature zinc alloy sacrificial anode (in sea oil sewage)

[0019]

Embodiment 2

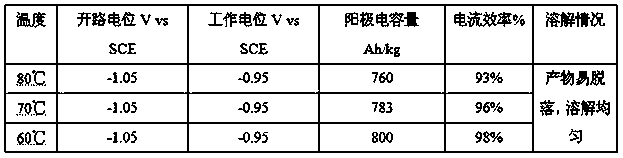

[0020] Embodiment 2: The formulation of another zinc alloy sacrificial anode involved in the present invention is (weight percent) A1: 0.25%; Mg: 0.15%; Sn: 0.009%; impurity content: Pb≤0.006%; Cd≤0.001%; Cu≤0.001%; Fe≤0.002%; the balance is Zn; according to GB / T 17848-1999 standard measurement method, its electrochemical performance is shown in Table 2.

[0021] Table 2 Electrochemical performance of high temperature zinc alloy sacrificial anode (in sea oil sewage)

[0022]

[0023] In addition, the composition content of the zinc alloy sacrificial anode involved in the present invention is between the above-mentioned examples 1 and 2. Using the same process and measurement method as the above-mentioned examples, its electrochemical performance is between Table 1 Between and Table 2 (not repeated).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com