Aluminum alloy anode suitable for high-resistivity environment and preparation method for aluminum alloy anode

A high-resistivity, aluminum alloy technology, applied in the field of corrosion and protection, can solve the problems of limited application, uneven corrosion pattern of working potential, etc., to achieve the effect of convenient control, mild conditions, and improved working potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] A method for preparing an aluminum alloy anode suitable for a high-resistivity environment of the present invention comprises the following steps: 1) taking an aluminum ingot as a raw material for the aluminum element, heating the crucible to 700-800° C., and melting the aluminum ingot; 2) The raw materials of zinc, indium, tin, silicon and titanium were weighed respectively, added to the molten aluminum liquid obtained in step 1), stirred evenly with a graphite rod, slag removed, cast into a mold, cooled, and taken out to obtain an anode.

[0028] Preferably, 10% or 20% aluminum-silicon alloy is used as the raw material for the silicon element, and aluminum-titanium alloy or titanium boride is used as the raw material for the titanium element.

Embodiment 1

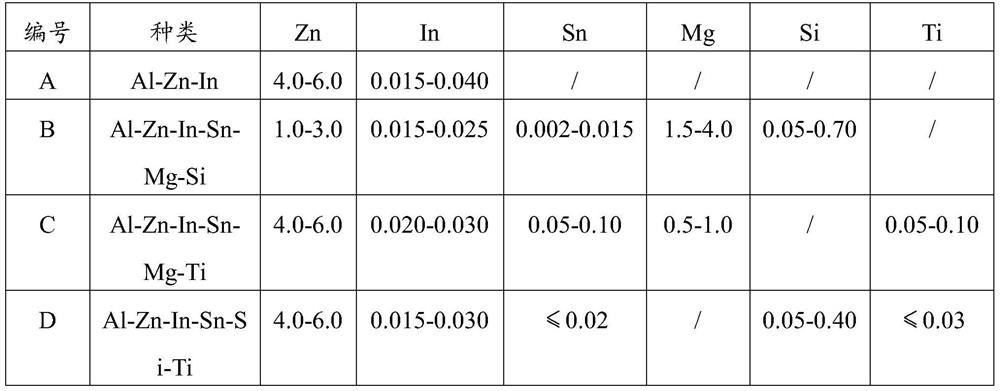

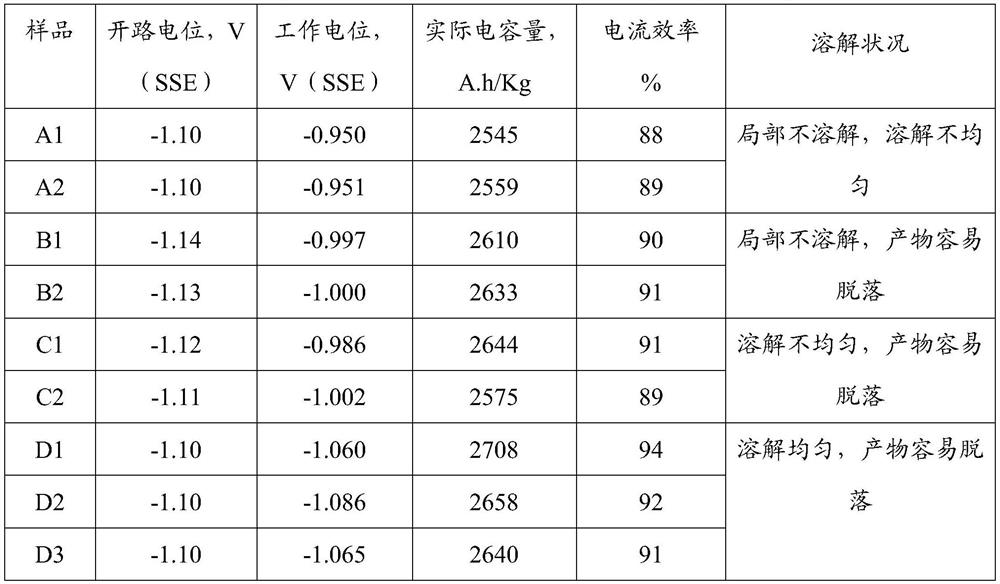

[0030] The commercially available 99.85Al ingot is used as the raw material, and the crucible is heated to 700-800°C to melt the aluminum ingot. Add the raw materials of Zn, In, Sn, Si and Ti elements, stir evenly, remove slag, cast into the required mold, take out the anode after cooling. Concrete embodiment formula ratio is as follows:

[0031] In weight percentage: Zn: 4.0%; In: 0.02%; Si: 0.2%; Sn: 0.01%; Ti: 0.03%; impurity content: Fe: 0.07%; Cu: 0.001%; the balance is Al. The sample number is D1.

[0032] Among them, the anode is manufactured by casting method, the silicon element is made of 10% or 20% aluminum-silicon alloy as raw material, the titanium element is made of aluminum-titanium alloy or titanium boride, and the three elements of zinc, indium and tin are respectively made of corresponding metal elements For the raw material.

Embodiment 2

[0034] The sample number is D2, and the formula of the aluminum alloy anode is calculated as:

[0035] Zn: 5.5%; In: 0.03%; Si: 0.40%; Sn: 0.015%; Ti: 0.02%; impurity content: Fe: 0.07%; Cu: 0.001%;

[0036] The anode is manufactured by melting and casting, and the casting method is the same as in Example 1. The silicon element is made of 10% or 20% aluminum-silicon alloy as the raw material, the titanium element is made of aluminum-titanium alloy or titanium boride, and the three elements of zinc, indium and tin are respectively The corresponding metal element is used as raw material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com