Starting method of magnesium electrolytic cell

A magnesium electrolytic cell and electrolytic cell technology, applied in the field of start-up of a multipolar magnesium electrolytic cell, to achieve the effects of not easy crusting, prolonging service life, and reducing electrode stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

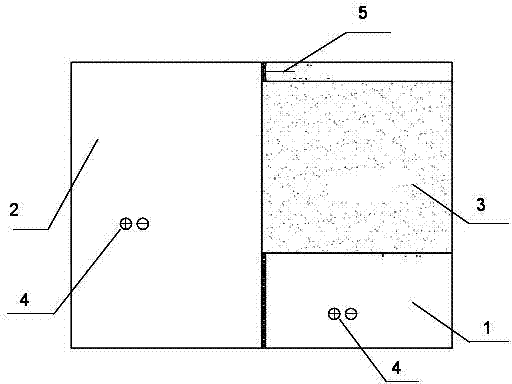

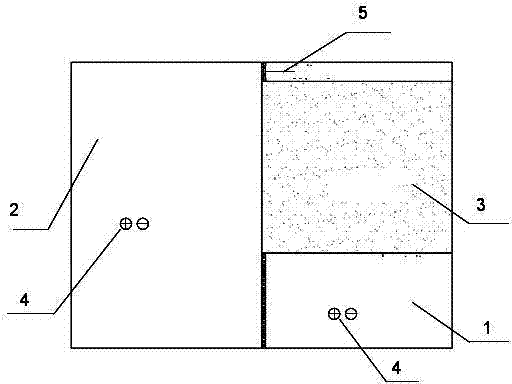

[0011] Below in conjunction with accompanying drawing, content of the present invention is described in further detail

[0012] A method for starting a magnesium electrolytic cell. Firstly, a set of AC electrodes 4 are respectively arranged at the bottom of the electrolytic chamber 1 of the multipolar magnesium electrolytic cell and the middle of the magnesium collecting chamber 2. The two groups of electrodes are controlled separately. When the electrolytic cell is started, a pre-configured If the electrolyte does not pass through the AC electrode 4 at the bottom of the electrolysis chamber 1, it will start to send AC current to the electrode; continue to add the electrolyte until it stops at 50 mm to 60 mm below the bottom of the cathode 3, heat to 680°C to 700°C and keep the temperature constant for more than 4 hours; then add the electrolyte To the standard liquid level 5, when the electrolyte is submerged in the AC electrode in the middle of the magnesium collection chambe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com