Defoaming agent for paint and ink and preparation method thereof

A coating ink, defoamer technology, applied in the direction of ink, application, coating, etc., can solve the problems of poor high temperature resistance and stability, poor silicone dispersion, poor compatibility of coatings, etc., to achieve high temperature resistance and stability. Strong, Compatible, Fast Foam Suppression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

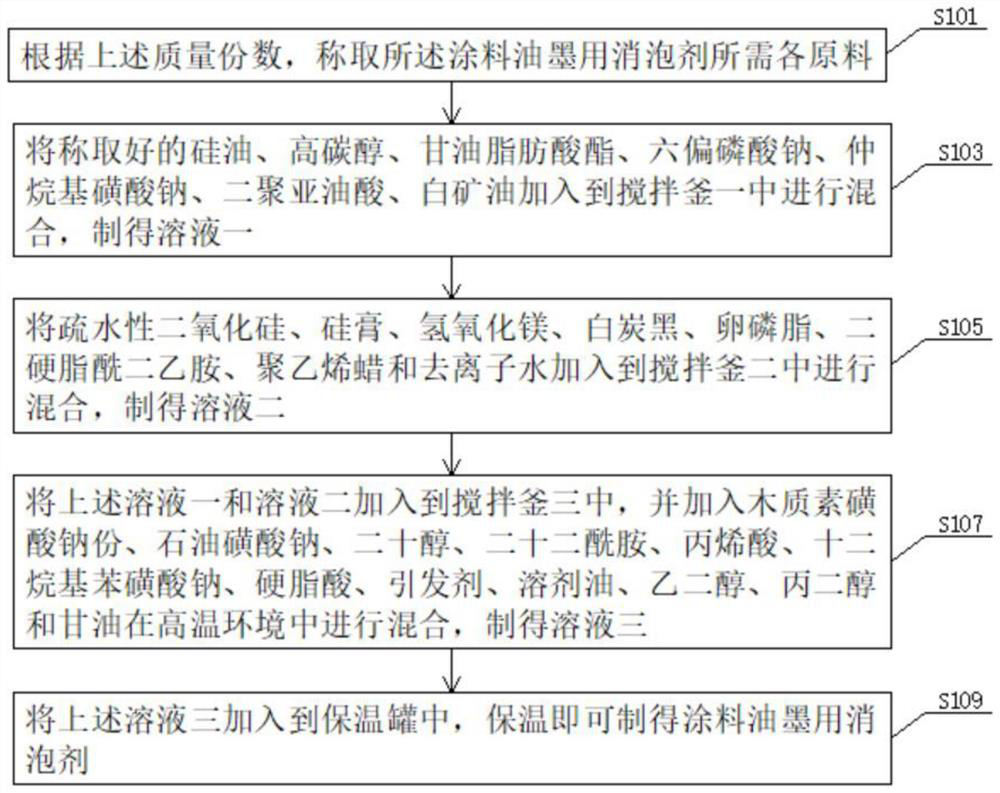

Method used

Image

Examples

Embodiment 1

[0054] A kind of defoamer for paint ink, this defoamer for paint ink is made of the following raw materials in parts by mass:

[0055] Silicone oil 42g, hydrophobic silicon dioxide 14g, silicone paste 14g, higher alcohol 10g, glycerin fatty acid ester 1g, sodium hexametaphosphate 3g, sodium secondary alkyl sulfonate 1g, magnesium hydroxide 4g, dimer linoleic acid 5g , white carbon black 5g, white mineral oil 4g, surfactant 8g, polyethylene wax 20g, lecithin 10g, thickener 7g, co-emulsifier 4g, distearyl diethylamine 16g and deionized water 90g.

[0056] Wherein, the surfactant includes the following raw material components: 4 g of sodium lignosulfonate, 2 g of sodium petroleum sulfonate, 1 g of eicosanol and 1 g of behenic acid amide.

[0057] The thickener includes the following raw material components: 1g of acrylic acid, 1g of sodium dodecylbenzenesulfonate, 1g of stearic acid, 1g of initiator and 3g of mineral spirits.

[0058] The co-emulsifier comprises the following ra...

Embodiment 2

[0066] A kind of defoamer for paint ink, this defoamer for paint ink is made of the following raw materials in parts by mass:

[0067] Silicone oil 45g, hydrophobic silicon dioxide 17g, silicone paste 16g, higher alcohol 15g, glycerin fatty acid ester 2g, sodium hexametaphosphate 4g, sodium secondary alkyl sulfonate 1.5g, magnesium hydroxide 7g, dimer linoleic acid 8g, white carbon black 6g, white mineral oil 6g, surfactant 11g, polyethylene wax 25g, lecithin 11g, thickener 12.5g, co-emulsifier 9g, distearamide 18g and deionized water 100g .

[0068] Wherein, the surfactant includes the following raw material components: 5 g of sodium lignosulfonate, 2.5 g of sodium petroleum sulfonate, 1.5 g of eicosanol and 2 g of behenic acid amide.

[0069] The thickener comprises the following raw material components: 2g of acrylic acid, 1.5g of sodium dodecylbenzenesulfonate, 2.5g of stearic acid, 1.5g of initiator and 5g of mineral spirits.

[0070] The co-emulsifier comprises the fol...

Embodiment 3

[0078] A kind of defoamer for paint ink, this defoamer for paint ink is made of the following raw materials in parts by mass:

[0079] Silicone oil 48g, hydrophobic silicon dioxide 20g, silicone paste 18g, higher alcohol 20g, glycerin fatty acid ester 3g, sodium hexametaphosphate 5g, sodium secondary alkyl sulfonate 2g, magnesium hydroxide 10g, dimer linoleic acid 11g , white carbon black 7g, white mineral oil 8g, surfactant 14g, polyethylene wax 30g, lecithin 12g, thickener 18g, co-emulsifier 14g, distearamide 20g and deionized water 110g.

[0080] Wherein, the surfactant includes the following raw material components: 6 g of sodium lignosulfonate, 3 g of sodium petroleum sulfonate, 2 g of eicosanol and 3 g of behenic acid amide.

[0081] The thickener includes the following raw material components: 3g of acrylic acid, 3g of sodium dodecylbenzenesulfonate, 4g of stearic acid, 2g of initiator and 7g of mineral spirits.

[0082] The co-emulsifier comprises the following raw ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com