Blue fluorescent powder for white-light LED and preparation method thereof

A technology of blue phosphor and white light, applied in the field of blue phosphor for white light LED and its preparation, can solve the problems of low purity and luminous performance of phosphor, complicated spray pyrolysis process, and difficulty in large-scale production, etc. Good chemical stability and thermal stability, shortened chemical reaction time, the effect of short time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

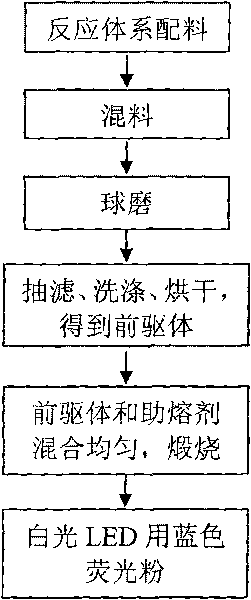

Method used

Image

Examples

Embodiment 1

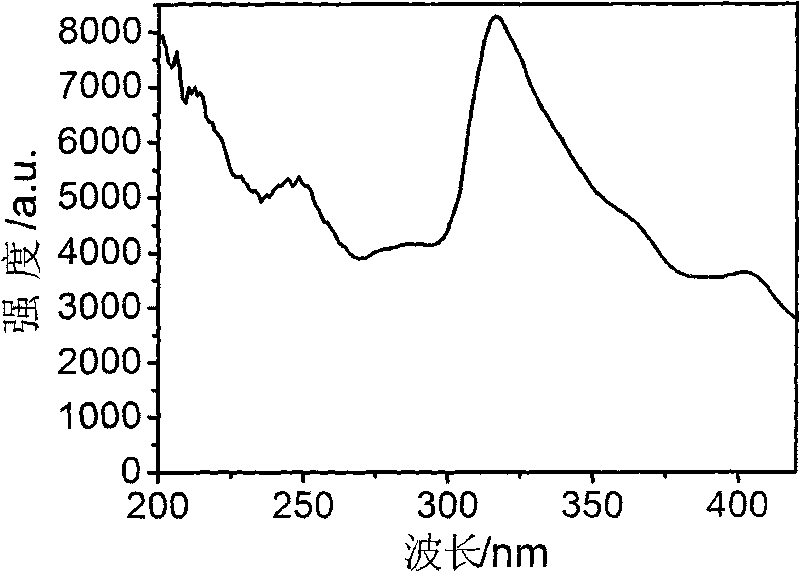

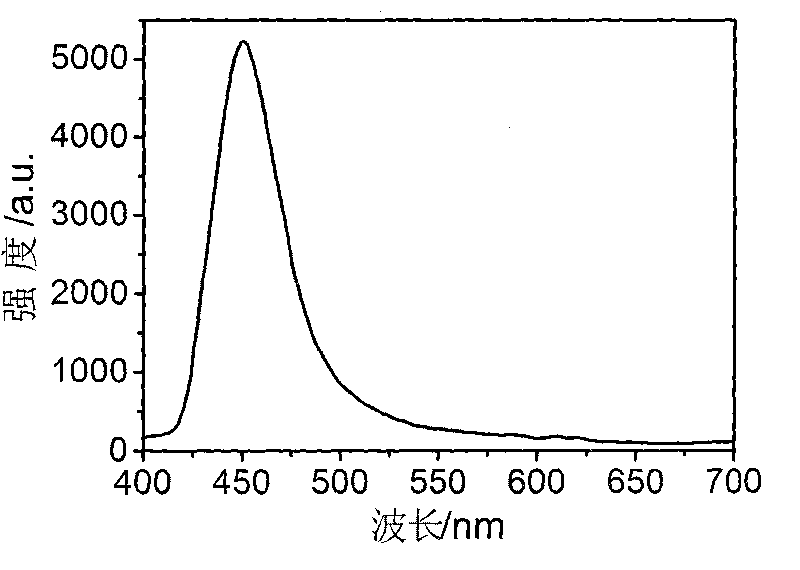

[0025] According to the chemical formula Ca 0.98 SiO 3 :0.02Eu 2+ Weigh Ca(NO 3 ) 2 4H 2 O(A.R.)0.98mol, H 2 SiO 3 (A.R.)1mol and Eu(NO 3 ) 3 ·6H 2 O (A.R.) 0.02mol; Take by weighing respectively 0.1wt% surfactant sodium dodecylbenzene sulfonate and flux H of the total mass of the above medicines 3 BO 3 ; Will weigh the good Ca (NO 3 ) 2 4H 2 O, H 2 SiO 3 , Eu(NO 3 ) 3 ·6H 2 O, surfactant and ligand NH 4 HCO 3 (The ratio of the reactant to the ligand is 1:3), and then ball milling is carried out. During the ball milling, the lubricant acetone is added, and the amount of the lubricant added is limited to be kept dispersed by the ball milling system until the reactant and the ligand are completely reacted; Suction filtration, washing, and drying to obtain the precursor powder; after mixing the precursor powder and flux uniformly, calcining under the reducing atmosphere provided by the combustion of activated carbon powder, the calcining temperature is 1250°C,...

Embodiment 2

[0027] According to the chemical formula Ca 0.96 SiO 3 :0.04Eu 2+ Weigh Ca(NO 3 ) 2 4H 2 O(A.R.)0.96mol, H 2 SiO 3 (A.R.)1mol and Eu(NO 3 ) 3 ·6H 2 O (A.R.) 0.04mol; Take by weighing respectively the surfactant sodium dodecylbenzene sulfonate of 0.4wt% of the total mass of the above medicines and the mixed flux H 3 BO 3 and MgF 2 (the mixing mass ratio is 1:1); the Ca(NO 3 ) 2 4H 2 O, H 2 SiO 3 , Eu(NO 3 ) 3 ·6H 2 O, surfactants and ligands (NH 4 ) 2 CO 3 (The ratio of the reactant to the ligand is 1:2) and then ball milled. Add lubricant acetone during ball milling. The amount of lubricant added is limited to be kept dispersed by the ball milling system until the reactant and the ligand are completely reacted; Suction filtration, washing, and drying to obtain the precursor powder; after mixing the precursor powder and flux uniformly, calcining under the reducing atmosphere provided by the combustion of activated carbon powder, the calcining temperature i...

Embodiment 3

[0029] According to the chemical formula Ca 0.94 SiO 3 :0.06Eu 2+ Weigh Ca(NO 3 )2 4H 2 O(A.R.)0.94mol, H 2 SiO 3 (A.R.)1mol and Eu(NO 3 ) 3 ·6H 2 O (A.R.) 0.06mol; Take by weighing respectively the surfactant sodium dodecylbenzene sulfonate of 0.7wt% of the total mass of the above medicines and the mixed flux H 3 BO 3 and Li 2 CO 3 (the mixing mass ratio is 1:1); the Ca(NO 3 ) 2 4H 2 O, H 2 SiO 3 , Eu(NO 3 ) 3 ·6H 2 O, surfactant and ligand C 2 h 2 o 4 (The ratio of the reactant to the ligand is 1:2) and then ball milled. Add lubricant acetone during ball milling. The amount of lubricant added is limited to be kept dispersed by the ball milling system until the reactant and the ligand are completely reacted; Suction filtration, washing, and drying to obtain the precursor powder; after mixing the precursor powder and flux uniformly, calcining under the reducing atmosphere provided by the combustion of activated carbon powder, the calcining temperature is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com