Molybdenite concentrate suspended-state roasting process and equipment

A roasting process and suspension roasting furnace technology, applied in the direction of improving process efficiency, can solve problems such as unfavorable development of molybdenum industry, poor roasting quality, flue gas pollution, etc., and achieve fast chemical reaction rate, short roasting time, and prolong life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

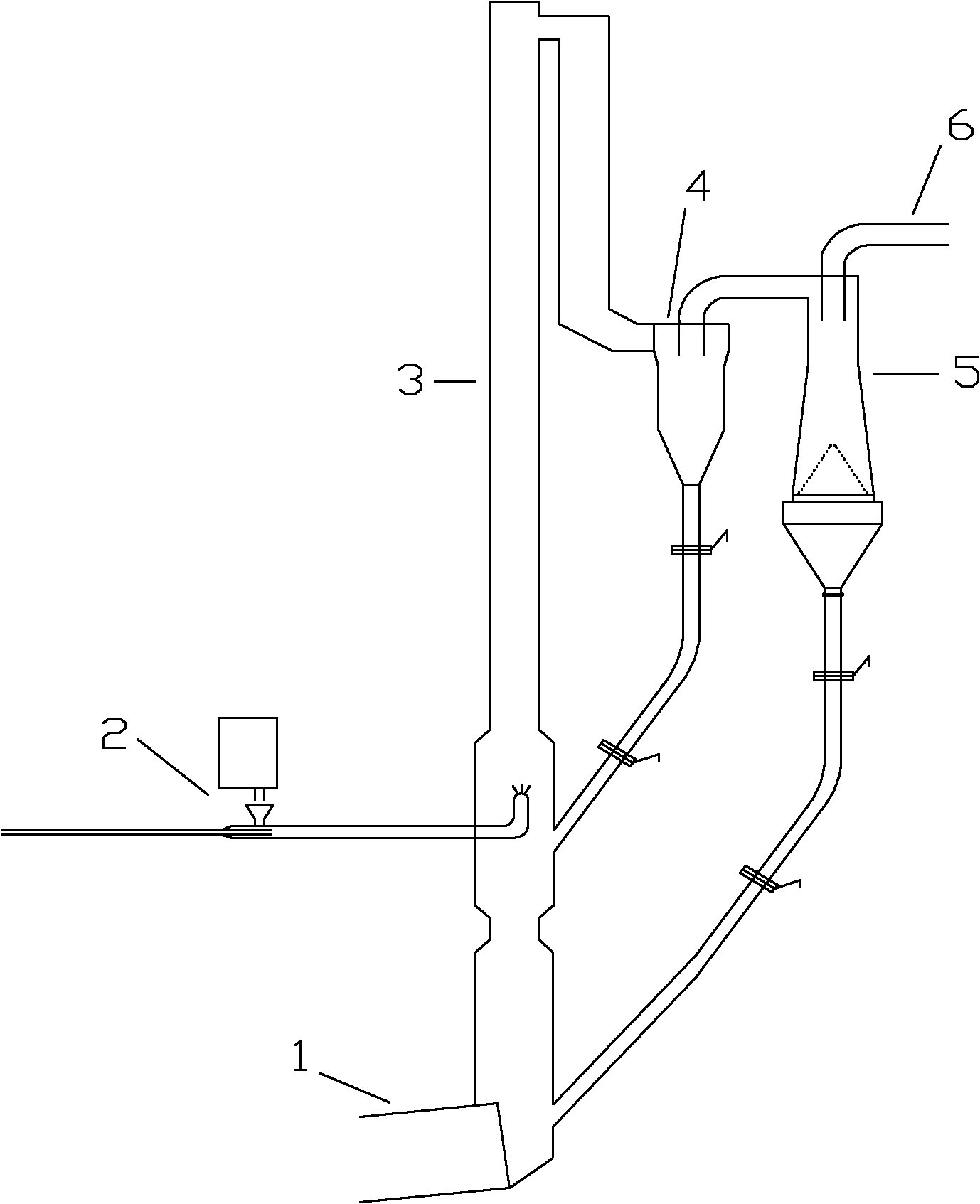

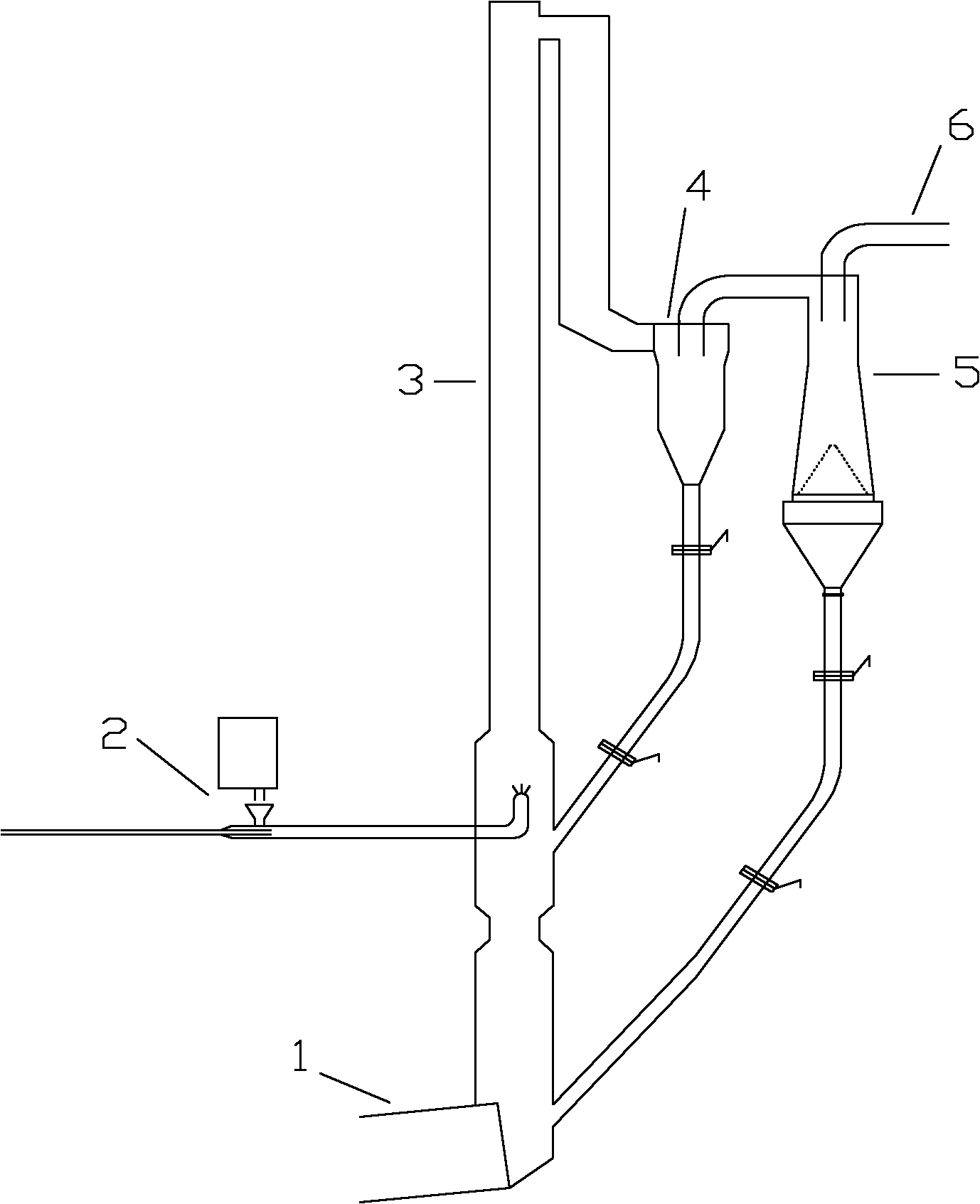

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0031] The molybdenite concentrate roasting process in suspension state comprises the following steps:

[0032] In the first step, the molybdenum fine powder is sent to the suspension roasting furnace system by compressed air through the air feeding and spraying device 2, and the heat exchange is completed in the heat exchange area, with 800kg of feed per hour, the temperature in the heat exchange area is 600°C, and the residence time is 7s ;

[0033] In the second step, after heat exchange, an oxidative desulfurization reaction occurs in the reaction zone of the suspension roaster system to generate high-sulfur calcine. The temperature in the reaction zone is 720°C, the wind speed is 15m / s, and the most probable residence time is 2 to 15s, including Sulfur content reduced from 35% to 10%;

[0034] The third step is to set the temperature of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com