Composite fuel cell

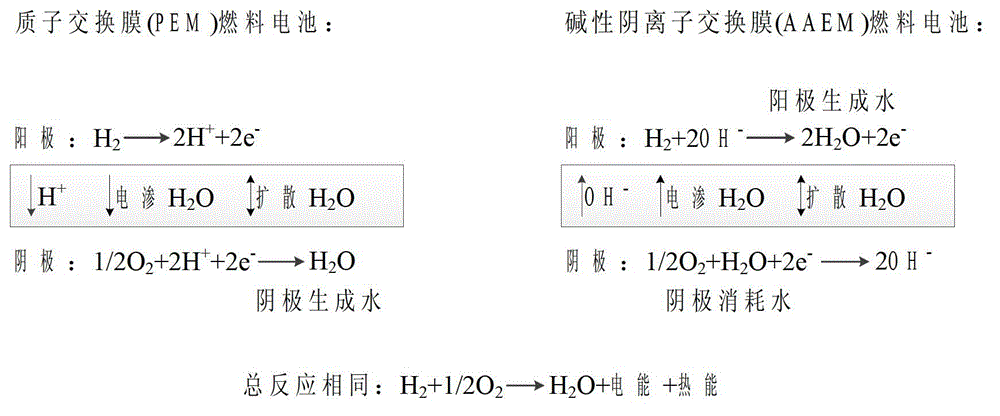

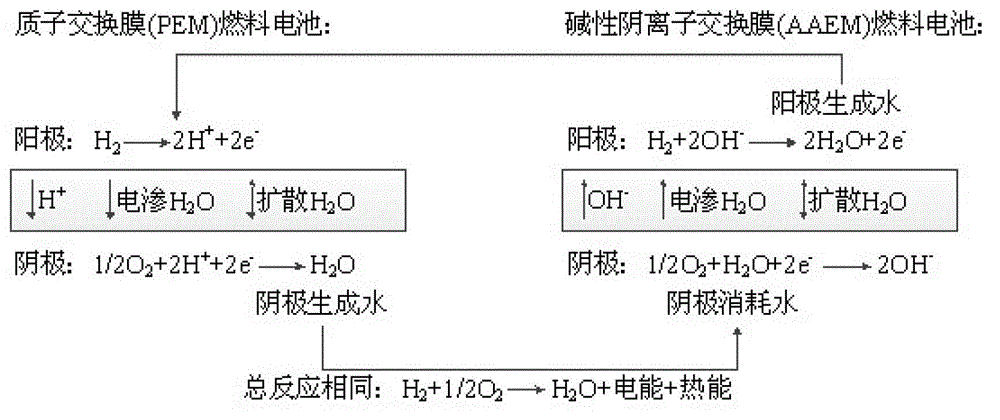

A fuel cell and composite technology, applied in the direction of fuel cells, fuel cell additives, solid electrolyte fuel cells, etc., can solve problems affecting the working efficiency of fuel cells, complex water and heat management, etc., to achieve simple water and heat management, chemical reaction The effect of fast speed and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

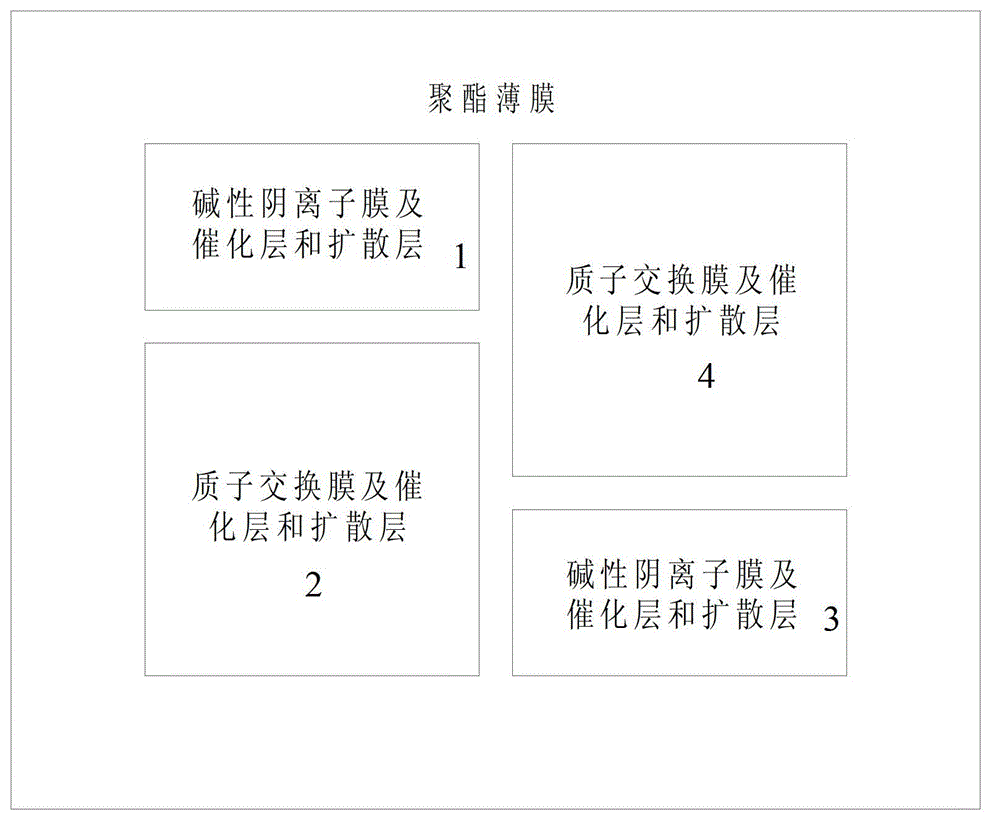

[0035] In this embodiment, methanol is used as fuel, and experiments are carried out on the fuel cell using the PEM membrane alone, the fuel cell using the AAEM membrane alone and the novel composite fuel cell of the present invention. In the new hybrid fuel cell, select the attached image 3 In the structure shown in -5, two exchange membranes are respectively selected to form a composite fuel cell, an alkaline anion membrane and a catalytic layer and a diffusion layer 1, an alkaline anion membrane and a catalytic layer and a diffusion layer 3, a proton exchange membrane and a catalytic layer and Diffusion layer 2, proton exchange membrane and catalytic layer and diffusion layer 4. PEM membrane part adopts 117 membrane, the anode catalyst is carbon-based platinum ruthenium alloy, the cathode catalyst is carbon-based platinum, and the total reaction activation area is 8.167cm 2 . AAEM film part adopts A201 film, its thickness is made and The 117 membrane is the same, the...

Embodiment 2

[0039] In this example, under different current densities, when methanol and hydrogen are used as fuels (that is, methanol and hydrogen are used as the anode fluid, and air is used as the cathode fluid), the PEM membrane fuel cell is used alone, the amount of water required for the anode to be humidified and The amount of water that needs to be drained from the cathode; using the AAEM membrane fuel cell alone, the amount of water that needs to be humidified at the cathode and the amount of water that needs to be drained from the anode, as well as the amount of water that needs to be humidified and drained from the corresponding part of the new composite fuel cell.

[0040] When methanol is used as fuel, the data are as follows:

[0041] Table 1 The amount of water required for humidification of the tested fuel cell (g / s)

[0042]

[0043] Table 2 The amount of water to be drained by the tested fuel cell (g / s)

[0044]

[0045] As can be seen from the above data, the nov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com