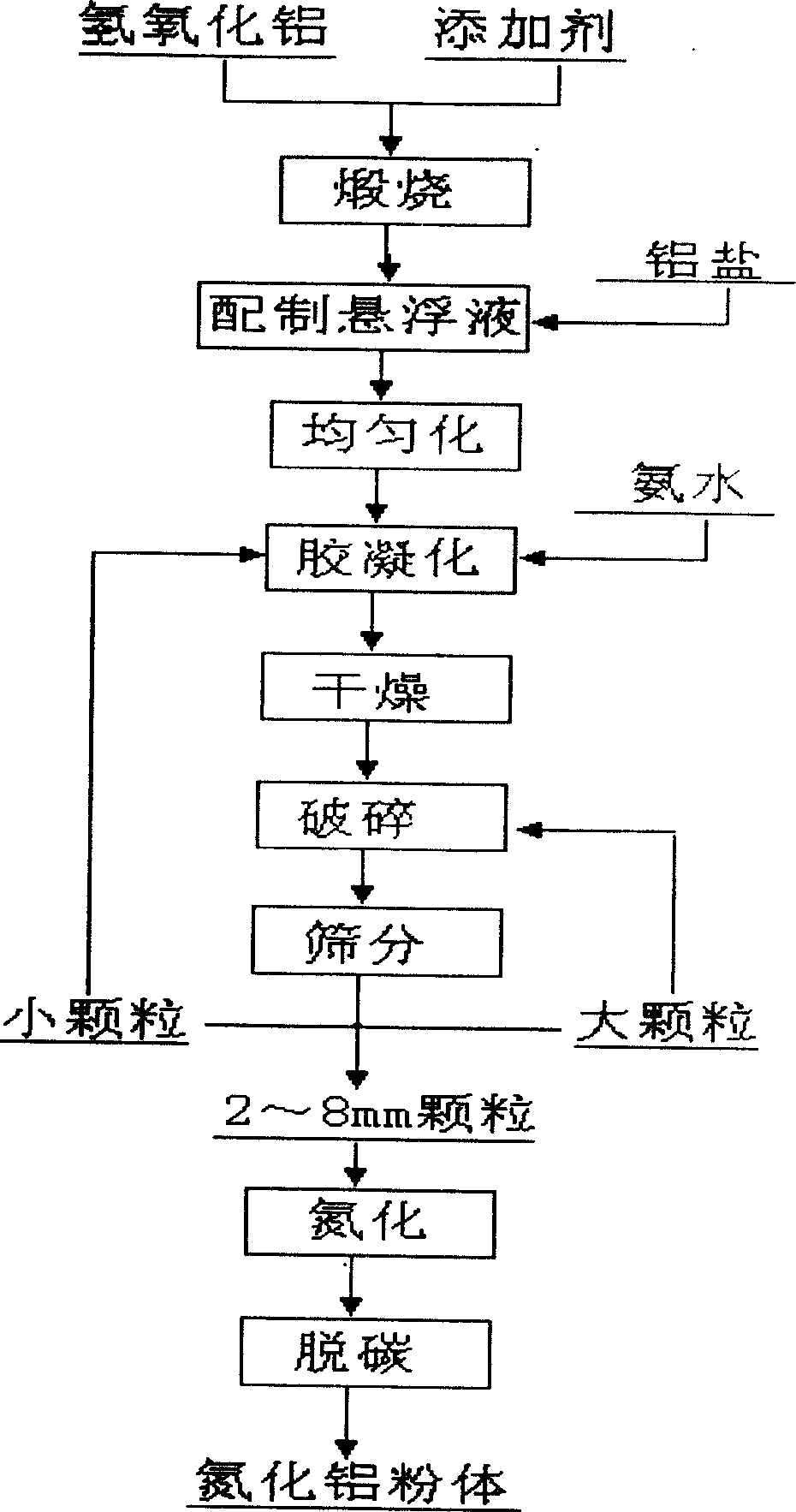

Method for preparing aluminium nitride powder by carbothermic reduction method

A reduction method, aluminum nitride technology, applied in chemical instruments and methods, nitrogen compounds, inorganic chemistry, etc., can solve the problems of high reaction temperature and long reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Using industrial aluminum hydroxide as raw material, firstly mix 1000g of aluminum hydroxide with 15g of boric acid additive, calcined at 500°C for 6 hours, take 200g of calcined alumina, put it into a 1000ml beaker, add 200ml of deionized water , then add 25g of aluminum nitrate, then add the surfactant solution, adjust the pH value between 2 and 3 with nitric acid, add 70g of superfine carbon powder while stirring, after adding the carbon powder, stir for 20 minutes, slowly add ammonia water, Adjust the pH value to between 12. At this time, the slurry becomes a whole gel-like substance. The gel is dried in a drying oven at 90° C., and the dried gel is broken into small particles of 2 to 8 mm. Put the small particles into the vacuum carbon tube furnace, control the flow of nitrogen gas at 20-25ml / s, the sintering temperature is 1600°C, and the time is 3 hours. The calcined material is pulverized, oxidized and decarburized in a muffle furnace at 750°C, and finally gray ...

Embodiment 2

[0022] The aluminum oxide in example 1 is replaced by superfine aluminum hydroxide, and the calcining temperature is 1550° C., and the same result is also obtained.

Embodiment 3

[0024] Using industrial aluminum hydroxide as raw material, firstly mix 1000g of aluminum hydroxide with 15g of boric acid additive, calcined at 900°C for 2 hours, take 200g of calcined alumina, put it into a 1000ml beaker, add 200ml of deionized water , then add 25g of aluminum nitrate, then add surfactant solution, adjust the pH value between 2 with nitric acid, add 70g of superfine carbon powder while stirring, after adding the carbon powder, stir for 30 minutes, slowly add ammonia water, adjust the pH When the value is between 13, the slurry becomes a whole gel-like substance, and the gel is dried in a drying oven at 90°C, and the dried gel is broken into small particles of 2-8mm, and the small particles Put it into a vacuum carbon tube furnace, control the nitrogen flow rate at 20-25ml / s, the sintering temperature at 1800°C, and the sintering time for 2 hours. The calcined material is pulverized, oxidized and calcined in a muffle furnace at 800°C for 2 hours for decarburi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com