Rapid QPQ (Quench-Polish-Quench) treatment method of application electric field and equipment thereof

A processing method and technology of processing equipment, applied in the direction of metal material coating process, coating, solid diffusion coating, etc., can solve problems such as being unfavorable to improve wear resistance, corrosion resistance, thin infiltration layer, etc., and reduce composite processing. effect of time, reducing nitriding temperature, increasing concentration and activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

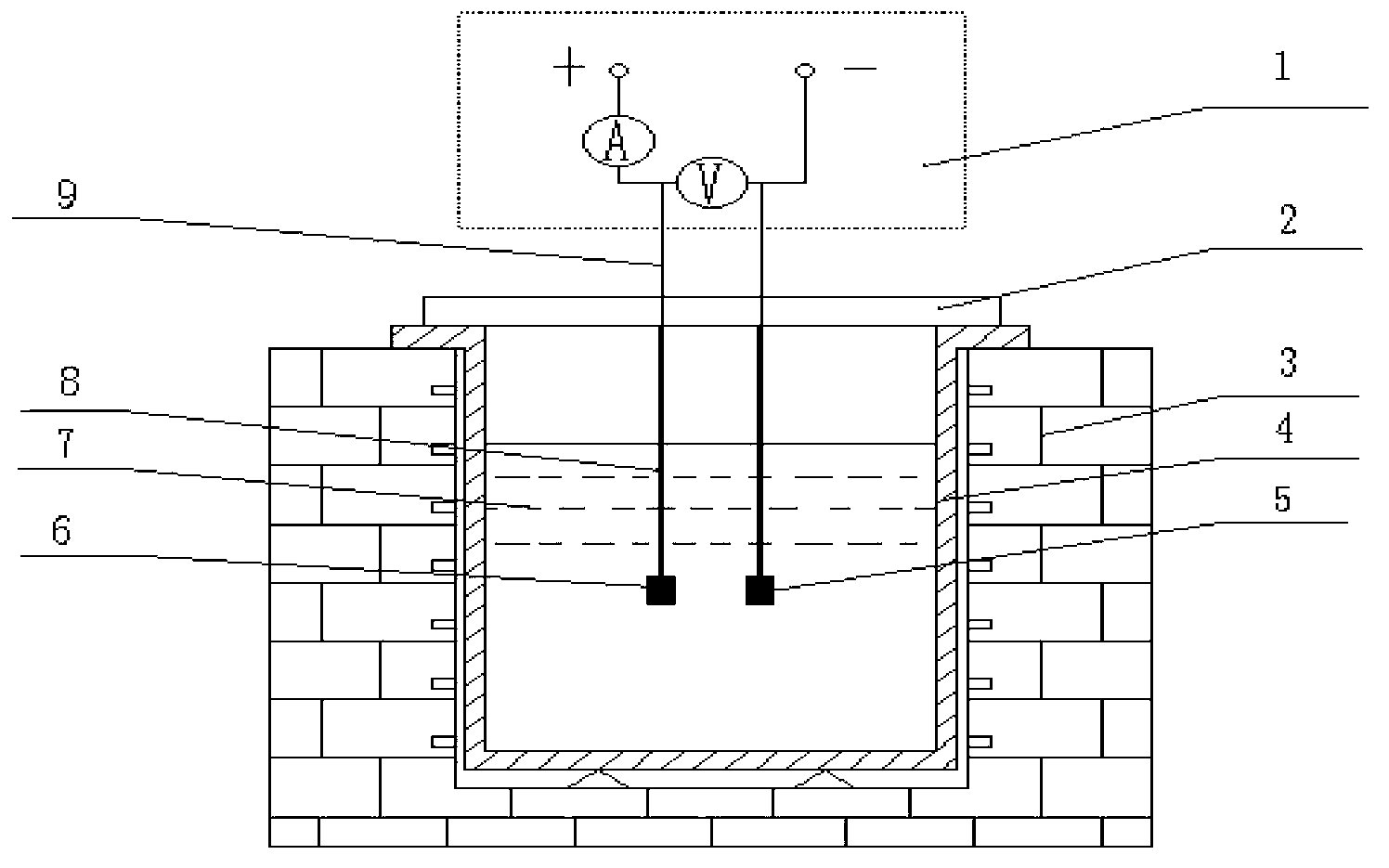

[0031] A fast QPQ processing method for applying an electric field, the method may further comprise the steps:

[0032] 1) Smooth the surface of sample 5 to be treated with 400#~2000# SiC sandpaper in sequence;

[0033] 2) Use absolute ethanol or acetone to perform ultrasonic cleaning on the sample 5 to be treated for 15 minutes to remove oil and impurities on the surface of the sample 5 to be treated, and dry it for use;

[0034] 3) Put the sample 5 to be treated into the resistance furnace for pre-oxidation for 20~30min;

[0035] 4) Heat the pit furnace 3 to 450-500°C for heat preservation, and heat up to the nitriding temperature after the nitriding base salt in the crucible 4 is fully melted;

[0036] 5) Using the base salt as the nitriding agent, place a plate-shaped electrode 6 designed according to the layman’s design of the sample 5 to be treated in the salt bath, use this electrode as the positive electrode, and the sample 5 to be processed as the negative electrode,...

Embodiment 2)

[0042] 1) Smooth the surface of sample 5 to be treated with 400#~2000# SiC sandpaper in sequence;

[0043] 2) Use absolute ethanol or acetone to perform ultrasonic cleaning on the sample 5 to be treated for 15 minutes to remove oil and impurities on the surface of the sample 5 to be treated, and dry it for use;

[0044] 3) Put the sample 5 to be treated into the resistance furnace for pre-oxidation for 20~30min;

[0045] 4) Heat the pit furnace 3 to 450-500°C for heat preservation, and heat up to the nitriding temperature after the nitriding base salt in the crucible 4 is fully melted;

[0046]5) Use the base salt as the nitriding agent, place a plate-shaped electrode 6 designed according to the shape of the sample to be treated in the salt bath, use the plate-shaped electrode 6 as the positive electrode, and use the part as the negative electrode. The two electrodes are parallel to each other. The distance between the electrode 6 and the sample 5 to be treated is 20mm, and t...

Embodiment 3)

[0051] 1) Smooth the surface of sample 5 to be treated with 400#~2000# SiC sandpaper in sequence;

[0052] 2) Use absolute ethanol or acetone to perform ultrasonic cleaning on the sample 5 to be treated for 15 minutes to remove oil and impurities on the surface of the sample 5 to be treated, and dry it for use;

[0053] 3) Put the sample 5 to be treated into the resistance furnace for pre-oxidation for 20~30min;

[0054] 4) Heat the pit furnace 3 to 450-500°C for heat preservation, and heat up to the nitriding temperature after the nitriding base salt in the crucible 4 is fully melted;

[0055] 5) Using the base salt as the nitriding agent, place a plate-shaped electrode 6 designed according to the shape of the sample 5 to be treated in the salt bath, use the electrode as the positive electrode, and the sample 5 to be processed as the negative electrode, and the two electrodes are parallel to each other. The distance between the shape electrode 6 and the sample 5 to be treate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com