Preparation method of Ca-alpha-SiAlON:Eu<2+> fluorescent nanoribbon fiber

A fluorescent nano-fiber technology is applied in the field of preparation of fluorescent nano-belt fibers, and achieves the effects of low nitridation temperature, good application prospect and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

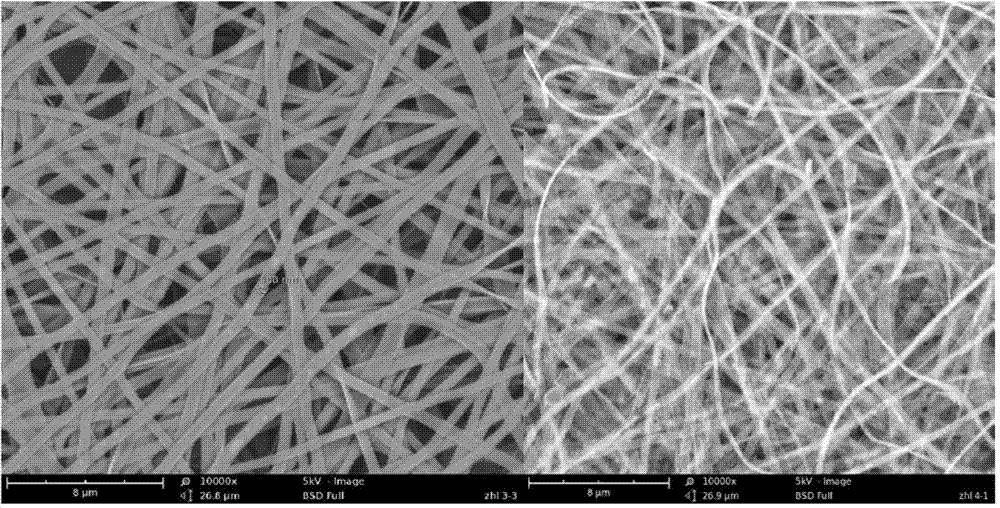

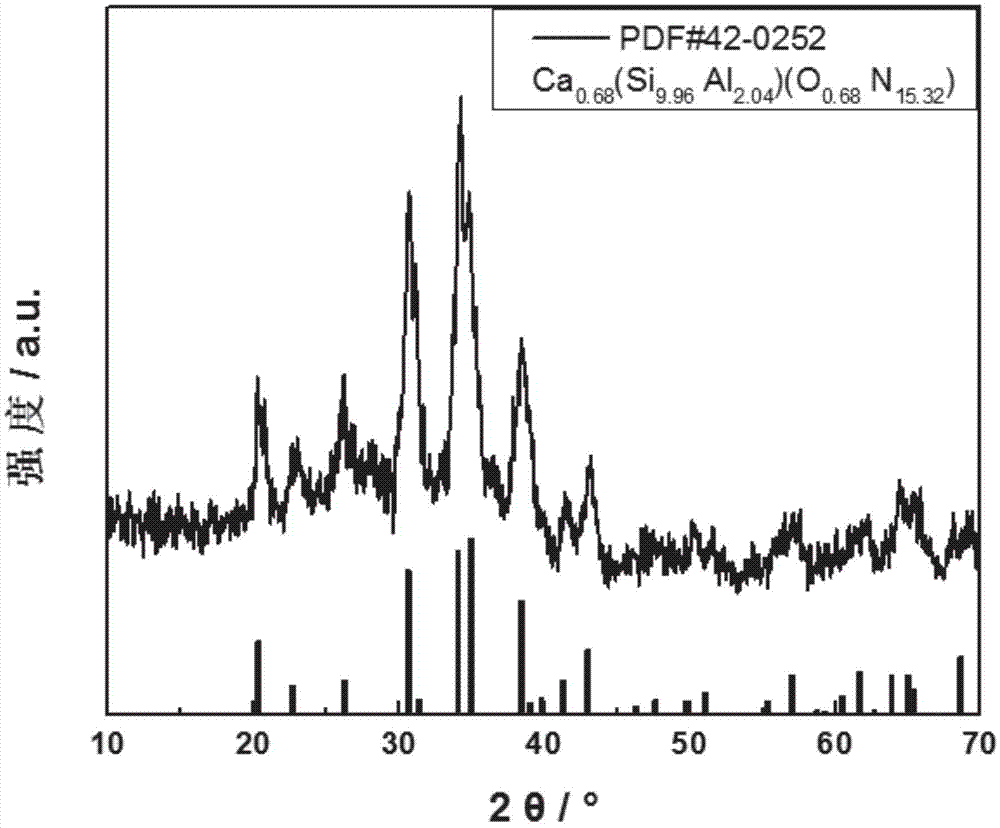

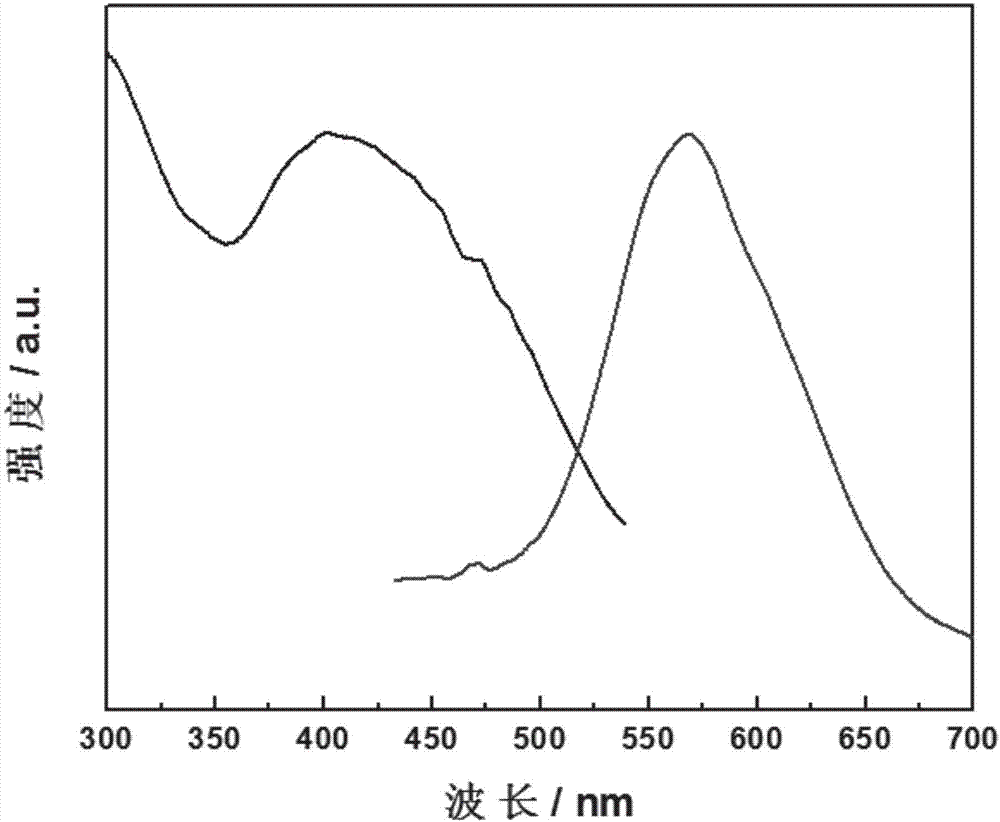

[0024] 3.4mmol calcium nitrate, 11.34mmol aluminum nitrate and 0.56mmol europium nitrate were dissolved in alcohol-water mixed solvent (V 醇 / V 水 =8:2). Add 2.5ml tetraethyl orthosilicate dropwise into the above solution under stirring, and add 2.0g polyvinyl butyral (M w =170000) to adjust the viscosity of the solution, continue stirring for 1 h, and finally obtain a uniform and transparent spinning solution. Put the prepared spinning solution into the syringe and put it into the peristaltic pump. Connect the needle to the anode of the high-voltage generator, use aluminum foil as the receiving device, connect to the cathode, the voltage is 10kv, the distance between the spinning needle and the receiving aluminum foil is 15cm, the propulsion speed of the peristaltic pump is 10μl / min, and the relative humidity is controlled at 10%. . After 8 hours of electrospinning, a uniform layer of white fibers was collected on the receiving aluminum foil. The fibers obtained by electro...

Embodiment 2

[0026] Dissolve 1.7mmol calcium nitrate, 5.67mmol aluminum nitrate and 0.28mmol europium nitrate in 40ml alcohol-water mixed solvent (V 醇 / V 水 =7:1). Add 4.8ml tetraethyl orthosilicate dropwise to the above solution under stirring, and add 1.6g polyvinyl butyral (M w =250000) to adjust the viscosity of the solution, continue stirring for 1 h, and finally obtain a uniform and transparent spinning solution. Put the prepared spinning solution into the syringe and put it into the peristaltic pump. Connect the needle to the anode of the high-voltage generator, use aluminum foil as the receiving device, connect to the cathode, the voltage is 9KV, the distance between the spinning needle and the receiving aluminum foil is 18cm, the propulsion speed of the peristaltic pump is 8μl / min, and the relative humidity is controlled at 12%. . After 8 hours of electrospinning, a uniform layer of white fibers was collected on the receiving aluminum foil. The fibers obtained by electrospinni...

Embodiment 3

[0028] Dissolve 0.9mmol calcium nitrate, 2.7mmol aluminum nitrate and 0.15mmol europium nitrate in alcohol-water mixed solvent (V 醇 / V 水 =7:1). Add 2.5ml tetraethyl orthosilicate dropwise into the above solution under stirring, and add 2.0g polyvinyl butyral (M w=170000) to adjust the viscosity of the solution, continue stirring for 1 h, and finally obtain a uniform and transparent spinning solution. Put the prepared spinning solution into the syringe and put it into the peristaltic pump. Connect the needle to the anode of the high-voltage generator, use aluminum foil as the receiving device, and connect to the cathode, the voltage is 10KV, the distance between the spinning needle and the receiving aluminum foil is 15cm, the propulsion speed of the peristaltic pump is 8μl / min, and the relative humidity is controlled at 10%. . After 8 hours of electrospinning, a uniform layer of white fibers was collected on the receiving aluminum foil. The fibers obtained by electrospinni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com