Aluminum nitride powder as well as preparation method and application thereof

A technology of aluminum nitride and powder, which is applied in the field of aluminum nitride powder and its preparation, can solve the problems of low purity of the synthetic product aluminum nitride powder, uneven mixing of raw materials, incomplete solid-gas reaction, etc. Achieve the effects of accelerating the nitriding reaction process, shortening the reaction time, and reducing the activation energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

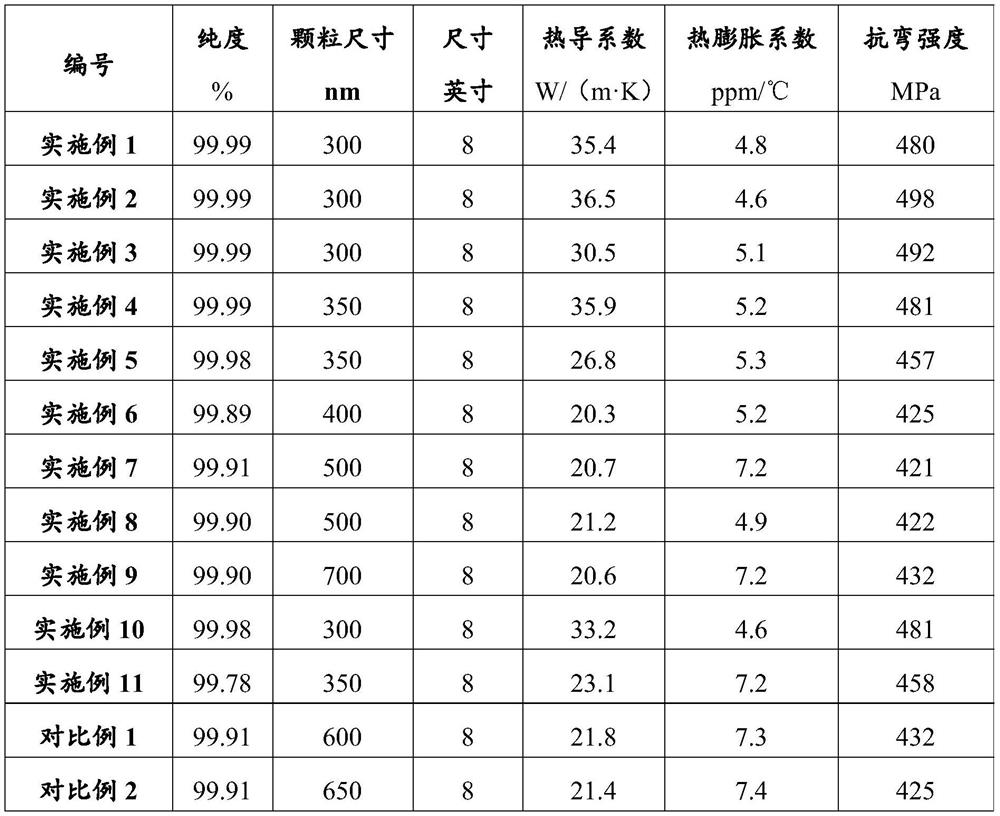

Examples

preparation example Construction

[0031] In order to solve the problem of low purity of the aluminum nitride powder produced by the carbothermal reduction method in the prior art, the present invention uses activated carbon as the carbon source reducing agent, and uses the porogen to form the activated carbon into a nanostructure, thereby obtaining a three-dimensional porous structure. Precursor, the precursor is supported by the nano-activated carbon structure, and the aluminum element is uniformly dispersed in the pores of the nano-activated carbon structure, which not only makes the mixing of the aluminum element and the activated carbon more uniform, the resulting aluminum nitride has higher purity, but also makes the nano-activated carbon structure As a template for aluminum nitride, it imparts a nanostructure to aluminum nitride. Specifically, the preparation method of aluminum nitride powder of the present invention comprises the following steps:

[0032] performing a hydrothermal reaction on an aluminu...

Embodiment 1

[0061] Embodiment 1 provides a kind of preparation method of aluminum nitride powder, and this preparation method comprises the following steps:

[0062] (1) Add 50mL of ultrapure water to a reaction kettle with a lining volume of 100mL, then add aluminum nitrate, pitch coke activated carbon and potassium hydroxide, wherein the mass ratio of aluminum nitrate, pitch coke activated carbon and potassium hydroxide is aluminum nitrate: Pitch coke activated carbon: KOH=1:0.12:0.23 (potassium hydroxide: 0.8g), mix evenly, seal, keep warm at 150°C for 25 hours, then cool to room temperature to obtain the hydrothermal product;

[0063] (2) Heat the hydrothermal product to 100°C while stirring, and keep warm to evaporate the solution to dryness. This process takes about 20 hours to obtain nano-carbon supported Al 2 o 3 Precursor;

[0064] (3) Precursor, urea and ammonium molybdate are uniformly mixed according to the mass ratio of precursor: urea: ammonium molybdate=1:0.6:0.03, placed...

Embodiment 2

[0067] Embodiment 2 provides a kind of preparation method of aluminum nitride powder, and the difference of this preparation method and the preparation method of embodiment 1 is that the mass ratio of aluminum nitrate, pitch coke activated carbon and potassium hydroxide is aluminum nitrate: pitch coke activated carbon: KOH=1:0.24:0.45 (the amount of aluminum nitrate is the same as in Example 1). The aluminum nitride powder obtained in this example was made into a ceramic sintered body by the same method as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com