Magnetic abrasive material and preparation method thereof

A magnetic abrasive and nitriding technology, which is applied in chemical instruments and methods, and other chemical processes, can solve the problems of easy shedding of abrasive grains, and achieve the effects of simple preparation method, low energy consumption, and low nitriding temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

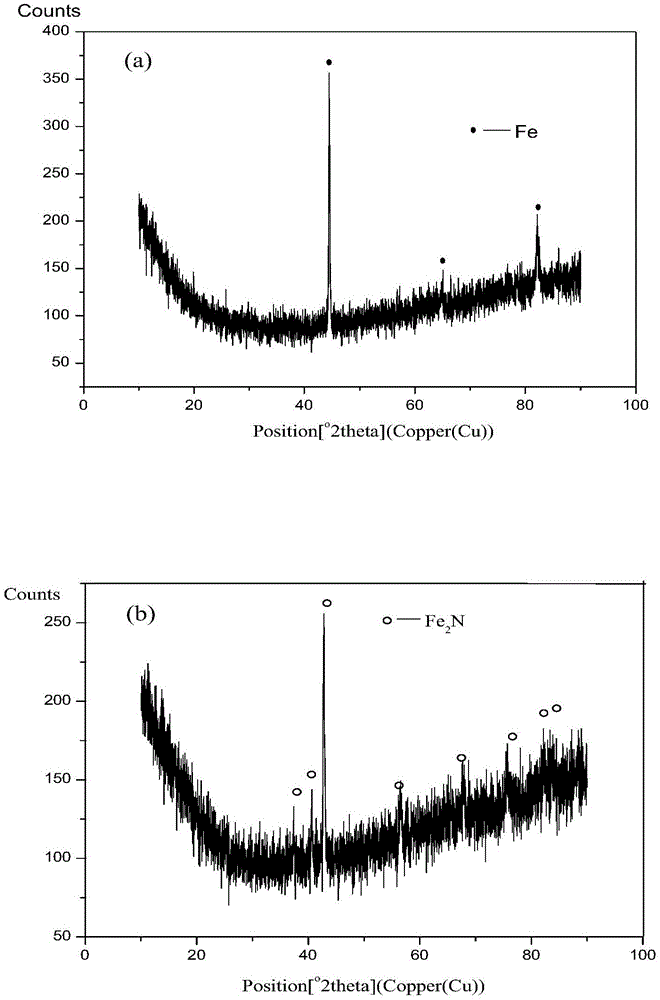

[0022] Put 40-mesh iron powder into a high-temperature furnace at 450°C, pass in nitrogen gas to replace the air in the furnace and connecting parts, then turn off the nitrogen gas, and then pass in ammonia gas to replace the nitrogen in the furnace chamber, so that the pressure in the furnace chamber is 0.5MPa, after that, Control the flow rate of ammonia gas to 1L / min. After the nitriding reaction has been carried out for 3 hours, turn off the ammonia gas, and replace the ammonia gas in the furnace cavity and connecting parts with nitrogen gas. Take it out from the furnace cavity, cool it in water, take out the powder and dry it to obtain magnetic abrasive material A. The ammonia gas flowing out of the high temperature furnace is absorbed by dilute sulfuric acid.

[0023] Abrasive performance test conditions are:

[0024] Workpiece to be processed: 45# steel flat workpiece, initial surface roughness Ra is 1.43μm; magnetic pole: cylindrical φ16mm×L30mm, magnetic induction in...

Embodiment 2

[0027] Put 40-mesh iron powder into a high-temperature furnace at 450°C, pass in nitrogen gas to replace the air in the furnace and connecting parts, then turn off the nitrogen gas, and then pass in ammonia gas to replace the nitrogen in the furnace chamber, and then make the furnace chamber pressure 0.5MPa, Control the flow rate of ammonia gas to 1L / min. After the nitriding reaction has been carried out for 3 hours, turn off the ammonia gas, and replace the ammonia gas in the furnace cavity and connecting parts with nitrogen gas. Take it out from the furnace cavity, cool it to room temperature in the air, and obtain the magnetic abrasive material B. The ammonia gas flowing out of the high temperature furnace is absorbed by dilute sulfuric acid.

[0028] Abrasive performance test conditions are:

[0029] Processed workpiece: No. 1 TC titanium alloy plate, initial surface roughness Ra is 2.70μm; magnetic pole: cylindrical φ16mm×30mm, magnetic induction: 700-800mT, rotation spe...

Embodiment 3

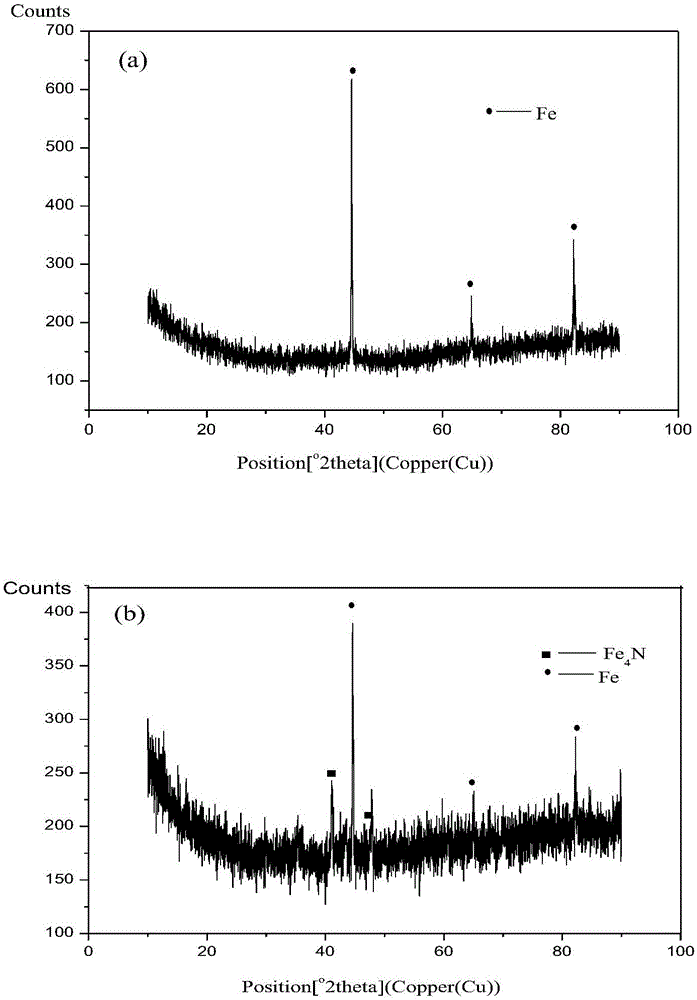

[0032] Nitriding was carried out with 60-mesh iron powder, and other preparation conditions were the same as in Example 1 to obtain Magnetic Abrasive C.

[0033] According to the same abrasive performance testing conditions as in Example 1, the magnetic abrasive C is used for grinding, so that the surface roughness of the workpiece to be processed is 0.15 μm.

[0034] According to the same abrasive performance testing conditions as in Example 2, the No. 1 TC titanium alloy plate has an initial surface roughness Ra of 4.33 μm, and other conditions remain unchanged. Grinding with magnetic abrasive C makes the surface roughness of the processed workpiece 0.054 μm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com