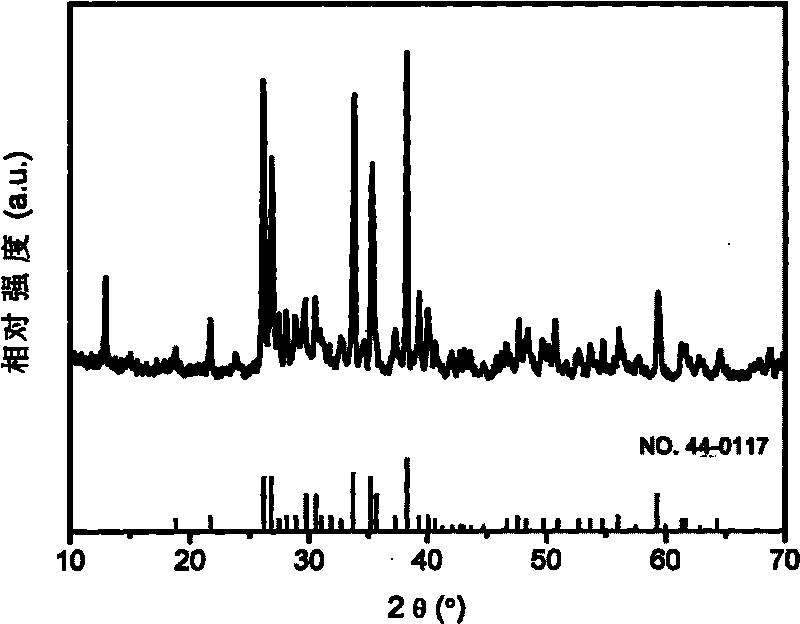

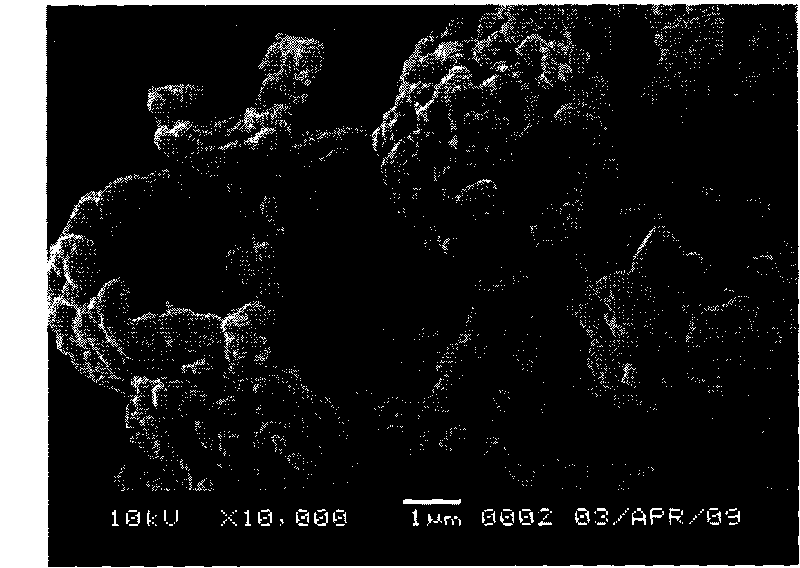

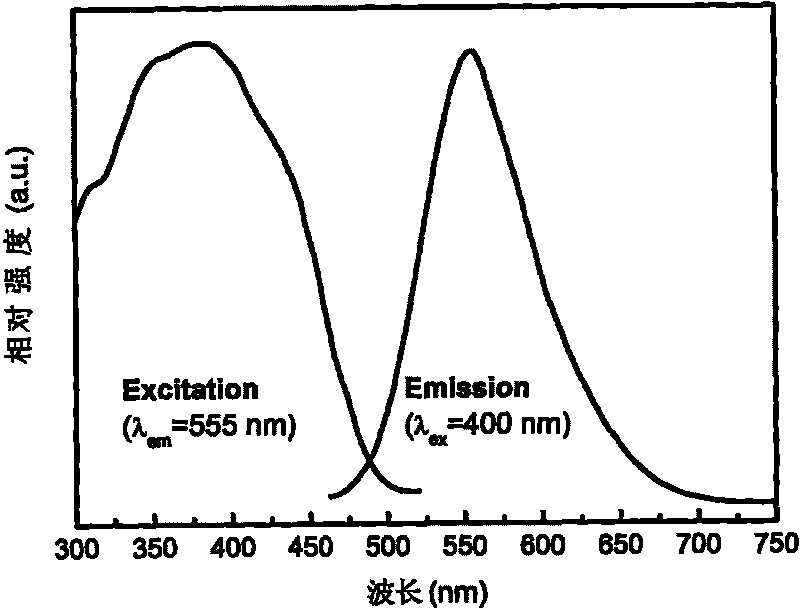

Method for preparing porous spherical CaSi2O2N2:Eu2 plus fluorescent powder

A porous spherical and fluorescent powder technology, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of easy agglomeration, large size, and irregular shape of product particles, and achieve difficult agglomeration, simple production equipment, and maintain a porous spherical shape appearance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Dissolve calcium chloride, europium chloride, and polyethylene glycol in 200mL water to form solution A; dissolve sodium carbonate, polyethylene glycol, and sodium lauryl sulfate in 300mL water to form solution B, keep in solution A The concentration of calcium chloride is the same as that of sodium carbonate in solution B, which is 0.1M; the molar ratio of europium chloride to calcium chloride is 0.03:1; the concentration of polyethylene glycol in solutions A and B is the same, which is 1g / L; the concentration of sodium lauryl sulfate is 1 × 10 -2M; quickly pour the prepared A solution into solution B, stir for 1 min, keep at 20°C, pH 7 and let stand for 18h, wash the obtained precipitate with water for 5 times, and dry at 80°C for 2h to obtain (Eu, Ca )CO 3 hollow microspheres;

[0031] Take 1g (Eu, Ca)CO 3 The hollow microspheres are dispersed in 200mL water, and the molar ratio of CaCO at room temperature 3 : SiO 2 = 1:2 Add 0.05M Na dropwise 2 SiO 3 Solutio...

Embodiment 2

[0034] Dissolve calcium chloride, europium chloride and polyethylene glycol in 400mL water to form solution A; dissolve sodium carbonate, polyethylene glycol and sodium lauryl sulfate in 600mL water to form solution B; keep in solution A The concentration of calcium chloride is the same as that of sodium carbonate in solution B, both being 0.1M; the molar ratio of europium chloride to calcium chloride is 0.03:1; the concentration of polyethylene glycol in solutions A and B is the same, both being 1.5g / L; the concentration of sodium lauryl sulfate is 2×10 -2 M; quickly pour the prepared solution A into solution B, stir for 5 minutes, keep at 25°C, pH 8 and let it stand for 24 hours, wash the obtained precipitate with water for 5 times, and dry at 80°C for 2 hours to obtain (Eu, Ca )CO 3 hollow microspheres;

[0035] Take 1.2g (Eu, Ca)CO 3 The hollow microspheres are dispersed in 300mL water, and the molar ratio of CaCO at room temperature 3 : SiO 2 =1.2:2 Add 0.1M Na drop...

Embodiment 3

[0038] Dissolve calcium chloride, europium chloride, polyethylene glycol 6000 in 400mL water to form solution A; dissolve sodium carbonate, polyethylene glycol 6000, and sodium lauryl sulfate in 600mL water to form solution B; keep the solution The concentration of calcium chloride in A is the same as that of sodium carbonate in solution B, which is 0.2M; the molar ratio of europium chloride to calcium chloride is 0.05:1; the concentration of polyethylene glycol in solution A and B is the same, both are 1.5g / L; the concentration of sodium lauryl sulfate is 2×10 -2 M, quickly pour the prepared solution A into solution B, stir for 1 min, keep at 20°C, pH 8 and leave to age for 24h, wash the obtained precipitate with water 8 times, and dry at 100°C for 0.5h to obtain (Eu, Ca)CO 3 hollow microspheres;

[0039] Take 1.2g (Eu, Ca)CO 3 The hollow microspheres are dispersed in 300mL water, and the molar ratio of CaCO at room temperature 3 : SiO 2 =1.2:2 Add 0.1M Na dropwise 2 Si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com