Nitrogen-contained rare earth magnetic powder and preparation method thereof

A rare earth magnetic powder and rare earth technology, applied in the field of preparation of nitrogen-containing rare earth magnetic powder, can solve the problems of small powder diameter, large specific surface area of magnetic powder, large surface activity, etc., to prevent oxidation of magnetic powder, short nitriding time, and high nitriding temperature low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

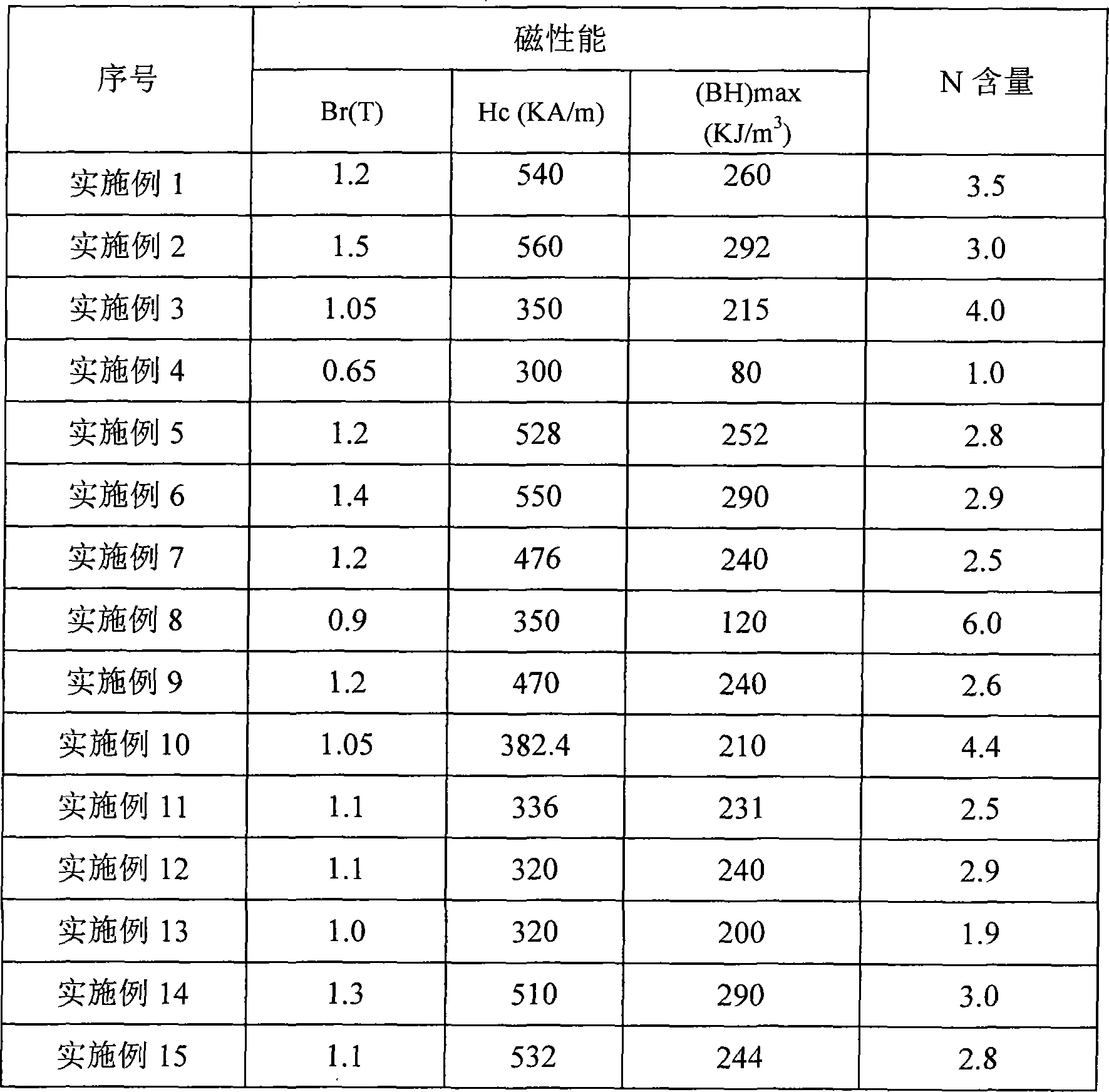

Embodiment 1

[0022] The prepared raw materials are smelted in the crucible, and then the alloy liquid is cast on the rotating water-cooled roller in a planar flow through the casting trough to form Sm-Fe alloy cast sheets with an average thickness of 0.05-1.0 mm. The obtained Sm-Fe alloy casting sheet is added with 15wt% organic compound, wherein the organic compound composition is 30wt% of the cene compound (ferrocene: Sm=1: 15) and the balance is methyl alcohol and butanol (methanol: Butanol=5:1), vacuumize to less than 3×10 -3 NH after Pa 3 -H 2 To 5atm, incubate at 450°C for 1 hour to obtain the composition Sm 2 Fe 17 N 3.5The nitrogen-containing rare earth alloy was cast into flakes, and then ball-milled into magnetic powder with a particle size of 0.3-50 μm. The magnetic properties and nitrogen content of the magnetic powder are shown in Table 1.

Embodiment 2

[0024] The prepared raw materials are smelted in the crucible, and then the alloy liquid is cast on the rotating water-cooled roller in a planar flow through the casting trough to form Sm-Fe alloy cast sheets with an average thickness of 0.05-1.0 mm. The obtained Sm-Fe alloy casting sheet is added with 6wt% organic compound, wherein the organic compound added composition is 70wt% of the cene compound (ferrocene: Sm=1:33) and the balance is urea and yellow blood salt ( Urea: yellow blood salt = 5: 1), vacuumize to less than 3 × 10 -3 N after Pa 2 Mix the gas to 6atm, keep it at 450°C for 3 hours to obtain the composition Sm 2 Fe 17 N 3.0 The nitrogen-containing rare earth alloy was cast into flakes, and then ball-milled into magnetic powder with a particle size of 0.3-50 μm. The magnetic properties and nitrogen content of the magnetic powder are shown in Table 1.

Embodiment 3

[0026] The prepared raw materials are smelted in the crucible, and then the alloy liquid is cast on the rotating water-cooled roller in a planar flow through the casting trough to form Nd-Fe alloy cast sheets with an average thickness of 0.05-1.0 mm. The obtained Nd-Fe alloy cast piece is broken into, add 14wt% organic compound, wherein the organic compound addition composition is the cene compound (ferrocene: cene Nd=1: 19) of 42wt% and the balance is carboxylic acid rare earth and Rare earth naphthenate (rare earth carboxylate: rare earth naphthenate = 5:1), vacuumize to less than 3×10 -3 NH after Pa 3 -H 2 Mix the gas to 2atm, keep it at 450°C for 2 hours to obtain the composition of Nd 2 Fe 17 N 4.0 The nitrogen-containing rare earth alloy was cast into flakes, and then ball-milled into magnetic powder with a particle size of 0.3-50 μm. The magnetic properties and nitrogen content of the magnetic powder are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com