Nitrogen-containing iron-based amorphous nanocrystalline soft magnetic alloy and preparation method thereof

A nanocrystalline soft magnetic, iron-based amorphous technology, applied in the direction of magnetic materials, magnetic objects, metal material coating processes, etc., can solve the problems of low nitriding temperature, short nitriding time, difficult processing, etc. The effect of low temperature, short nitriding time and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] Preparation of nitrogen-containing iron-based amorphous soft magnetic alloy strips, the chemical formula is (Fe 90 Zr 7 B 3 ) 99.75 N 0.25 .

[0062] (1) Elemental Fe, Zr and B are uniformly mixed according to the above stoichiometric ratio, and an arc melting furnace is used to prepare a parent soft magnetic alloy ingot with uniform composition.

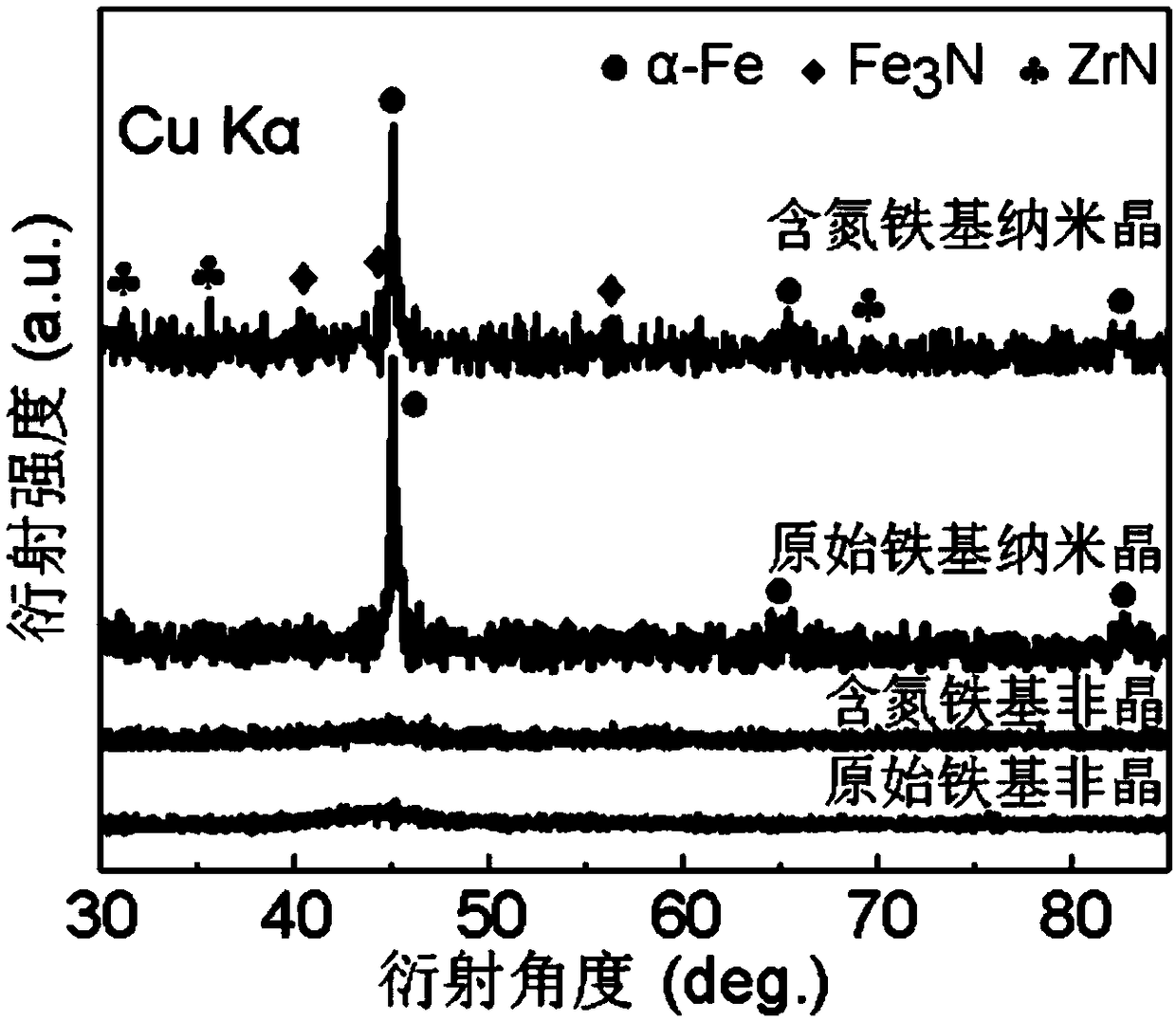

[0063] (2) Grinding the surface impurities of the parent soft magnetic alloy ingot obtained in step (1) with a grinding wheel, and then placing it in a single-roll quick quenching device to obtain the original iron-based amorphous soft magnetic alloy strip (original iron-based amorphous) . The obtained original iron-based amorphous soft magnetic alloy strip has a smooth surface and a thickness of 23 μm, and the XRD pattern is as follows figure 1 As shown, it has a completely amorphous structure.

[0064] (3) Plasma nitriding treatment is carried out to the original iron-based amorphous soft magnetic alloy strip that st...

Embodiment 2

[0069] The nitrogen-containing iron-based amorphous soft magnetic alloy strip prepared in Example 1 is subjected to high vacuum heat treatment to obtain a nitrogen-containing iron-based amorphous nanocrystalline soft magnetic alloy strip (nitrogen-containing iron-based nanocrystalline), and the heat treatment temperature is 630 ° C , the processing time is 1h.

[0070] The nitrogen content of the obtained nitrogen-containing iron-based amorphous nanocrystalline soft magnetic alloy strip is 900ppm, the saturation magnetic induction is 1.63T, and the corrosion rate is 0.11mm / a under the condition that the corrosion medium is 0.5M NaCl solution, which has excellent Saturation magnetic induction and corrosion resistance.

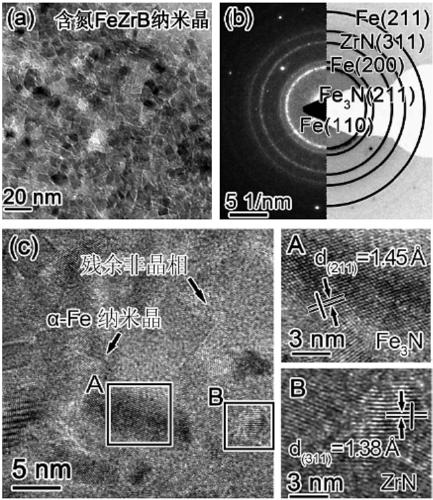

[0071] The XRD pattern of the obtained nitrogen-containing iron-based amorphous nanocrystalline soft magnetic alloy strip is as follows figure 1 As mentioned, the transmission electron microscope photos are as follows image 3 As shown, the grain size of the n...

Embodiment 3

[0073] Preparation of nitrogen-containing iron-based amorphous soft magnetic alloy strips, the chemical formula is (Fe 84 Nb 7 B 9 ) 99.85 N 0.15 .

[0074] (1) Elemental Fe, Nb and B are uniformly mixed according to the above stoichiometric ratio, and an arc melting furnace is used to prepare a parent soft magnetic alloy ingot with uniform composition.

[0075] (2) Grinding the surface impurities of the parent soft magnetic alloy ingot obtained in step (1) with a grinding wheel, and then placing it in a single-roll quenching device to obtain iron-based amorphous soft magnetic alloy strips. The obtained iron-based amorphous soft magnetic alloy strip has a smooth surface and a completely amorphous structure.

[0076] (3) plasma nitriding treatment is carried out to the iron-based amorphous soft magnetic alloy strip that step (2) obtains, adopting-300V pulse bias voltage, frequency is 40kHz, and duty cycle is 20%, and arc plasma source current is 50A, The nitriding tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| saturation magnetic induction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com